Liquid taking device and method

A liquid, placing tank technology, applied in sampling devices, measuring devices, sampling and other directions, can solve the problem of wasting the time of scientific researchers, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

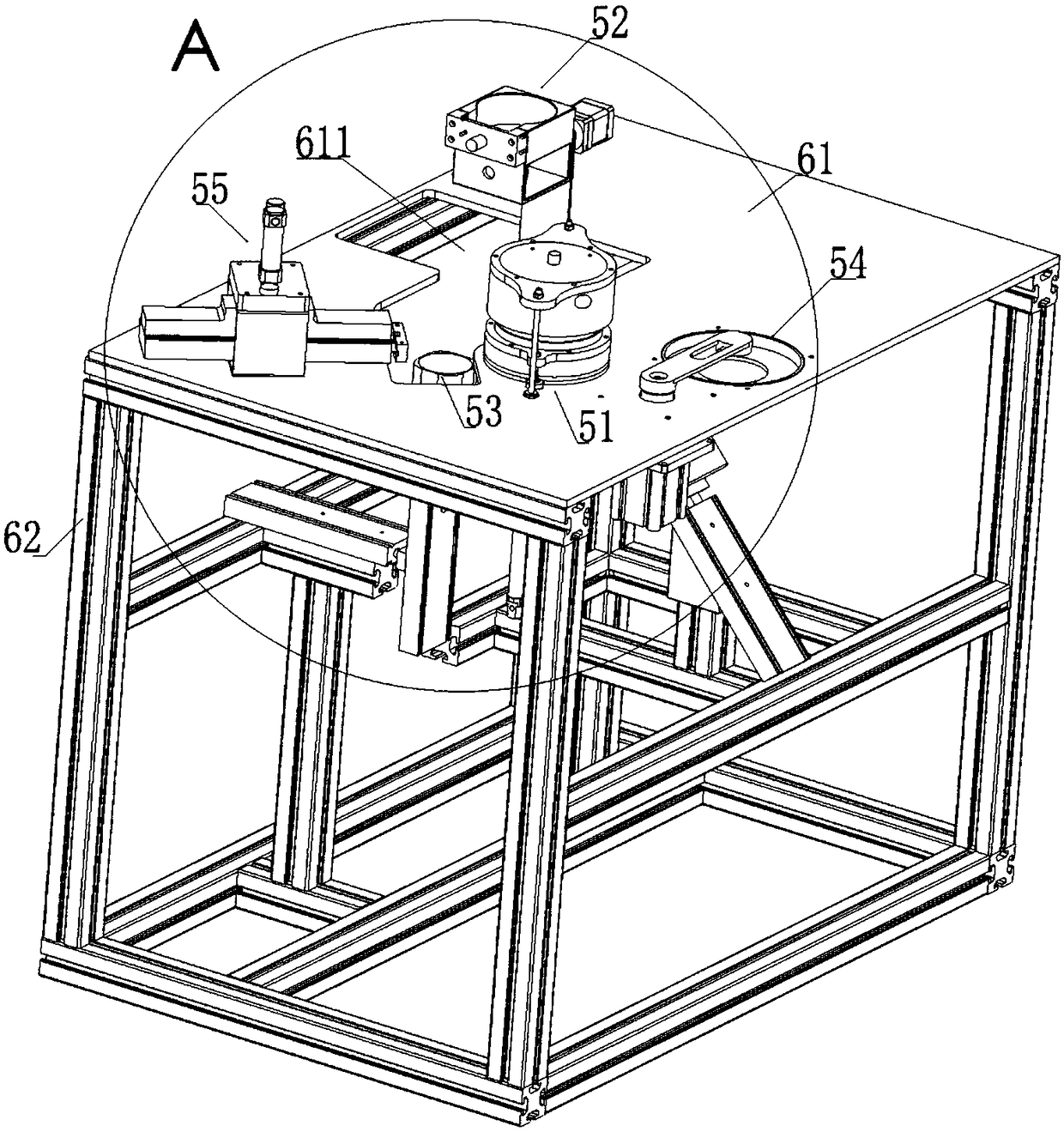

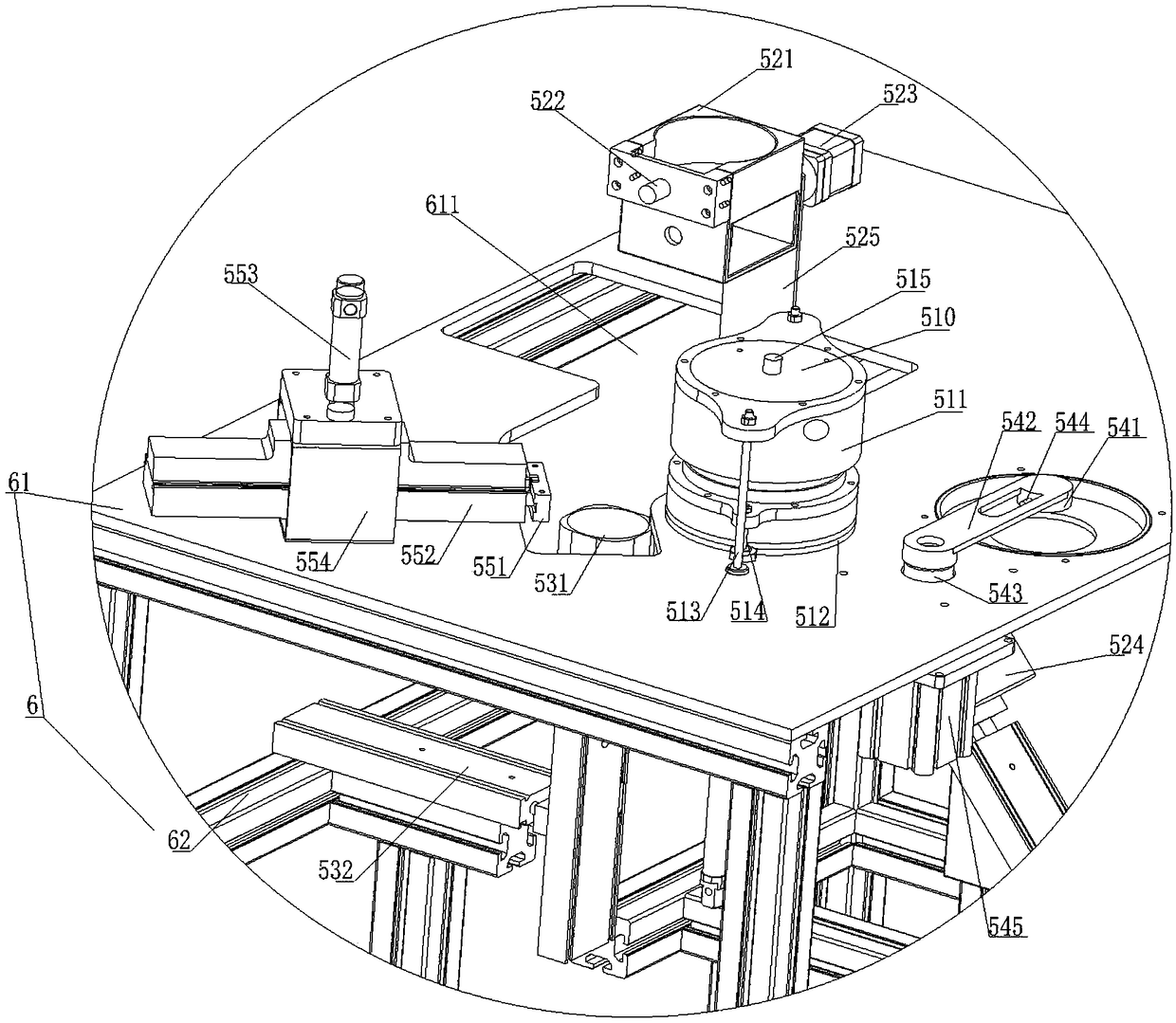

[0050] like Figure 1-2 As shown, the liquid-taking device includes a support 6, a

[0051] Filtration mechanism 51, used for filtering the mixture poured from the reagent bottle;

[0052] The pouring mechanism 52 is used to fix the reagent bottle, and by moving and rotating the reagent bottle, the mixture in the reagent bottle is poured into the inlet of the filter mechanism 51;

[0053] The liquid receiving mechanism 53 is used to fix and move the liquid receiving bottle, and the liquid receiving bottle is used to obtain the liquid filtered by the filtering mechanism 51;

[0054] Put filter paper mechanism 54, for putting into new filter paper in filter mechanism 51;

[0055] The scraper mechanism 55 is used to scrape the used filter paper out of the filter mechanism 51 from the filter mechanism 51 .

[0056] The workbench 61 is provided with an operation port 611 between the filtering mechanism 51 , the dumping mechanism 52 and the liquid contact mechanism 53 , and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com