High-temperature drilling fluid forced cooling system

A forced cooling and refrigeration system technology, applied in the field of petroleum drilling, can solve the problems of reducing the service life of downhole tools, affecting the normal use of measuring instruments, the safety of drilling operations, and affecting the performance of drilling fluids, etc., so as to save oil consumption costs and facilitate well site placement And transfer, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

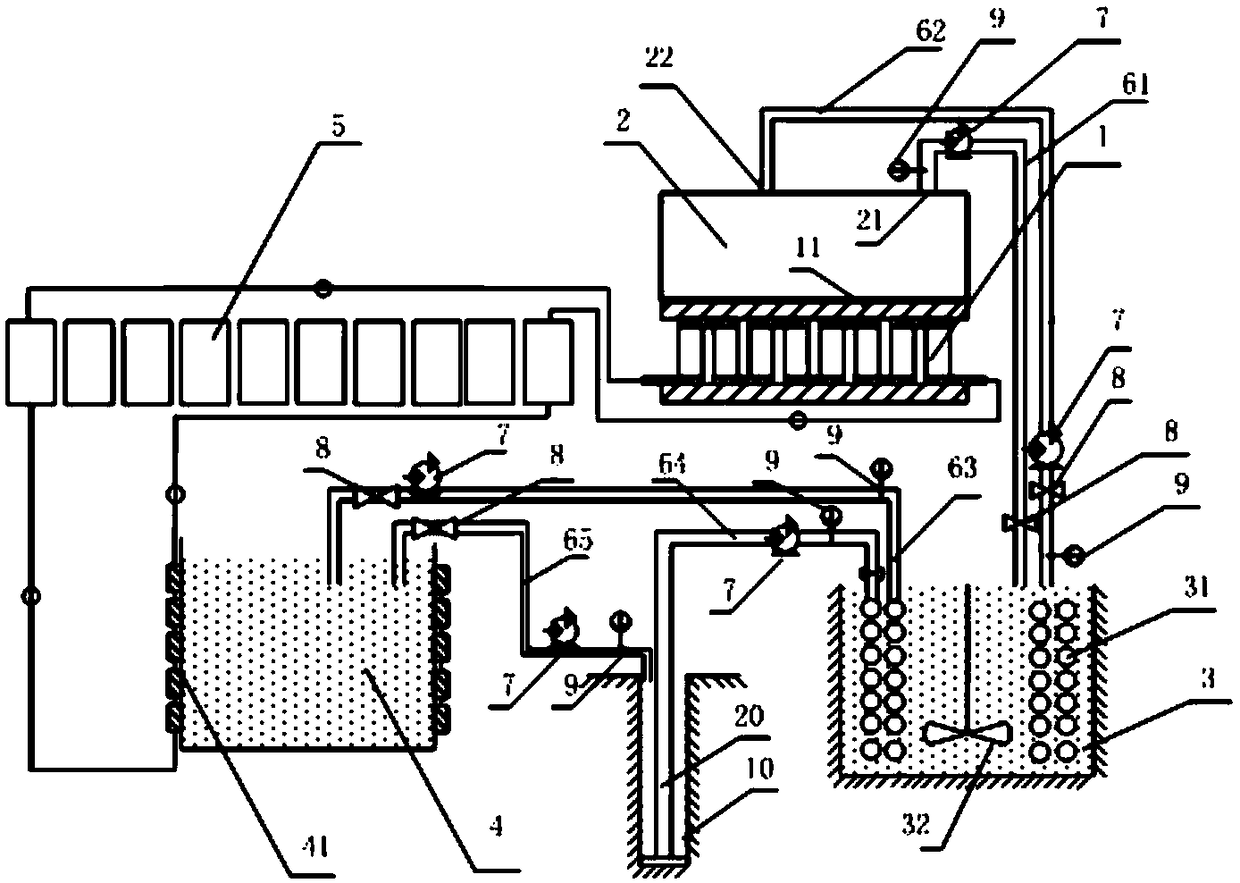

[0021] see figure 1 The high-temperature drilling fluid forced cooling system of the present invention includes a semiconductor refrigeration system 1, a brine cooling box 2, a mud cooling pool 3, a mud generating battery 4, a storage battery system 5, liquid pipelines, several pumps 7, several valves 8 and A number of temperature sensors 9.

[0022] The cold end of the semiconductor refrigeration system 1 is attached to the brine cooling box 2, and the brine cooling box 2 includes a brine outlet 21 and a brine inlet 22 respectively connected to a pipeline 61 and a pipeline 62, and the pipeline 61 and the pipeline 62 is equipped with pump 7, valve 8, temperature sensor 9, and the other end of pipeline 61 and pipeline 62 stretches in the mud cooling pool 3, as the inlet and outlet of brine in the mud cooling pool 3. The brine circulates be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com