Head soldered structure for tamping pick

A brazing and head technology, which is applied in the field of wear-resistant hammers, can solve the problems of high production cost, short service life, and poor wear resistance, and achieve the effects of improving wear resistance, prolonging service life, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

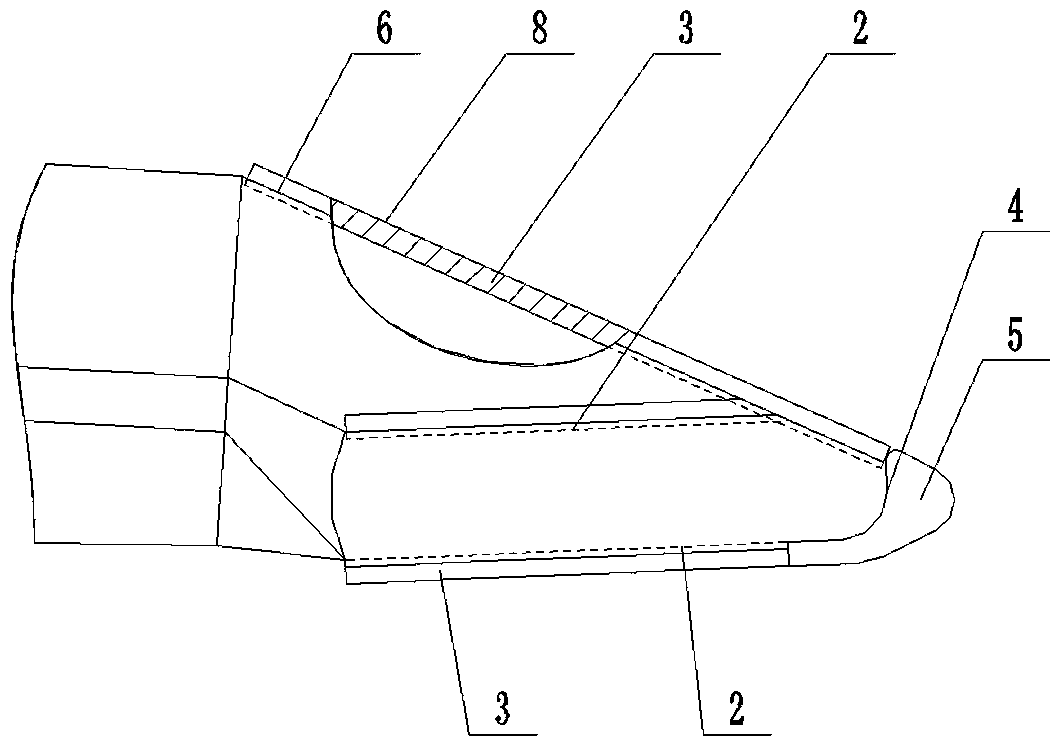

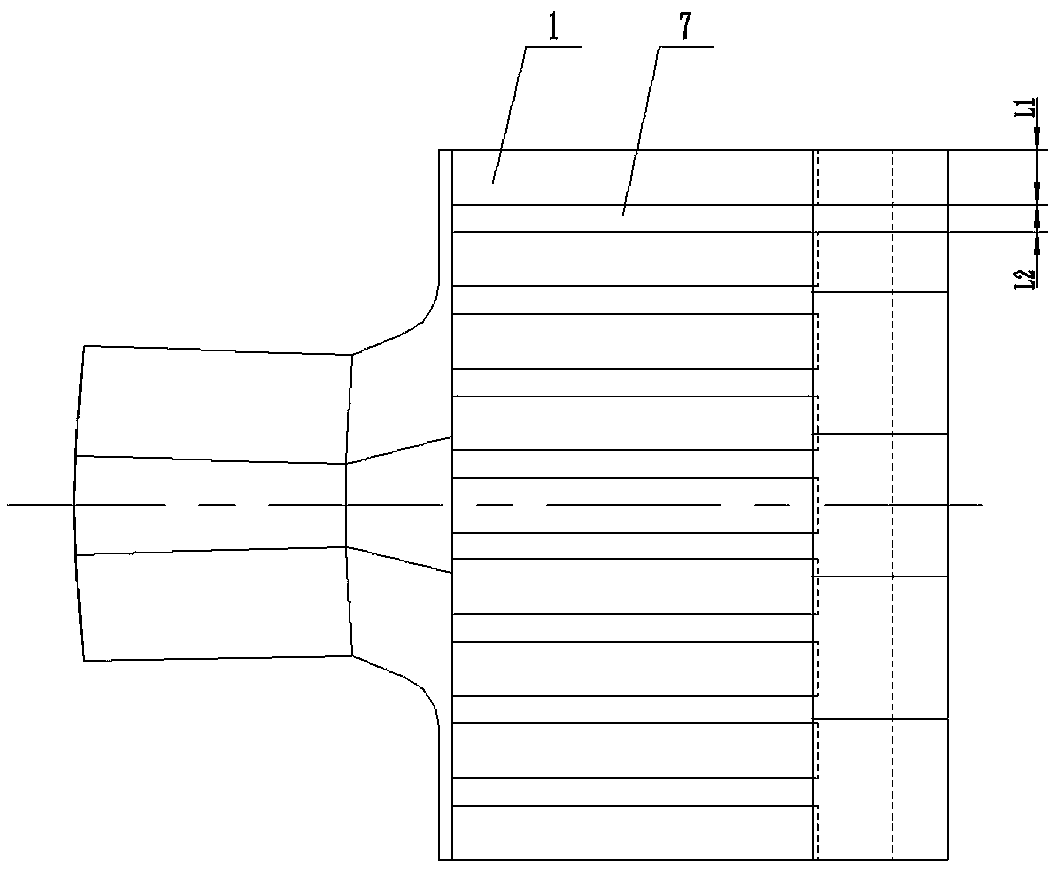

[0019] see figure 1 , figure 2 , a brazing structure of a tamper head, comprising a tamper body 6, grooves 1 with a depth exceeding the thickness of the solder 2 are arranged at intervals on the surface of the tamper body 6, and protrusions 7 are arranged between the grooves 1, and the protrusions The width of 7 is smaller than the width of the groove 1, and the first wear-resistant alloy sheet 3 is brazed with the solder 2 in the groove 1, and the shapes of the groove 1 and the first wear-resistant alloy sheet 3 are elongated, and the first The height of the upper surface 8 of the wear-resistant alloy sheet 3 is greater than the surface height of the protrusion 7, and the front end portion 4 of the hammer head b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com