Preparation method and application of nano-structural photocatalytic electrode

A nanostructure and photocatalytic technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., can solve the problems of reduced electrode performance, small microscopic contact area, weak binding force, etc., to improve the enhanced oxidation life, increase Micro contact area, the effect of improving efficiency and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

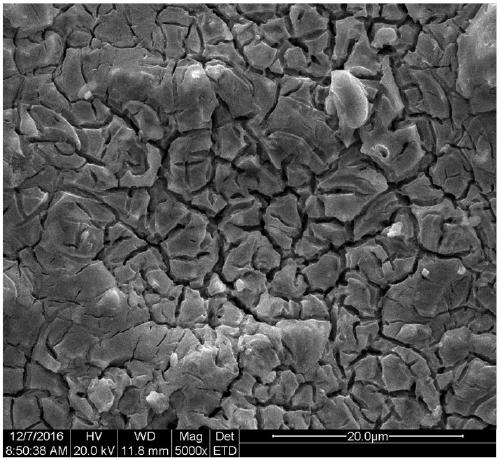

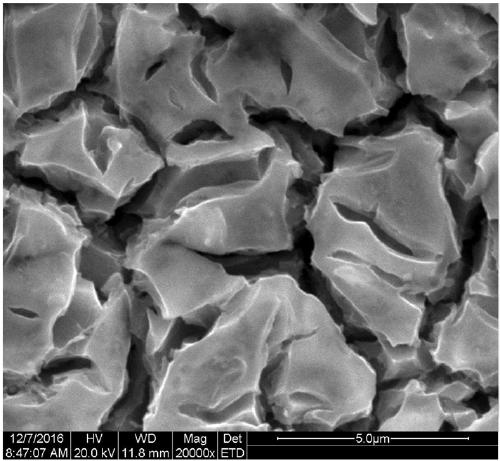

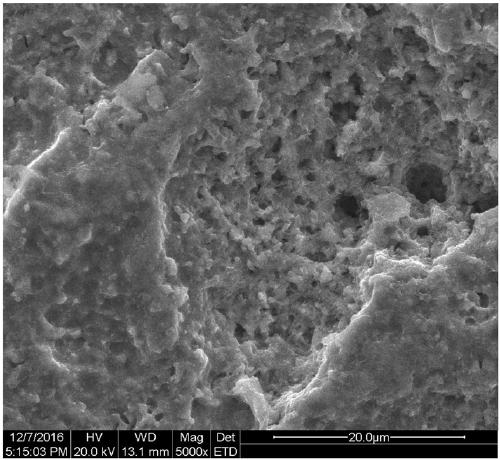

[0031] Such as Figures 1 to 4 Shown is the embodiment of the photocatalytic electrode preparation method of a kind of nanostructure of the present invention, comprises the following steps:

[0032] (1) Electrode substrate pretreatment;

[0033] (2) Configure the metal salt solution: mix RuCl 3 with TiCl x Add solvent and mix well to get RuCl 3 with TiCl x the mixture;

[0034] (3) brushing: brushing the mixed solution onto the surface of the electrode base;

[0035] (4) Baking oxidation: the electrode substrate is brushed and then dried and oxidized to form a composite oxide coating of Ru and Ti on the surface of the electrode substrate, wherein the drying temperature is 400-600°C.

[0036] Preferably, the electrodes are pure Ti electrodes.

[0037] Among them, the TiCl x is titanium chloride, preferably TiCl 3 .

[0038] In the above-mentioned technical scheme, by adopting RuCl 3 with TiCl x The mixed solution of the electrode substrate is brushed, dried and oxid...

Embodiment 2

[0045] (1) adopt the preparation method of embodiment 1 to prepare electrode, wherein Ru=6g / m 2 , the mass ratio of Ru to Ti is 20:80. The prepared electrode was tested, and the chlorine evolution potential was measured to be 1.112V, and the enhanced life was 6000min.

[0046] (2) adopt the preparation method of embodiment 1 to prepare electrode, wherein Ru=15g / m 2, the mass ratio of Ru to Ti is 40:60. The prepared electrode was tested, and the chlorine evolution potential was measured to be 1.095V, and the enhanced life was 15000min.

[0047] (3) Traditionally use butyl titanate to prepare electrodes, where Ru=20g / m 2 , the mass ratio of Ru to Ti is 40:60. The prepared electrode was tested, and the chlorine evolution potential was measured to be 1.100V, and the enhanced life was less than or equal to 10000min.

[0048] The above test results show that under the condition of similar coating quality per square meter, the strengthening life of this embodiment is greatly imp...

Embodiment 3

[0050] Get sewage sample 1 and sewage sample 2, use the electrode that the preparation method of embodiment 1 makes, carry out electrolytic treatment to sewage sample 1 and sewage sample 2 respectively, carry out the test of sewage degradation effect after electrolytic treatment (chemical oxygen demand COD test ), and compared with the treatment effect of the traditional preparation electrode using butyl titanate, the results shown in the following table are obtained:

[0051]

[0052]

[0053] The above test results show that, compared with the electrode prepared by the traditional preparation method, the electrolytic treatment of the present invention has a greatly improved sewage degradation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com