Oriented-arrayed graphenemagnesium-base alloy with ultra-high thermal conductivity and preparation method and device

A technology of oriented alignment and magnesium-based alloys, applied in the field of materials, can solve the problems of reduced chemical activity and thermal conductivity, and achieve the effect of improving high thermal conductivity and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

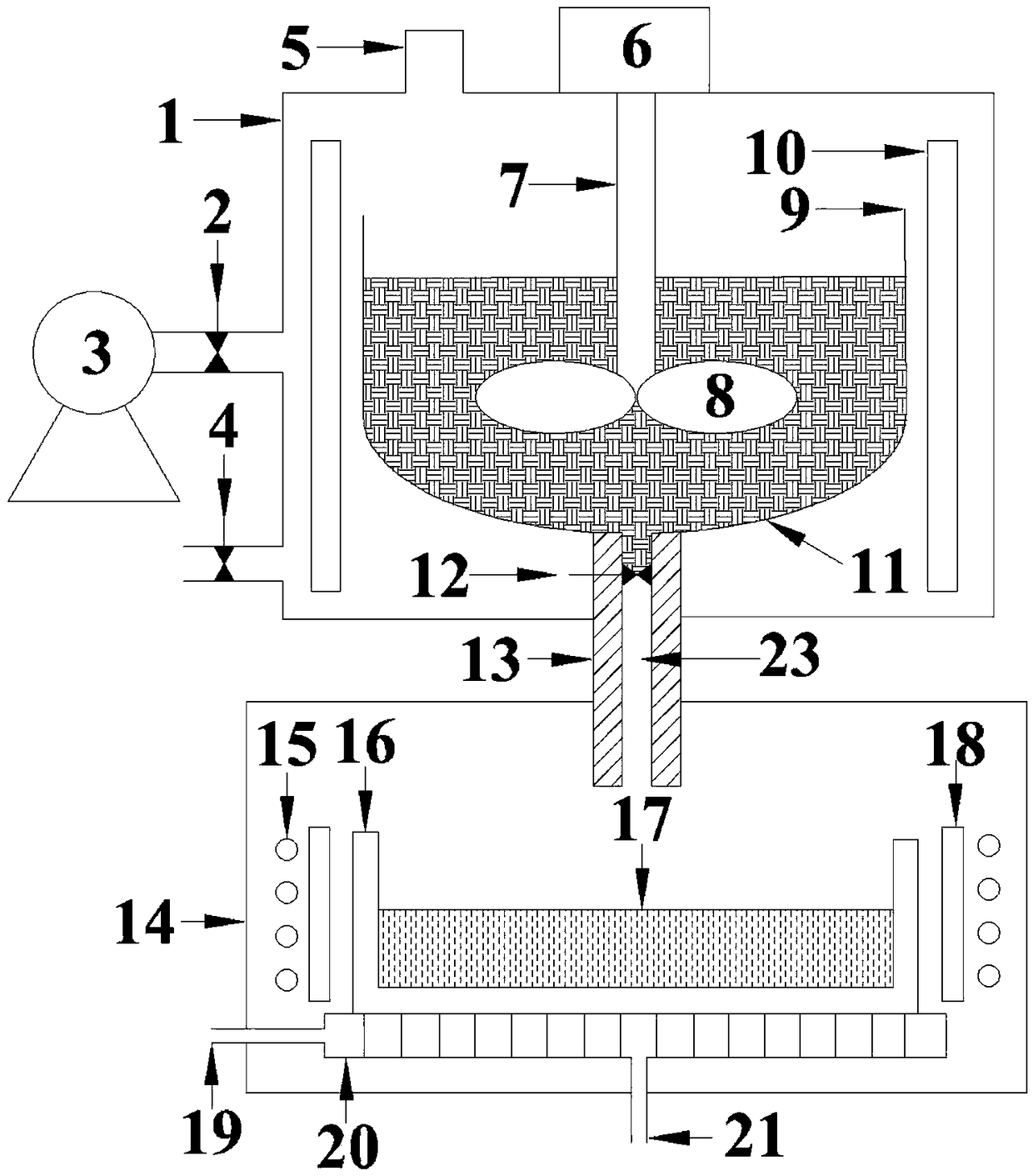

[0043] The steps of preparing aligned graphene magnesium-based alloy are as follows:

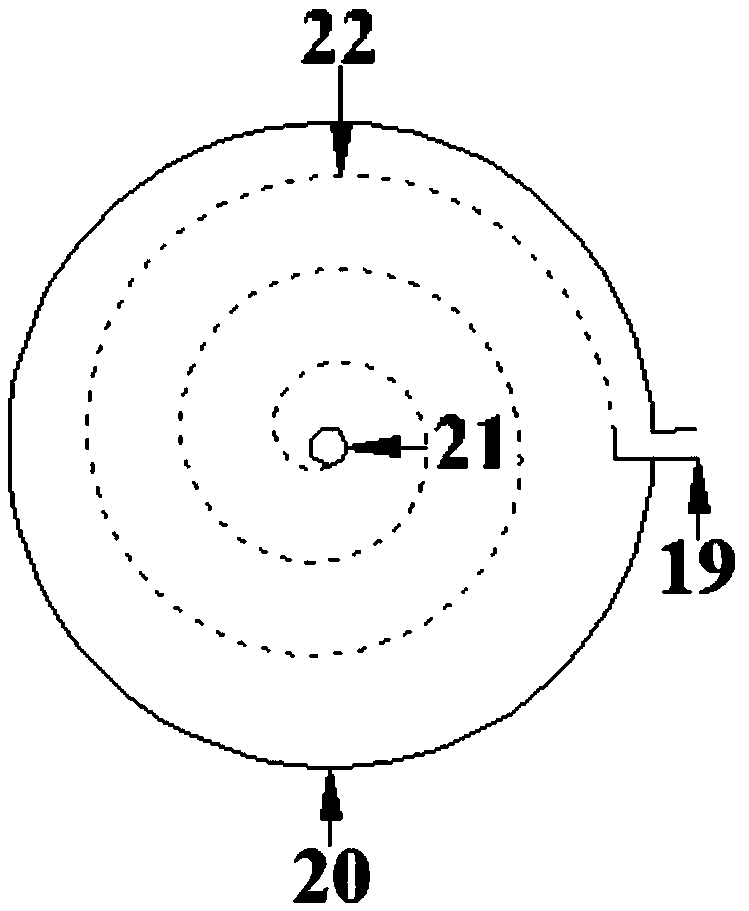

[0044] Vacuum the high-temperature melting furnace first, and then fill the high-temperature furnace with argon gas after vacuuming to 1.5 Pa, put pure magnesium into the melting crucible, then raise the temperature in the high-temperature melting furnace to 735°C, and keep it for 1 hour. Add pure metals Zn, Sn, Al, Sr, graphene nanosheets and Mg-15wt% Mn, Mg-10wt% Ca alloy compounds preheated to 550°C into the pure magnesium melt. The mass percentage of each component in the melting crucible is: Zn is 2.5wt%, Sn is 3.5wt%, Ca is 0.5wt%, Sr is 1.0wt%, Al is 0.5wt%, Mn is 0.2wt%, and graphene is 3.5wt%. wt%, and the balance is pure magnesium. Stir and smelt and remove slag for 1 hour, and then stand still for 15 to 30 minutes, adjust the temperature of the graphene alloy melt to 700°C; set the magnetic field in the crucible area of the casting furnace to 0.5T, and pour the evenly stirred a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com