Transparent electrical bushing

A kind of electrical casing, transparent technology, applied in the field of pipes, can solve the problems of unclear high-quality materials of lines, insufficient toughness of transparent line pipes, and time-consuming maintenance, etc., to achieve good circuit installation and inspection services, beautiful and generous colors , good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

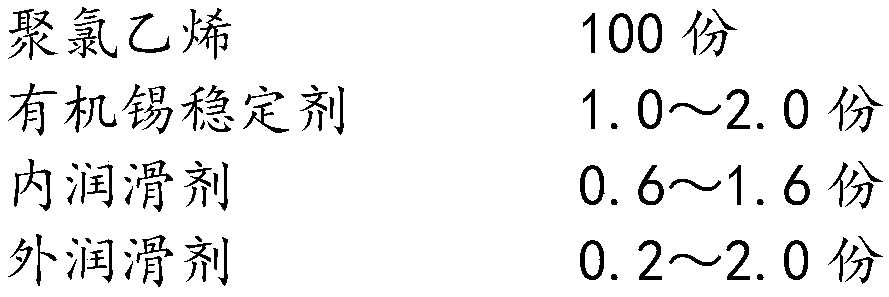

[0028] The transparent electrical sleeve provided in the present embodiment 1 is made of the following components in parts by weight:

[0029]

[0030] The transparent electrical casing is made by a twin-screw extruder through raw and auxiliary material ratio-high-speed thermal mixing-twin-screw extrusion-sizing-cooling-drawing-cutting.

Embodiment 2

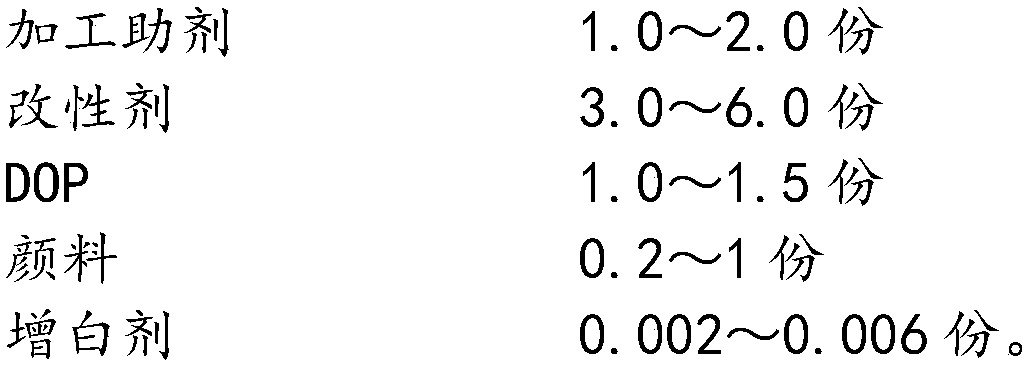

[0032] The transparent electrical sleeve provided in this embodiment 2 is made from the following components in parts by weight:

[0033]

[0034] The transparent electrical casing is made by a twin-screw extruder through raw and auxiliary material ratio-high-speed thermal mixing-twin-screw extrusion-sizing-cooling-drawing-cutting.

Embodiment 3

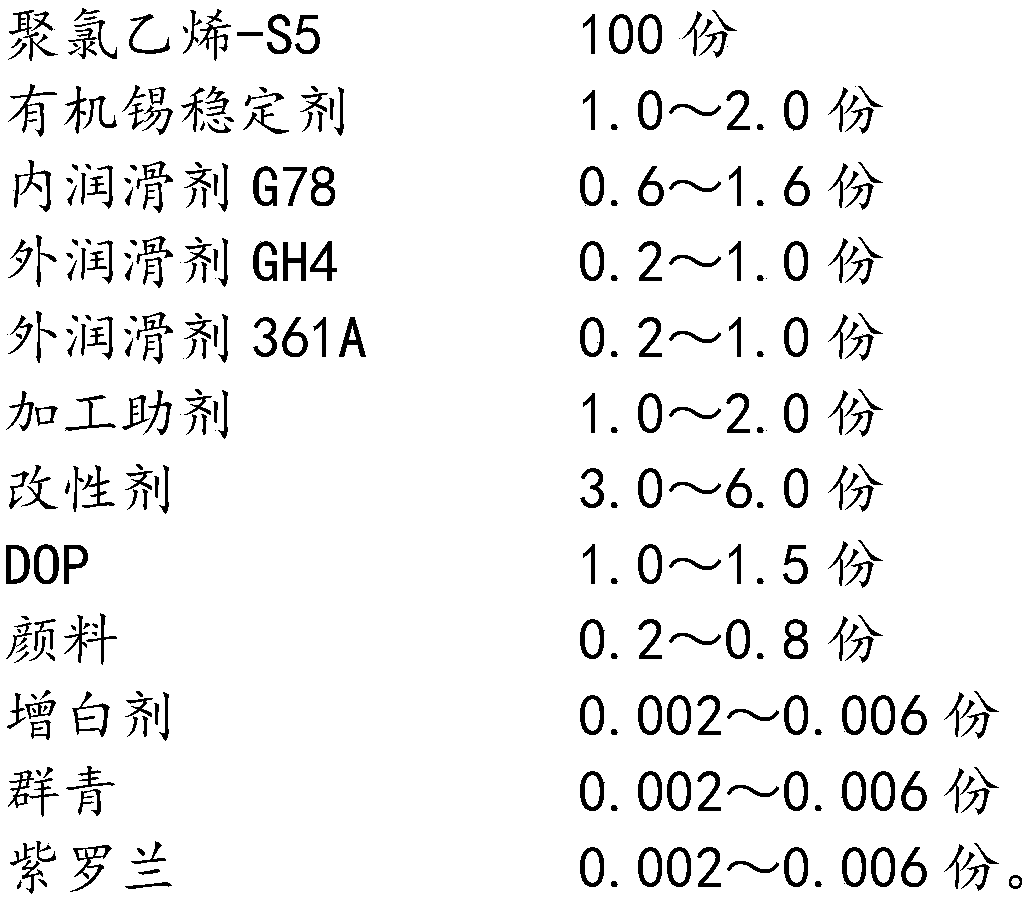

[0036] The transparent electrical sleeve provided in this embodiment 3 is made from the following components in parts by weight:

[0037]

[0038] The transparent electrical casing is made by a twin-screw extruder through raw and auxiliary material ratio-high-speed thermal mixing-twin-screw extrusion-sizing-cooling-drawing-cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com