Production system and production technology for 99-grade pentaerythritol

A pentaerythritol and production process technology, applied in the field of pentaerythritol production technology, can solve the problems of high labor intensity and personnel intensity, reduced pentaerythritol production efficiency, reduced pentaerythritol purity, etc., achieves low labor intensity and personnel intensity, and eliminates moisture The effect of exceeding the standard and material condensation, improving the purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

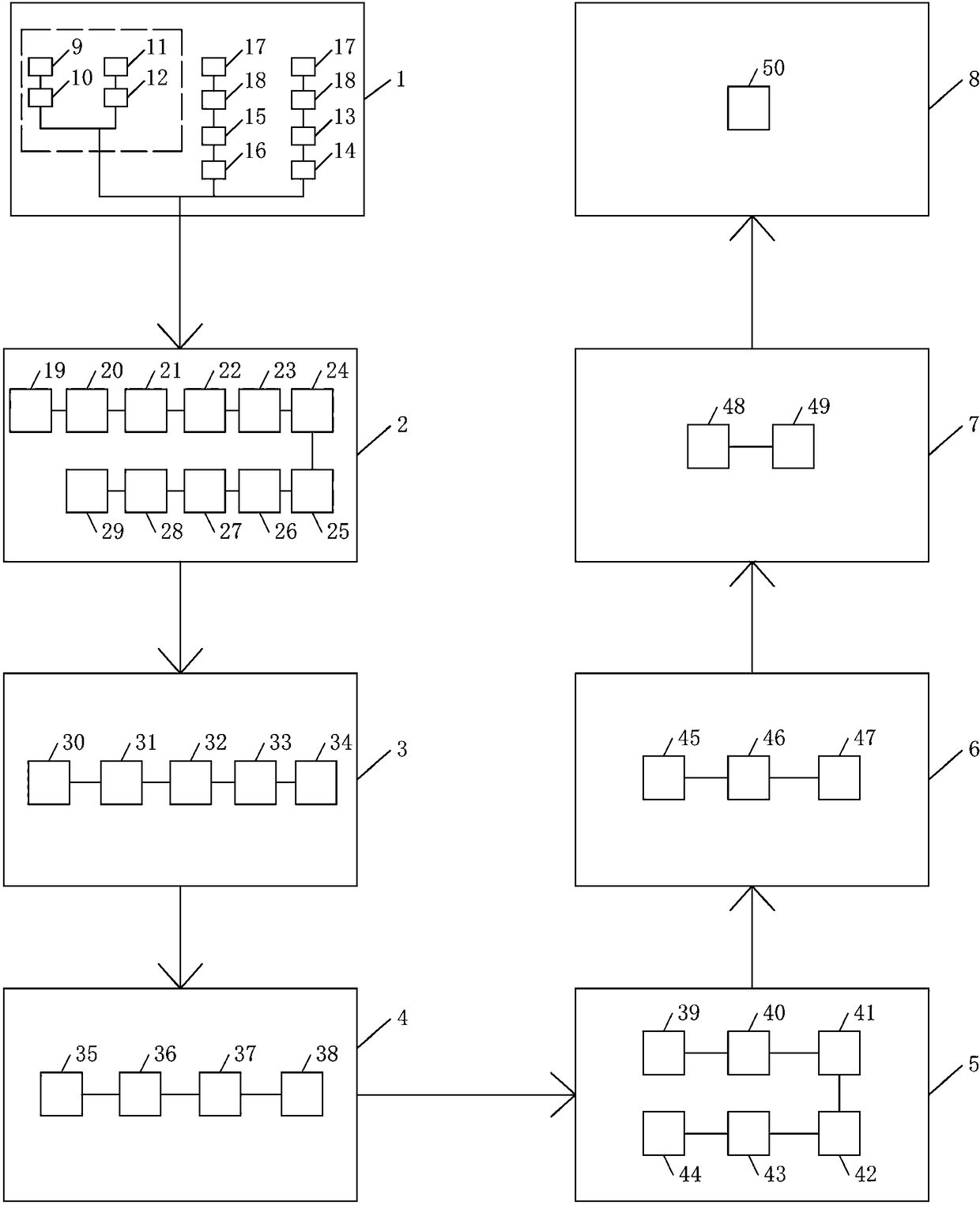

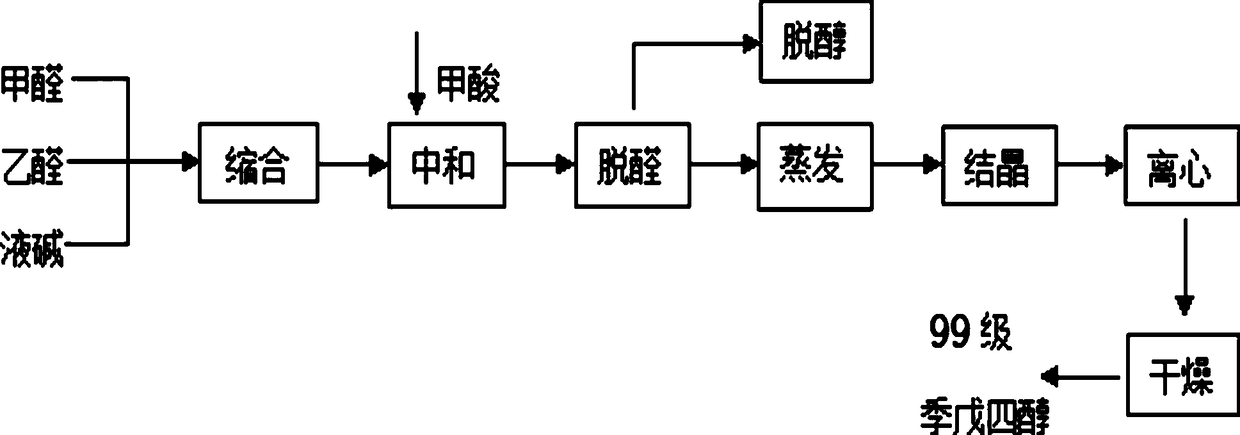

[0032] Embodiment 1: a kind of production technique of 99 grades of pentaerythritol, this production technique comprises the steps:

[0033] S1: Formaldehyde, acetaldehyde and liquid caustic soda are put into the four-stage series tank reactor in the reaction unit 2 through the feeding unit 1 according to the molar ratio of 9.5:1:1.15 for condensation reaction, and the mixed components are obtained; Among them, the temperatures of the first-stage reactor 19, the second-stage reactor 21, the third-stage reactor 23 and the fourth-stage reactor 25 are respectively controlled at 22°C, 28°C, 32°C, and 38°C; the final mixed components flow into the neutralization kettle And use formic acid to adjust to a suitable pH to obtain a condensation liquid; the feeding ratio and temperature are automatically controlled by the DCS system;

[0034] S2: When preheating the condensation liquid, use alcohol-containing dilute formaldehyde as the heat source, then transport the preheated condensati...

Embodiment 2

[0040] Embodiment 2: a kind of production technique of 99 grades of pentaerythritol, this production technique comprises the steps:

[0041] S1: Formaldehyde, acetaldehyde and liquid caustic soda are put into the four-stage series tank reactor in the reaction unit 2 through the feeding unit 1 according to the molar ratio of 9.5:1:1.15 for condensation reaction, and the mixed components are obtained; Among them, the temperatures of the first-stage reactor 19, the second-stage reactor 21, the third-stage reactor 23, and the fourth-stage reactor 25 are respectively controlled at 25°C, 30°C, 35°C, and 40°C; the final mixed components flow into the neutralization kettle And use formic acid to adjust to a suitable pH to obtain a condensation liquid; the feeding ratio and temperature are automatically controlled by the DCS system;

[0042] S2: When the condensation liquid is preheated, alcohol-containing dilute formaldehyde is used as a heat source, and then the preheated condensatio...

Embodiment 3

[0048] Embodiment 3: a kind of production technique of 99 grades of pentaerythritol, this production technique comprises the steps:

[0049] S1: Formaldehyde, acetaldehyde and liquid caustic soda are put into the four-stage series tank reactor in the reaction unit 2 through the feeding unit 1 according to the molar ratio of 9.5:1:1.15 for condensation reaction, and the mixed components are obtained; Among them, the temperatures of the first-stage reactor 19, the second-stage reactor 21, the third-stage reactor 23, and the fourth-stage reactor 25 are respectively controlled at 26°C, 31°C, 36°C, and 41°C; the final mixed components flow into the neutralization kettle And use formic acid to adjust to a suitable pH to obtain a condensation liquid; the feeding ratio and temperature are automatically controlled by the DCS system;

[0050] S2: When preheating the condensation liquid, use alcohol-containing dilute formaldehyde as the heat source, then transport the preheated condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com