Control method and device for bidirectional rotary printing

A printing control and printing position technology, applied in the printing field, can solve the problems of left and right misalignment, blurred characters, indistinctness, etc., to achieve the effect of ensuring efficiency and improving printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

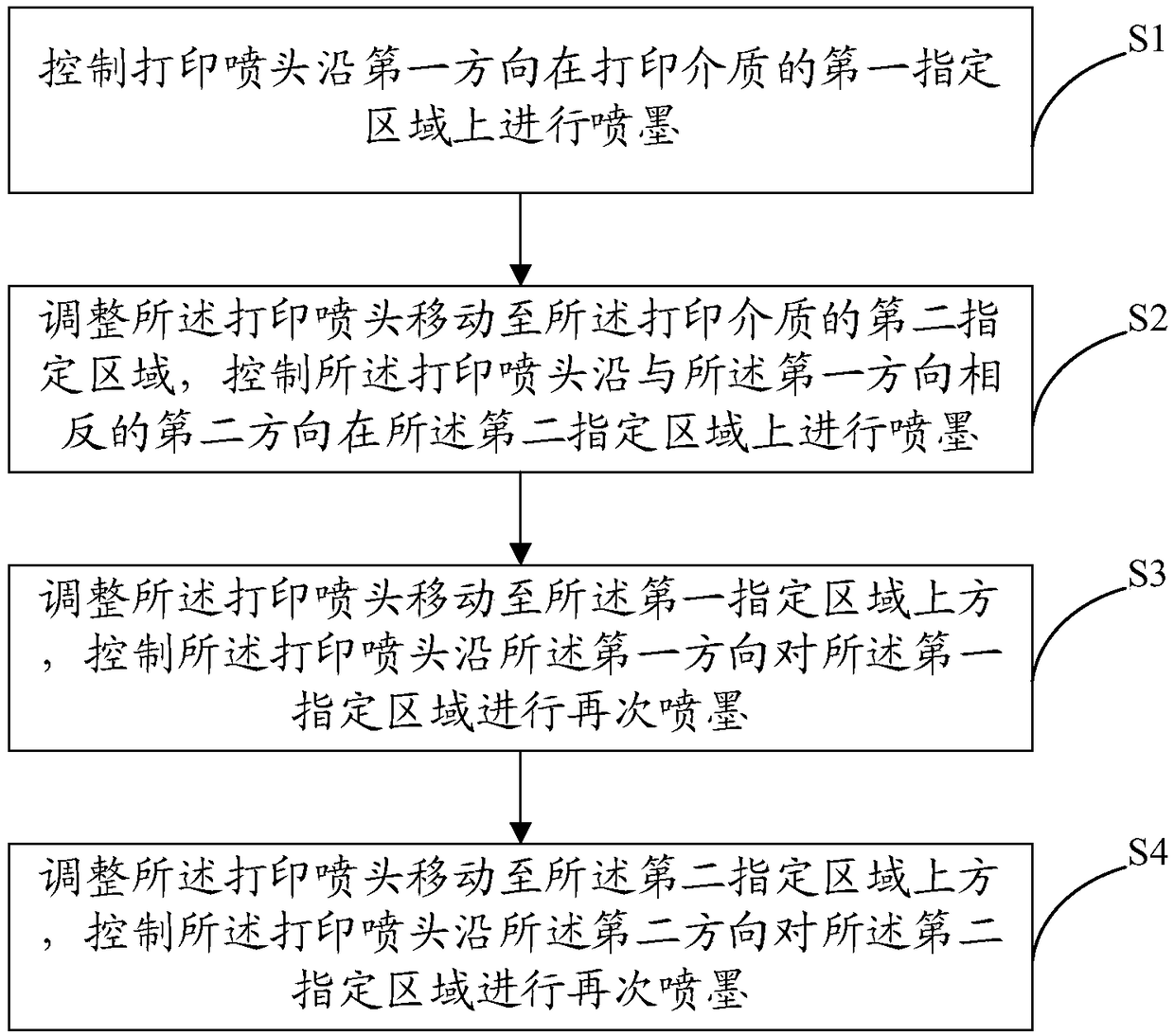

Embodiment 1

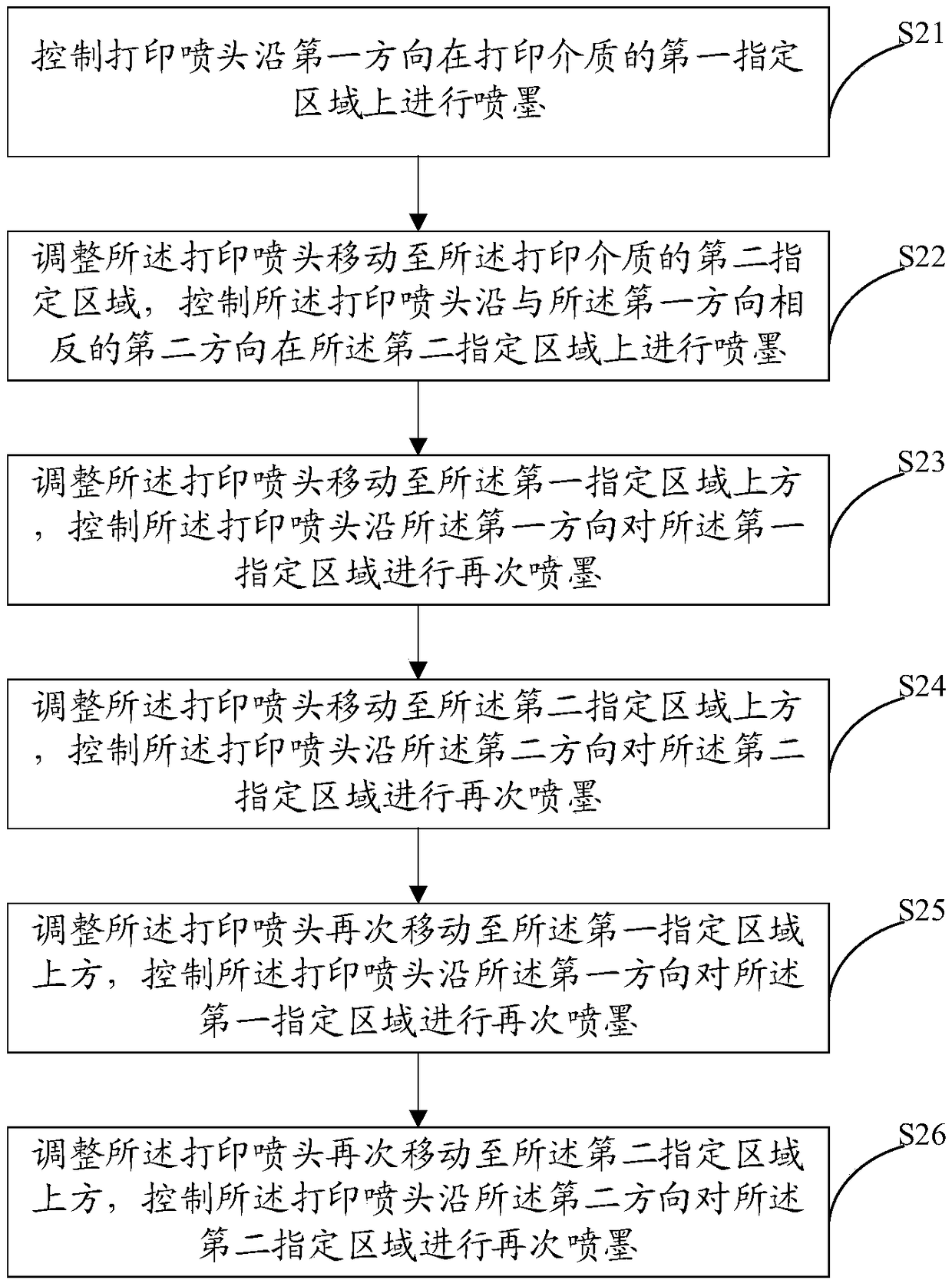

[0061] In this embodiment, each printing unit needs to cover 3 times, that is, 3pass printing, and the width of the first designated area perpendicular to the first direction is x 1 , the width of the print nozzle perpendicular to the first direction is x 2 , then x 1 =x 2 , the width of the pattern to be printed is twice the width of the nozzle along the first direction perpendicular to the first direction, that is, the image to be printed includes a first designated area and a second designated area, and the first designated area and the second designated area areas are adjacent, and the first specified area does not overlap with the second specified area, then refer to figure 2 , the specific printing steps of this embodiment are:

[0062] S21. Control the printing nozzle to spray ink on the first designated area of the printing medium along the first direction;

[0063] S22. Adjust the print head to move to a second designated area of the printing medium, and cont...

Embodiment 2

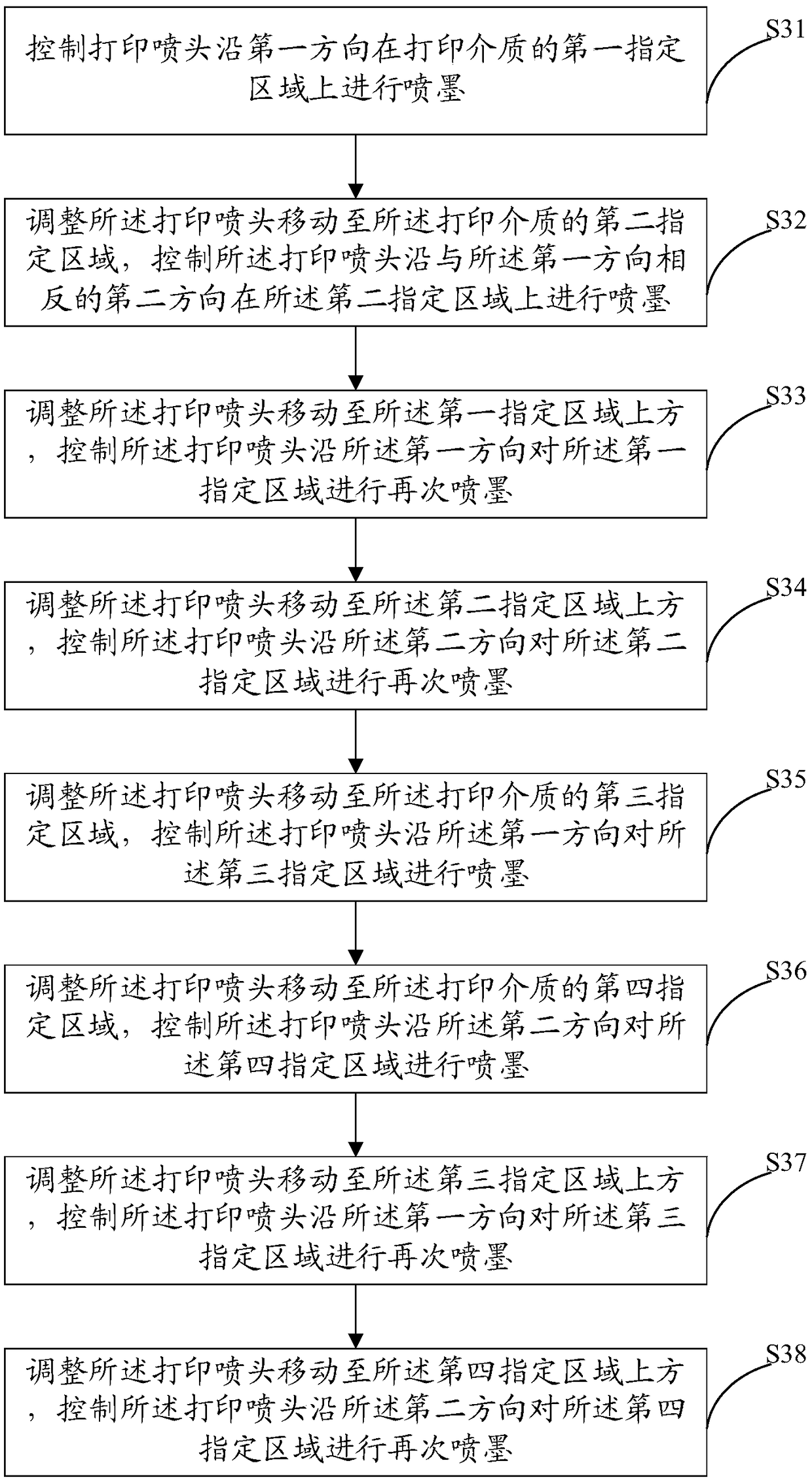

[0071] In this embodiment, each printing unit needs to cover 2 times, that is, 2pass printing, and the width of the first designated area perpendicular to the first direction is x 1 , the width of the print nozzle perpendicular to the first direction is x 2 , then x 1 =x 2 , the width of the pattern to be printed is 4 times the width of the nozzle along the vertical direction, that is, the image to be printed includes a first specified area, a second specified area, a third area and a fourth area. then see image 3 , the specific printing steps of this embodiment are:

[0072] S31. Control the printing nozzle to spray ink on the first designated area of the printing medium along the first direction;

[0073] S32. Adjust the printing head to move to a second designated area of the printing medium, and control the printing head to eject ink on the second designated area along a second direction opposite to the first direction;

[0074] S33. Adjust the printing head to m...

Embodiment 3

[0082] In this embodiment, each printing unit needs to cover 2 times, that is, 2pass printing, and the width of the first designated area perpendicular to the first direction is x 1 , the width of the print nozzle perpendicular to the first direction is x 2 , then x 1 =x 2 , the width of the pattern to be printed is three times the width of the nozzle along the vertical direction, that is, the image to be printed includes a first designated area, a second designated area and a fifth area. then see Figure 5 , the specific printing steps of this embodiment are:

[0083] S51. Control the printing nozzle to spray ink on the first designated area of the printing medium along the first direction;

[0084] S52. Adjust the print head to move to a second designated area of the printing medium, and control the print head to eject ink on the second designated area along a second direction opposite to the first direction;

[0085] S53. Adjust the printing head to move above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com