Automatic-contour-tracking polishing device

A polishing device and automatic tracking technology, used in grinding drive devices, grinding/polishing equipment, machine tools with surface polishing, etc., can solve the problems of low polishing accuracy, incomplete polishing, poor polishing effect, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

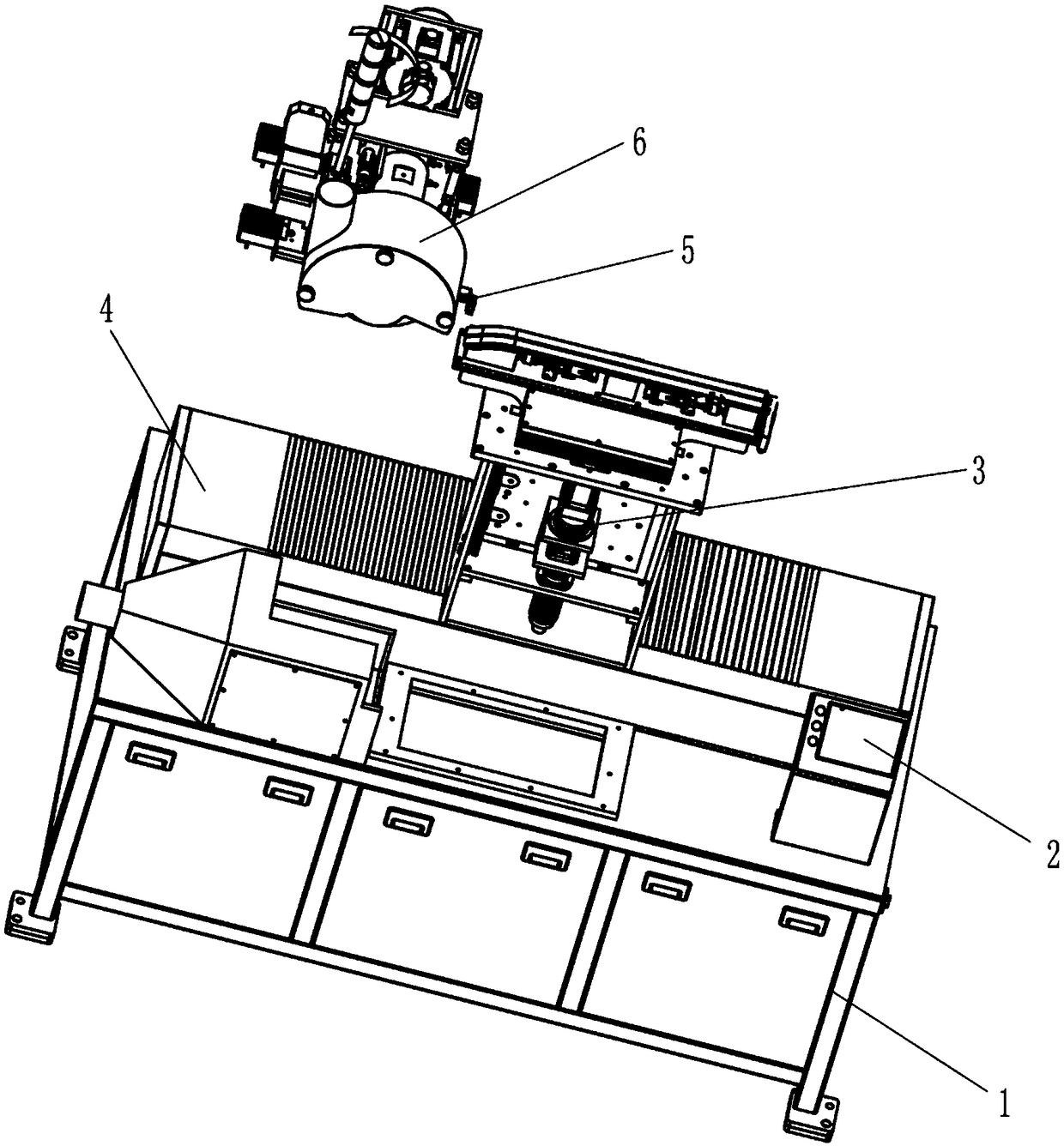

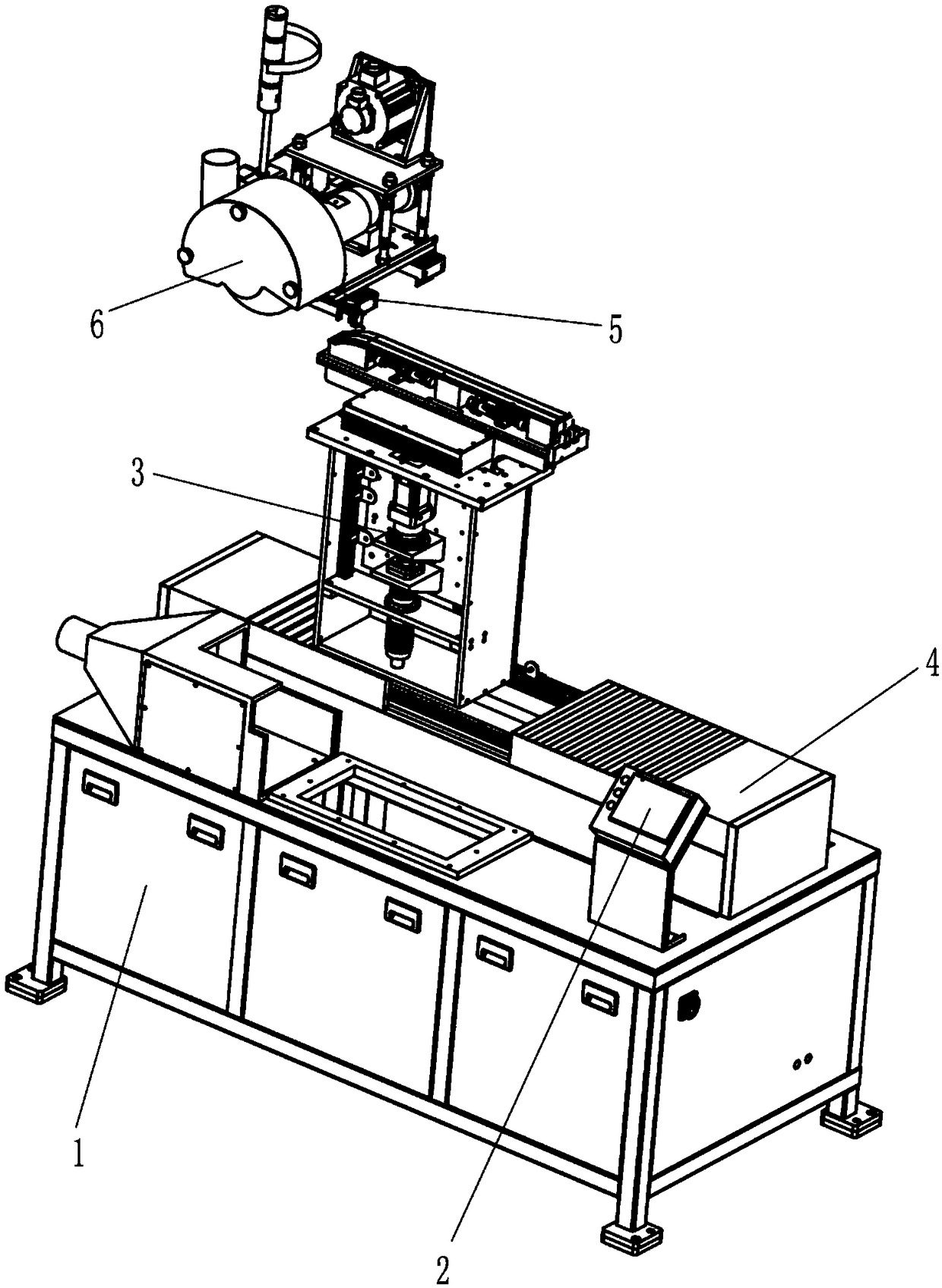

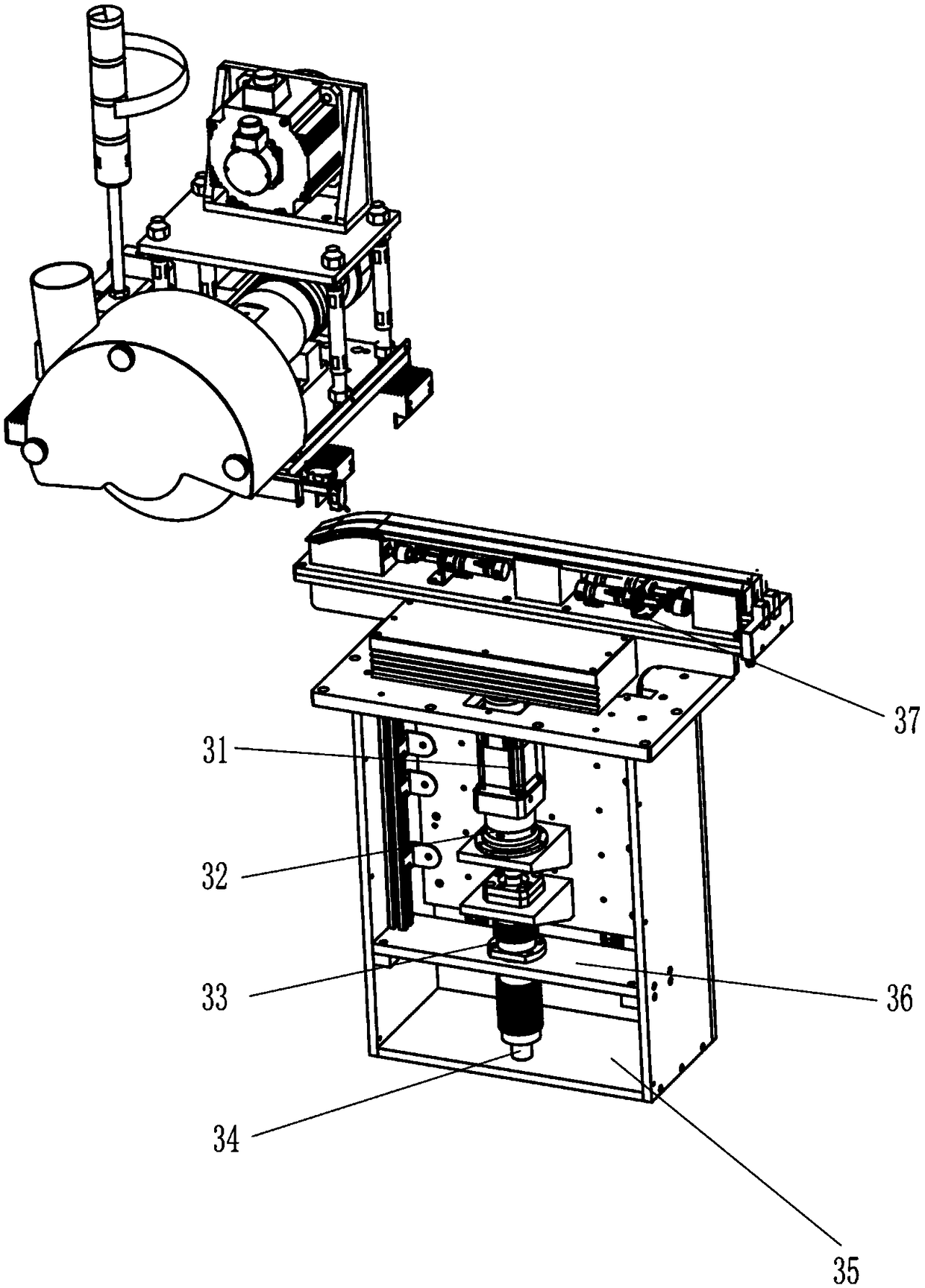

[0026] A polishing device that automatically follows the contour, such as Figure 1-2 As shown, it includes a frame 1, a control touch screen 2, an up and down movement mechanism 3, a reciprocating mechanism 4, a laser sensor 5 and a polishing mechanism 6; the reciprocating mechanism 4 is fixedly installed on the frame 1; The bottom of the mechanism 6 is connected with the moving end of the reciprocating mechanism 4, and the polishing mechanism 6 can reciprocate along the motion track of the reciprocating mechanism 4; the bottom of the moving mechanism 3 is installed on the frame 1, and it moves The end is used to clamp the workpiece to be processed, and the vertical movement mechanism 3 can adjust the height position of the workpiece; the laser sensor 5 is fixedly installed on the front end of the polishing mechanism 6; the control touch screen 2 is installed on the frame 1.

[0027] The control touch screen 2 is electrically connected with the CNC PLC system to transmit inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com