Steel pipe batched rust-removal device

A batch, steel pipe technology, used in metal processing equipment, grinding/polishing equipment, grinders, etc., can solve problems such as poor rust removal effect and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

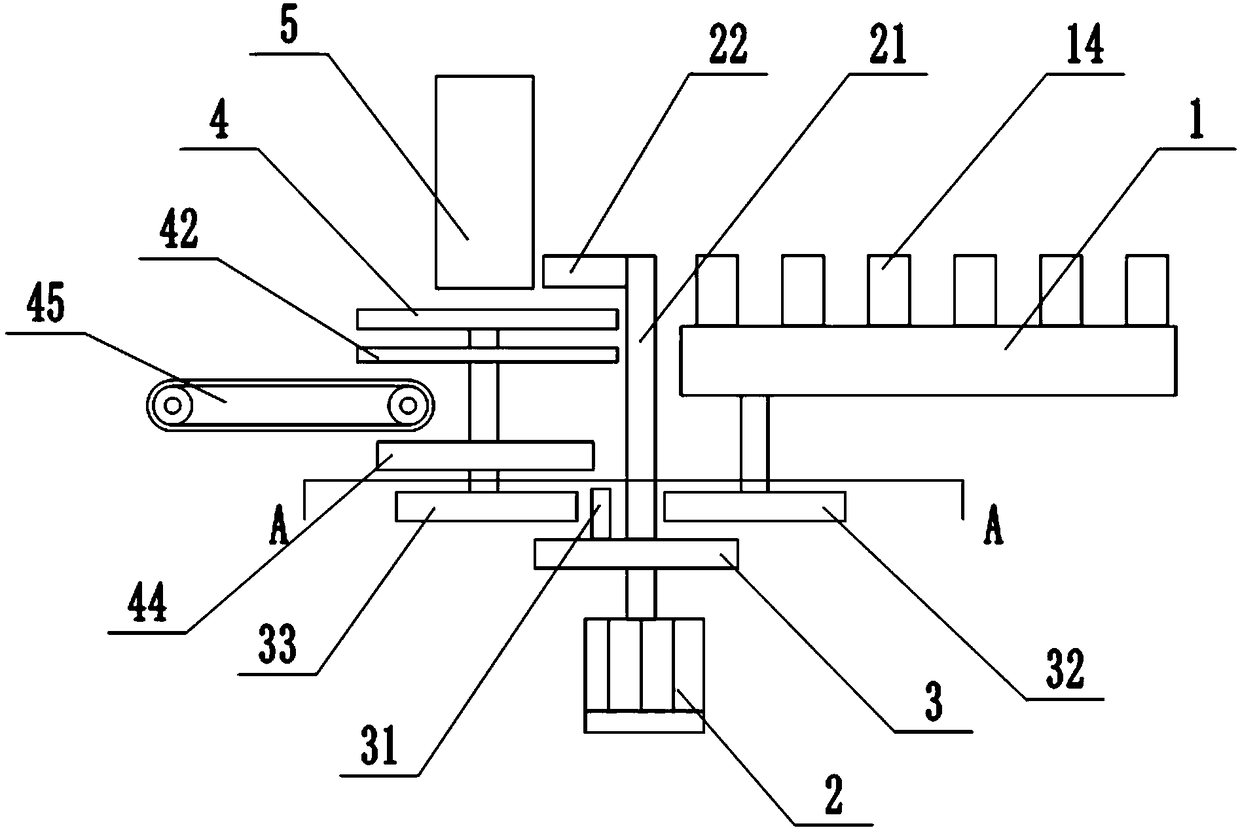

[0020] The reference signs in the drawings of the description include: conveying mechanism 1, endless conveyor belt 11, driving wheel 12, driven wheel 13, steel pipe 14, first motor 2, vertical rod 21, toggle rod 22, turntable 3, pin rod 31 , the second sheave 32, the first sheave 33, the round platform 4, the arc mouth 41, the ring tray 42, the opening 43, the ring recovery tank 44, the horizontal conveyor belt 45, the derusting mechanism 5, the second motor 51, the first gear 52. Second gear 53, ring gear 54, rotating shaft 6, first brush roller 61, cylindrical cam 7, curved chute 71, slider 72, L-shaped rod 73, fixed rod 74, second brush roller 75 , liquid storage cylinder 8, air inlet 81, liquid outlet 82, liquid outlet pipe 83, slide bar 9, piston 91, slide plate 92, spring 93.

[0021] The embodiment is basically as attached Figures 1 to 6 Shown: a steel pipe bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com