Air purifying membrane and preparation method thereof

An air purification and sodium chloride technology, applied in the field of air purification, can solve problems affecting performance and service life, achieve long-term negative ion release function, improve filtration efficiency, and stabilize filter materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

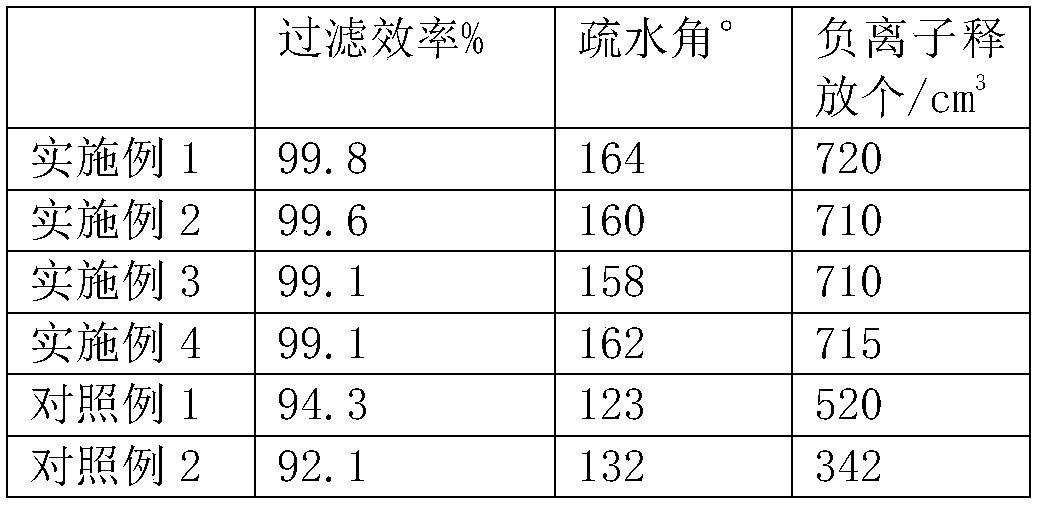

Examples

Embodiment 1

[0017] The air purification film comprises the following raw materials in parts by weight: 35 parts of sodium chloride, 25 parts of polytetrafluoroethylene, 60 parts of zinc naphthenate, 15 parts of manganese oxide, 70 parts of graphite powder, 170 parts of chlorinated polyethylene, hard 60 parts of calcium fatty acid, 45 parts of methyl vinyl phenyl silicone rubber, 6 parts of polyethylene wax and 79 parts of water.

[0018] The preparation method of the air purification membrane comprises the following steps: adding sodium chloride, polytetrafluoroethylene, and zinc naphthenate into water, and stirring evenly; adding manganese oxide, graphite powder, chlorinated polyethylene, calcium stearate, methyl Vinyl phenyl silicone rubber and polyethylene wax, after mixing, filter out the solution; make the filter residue into a melt, extrude, the extrusion temperature is 140-180 ℃, blow molding into a film, the screw speed is 115r / min.

Embodiment 2

[0020] The air purification membrane comprises the following raw materials in parts by weight: 30 parts of sodium chloride, 20 parts of polytetrafluoroethylene, 40 parts of zinc naphthenate, 10 parts of manganese oxide, 60 parts of graphite powder, 160 parts of chlorinated polyethylene, hard 40 parts of calcium fatty acid, 40 parts of methyl vinyl phenyl silicone rubber, 3 parts of polyethylene wax and 78 parts of water.

[0021] The preparation method of the air purification membrane comprises the following steps: adding sodium chloride, polytetrafluoroethylene, and zinc naphthenate into water, and stirring evenly; adding manganese oxide, graphite powder, chlorinated polyethylene, calcium stearate, methyl Vinyl phenyl silicone rubber and polyethylene wax, after mixing, filter out the solution; make the filter residue into a melt, extrude, the extrusion temperature is 140-180 ℃, blow molding into a film, the screw speed is 120r / min.

Embodiment 3

[0023] The air purification film comprises the following raw materials in parts by weight: 40 parts of sodium chloride, 30 parts of polytetrafluoroethylene, 80 parts of zinc naphthenate, 20 parts of manganese oxide, 90 parts of graphite powder, 180 parts of chlorinated polyethylene, hard 80 parts of calcium fatty acid, 50 parts of methyl vinyl phenyl silicone rubber, 8 parts of polyethylene wax and 80 parts of water.

[0024] The preparation method of the air purification membrane comprises the following steps: adding sodium chloride, polytetrafluoroethylene, and zinc naphthenate into water, and stirring evenly; adding manganese oxide, graphite powder, chlorinated polyethylene, calcium stearate, methyl Vinyl phenyl silicone rubber and polyethylene wax, after mixing, filter out the solution; make the filter residue into a melt, extrude, the extrusion temperature is 140-180 ℃, blow molding into a film, the screw speed is 100r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com