Dust removal pipeline for water curtain net

A water curtain dust collector and pipeline technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve problems such as the reduction of pipeline dust removal efficiency, prevent dust adhesion, improve dust removal efficiency, and avoid blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

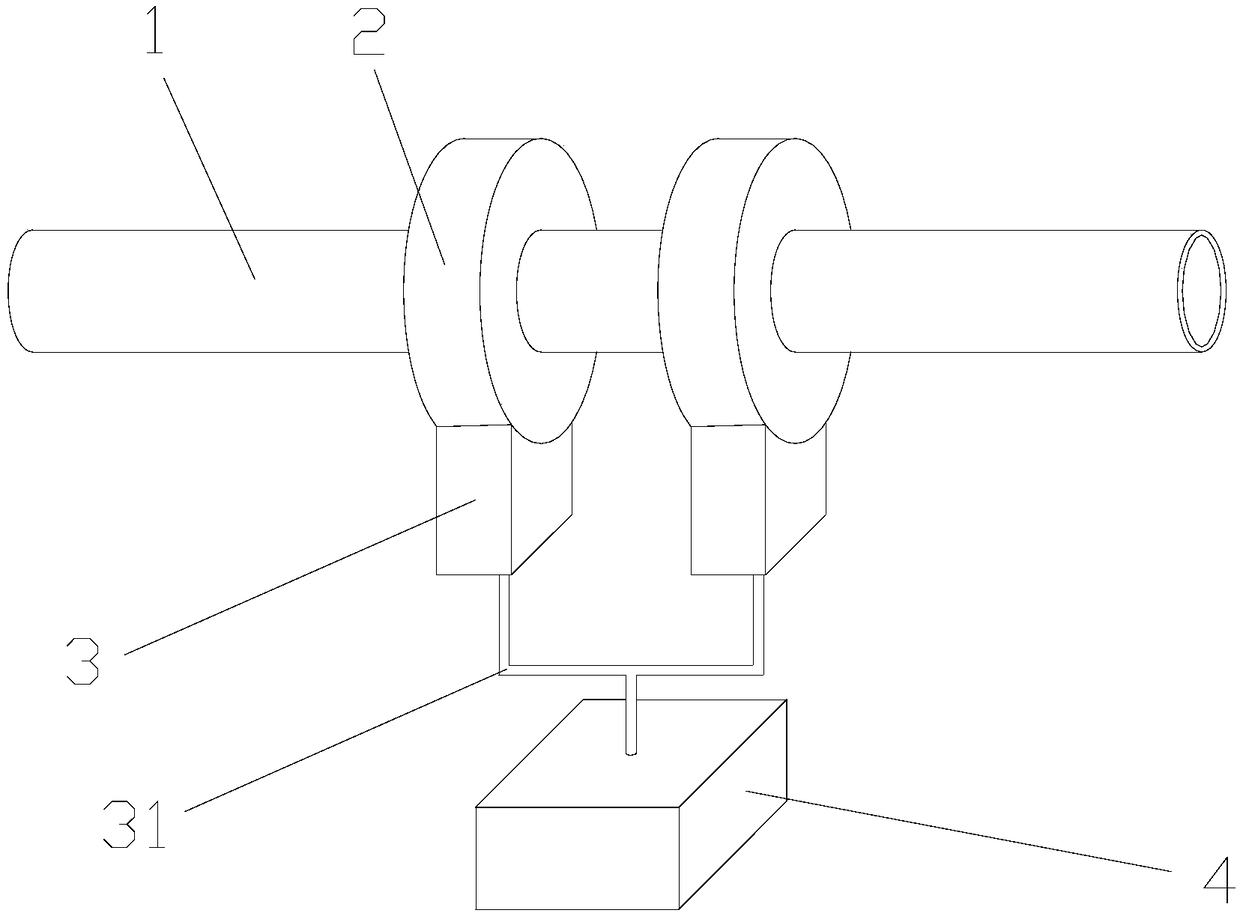

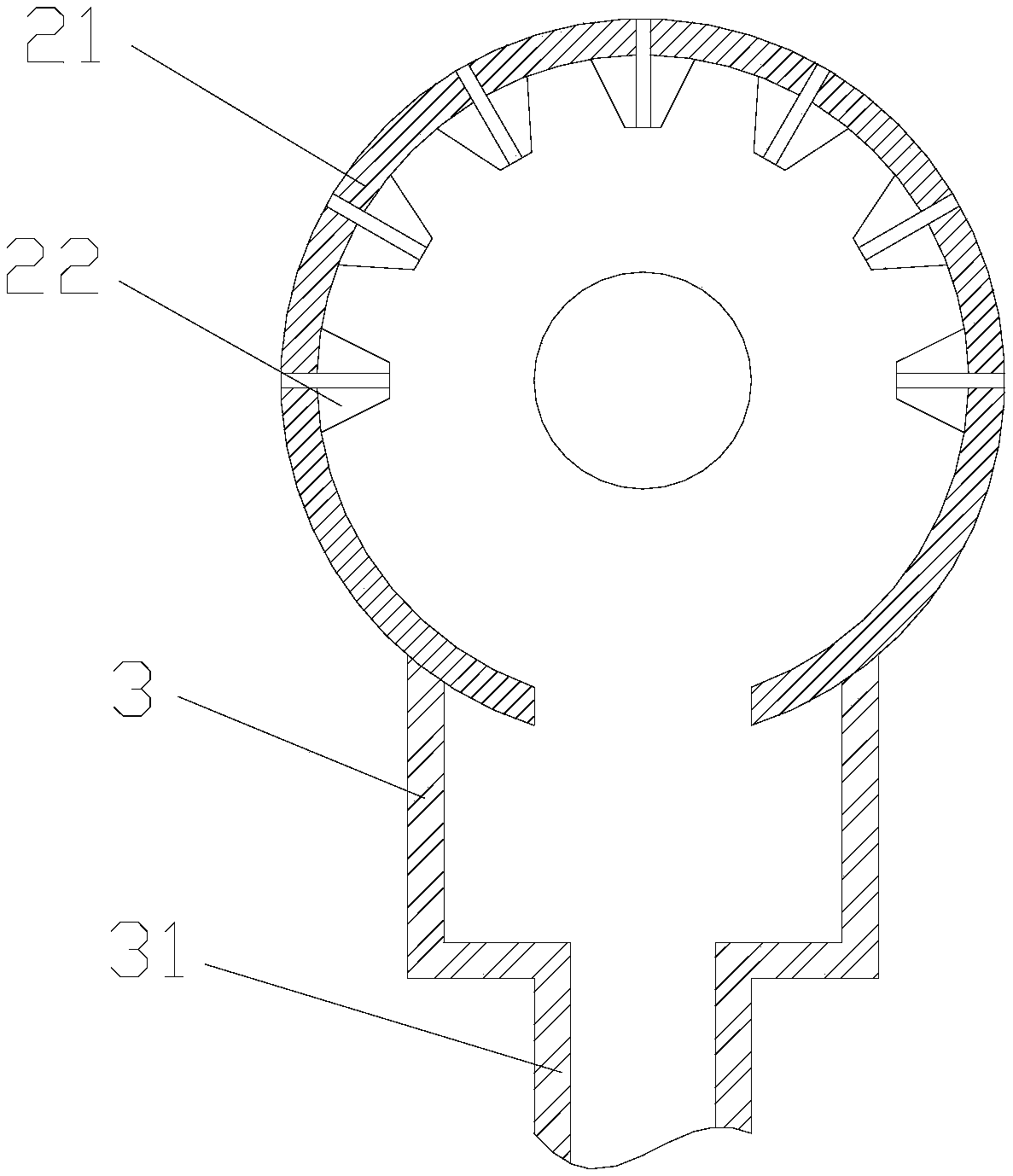

[0080] In this embodiment, a high-pressure pump with a flow rate of 50 tons per hour is used to remove dust from the water curtain net of a 100-ton boiler. Two layers of water curtain dust collectors 2 are installed in the conveying pipeline 1, and seven high-pressure Nozzles 22, wherein the flow rate of each high-pressure nozzle 22 is 14L / S,

[0081] In this embodiment, the pressure of the flue gas is set between 200-600kpa, and the water pressure of the high-pressure nozzle is set at 700kpa to prevent the sewage from being carried away by the flue gas.

[0082] The embodiment of the water curtain net dedusting pipeline described in this embodiment is the same as the above embodiment.

[0083] After running through the pipeline, it can be obtained that the removal rate of the dust in the pipeline flue gas reaches 97.6%, and the pipeline of the present invention can efficiently remove the flue gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com