Fire-fighting water system for super-high-rise building construction stage and construction method

A technology of building construction and construction method, applied in fire rescue and other directions, can solve the problems of pipeline and electromechanical arrangement and construction impact, high construction cost, and difficulty in dismantling, so as to reduce construction tasks and demolition tasks, and reduce construction workload. , the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

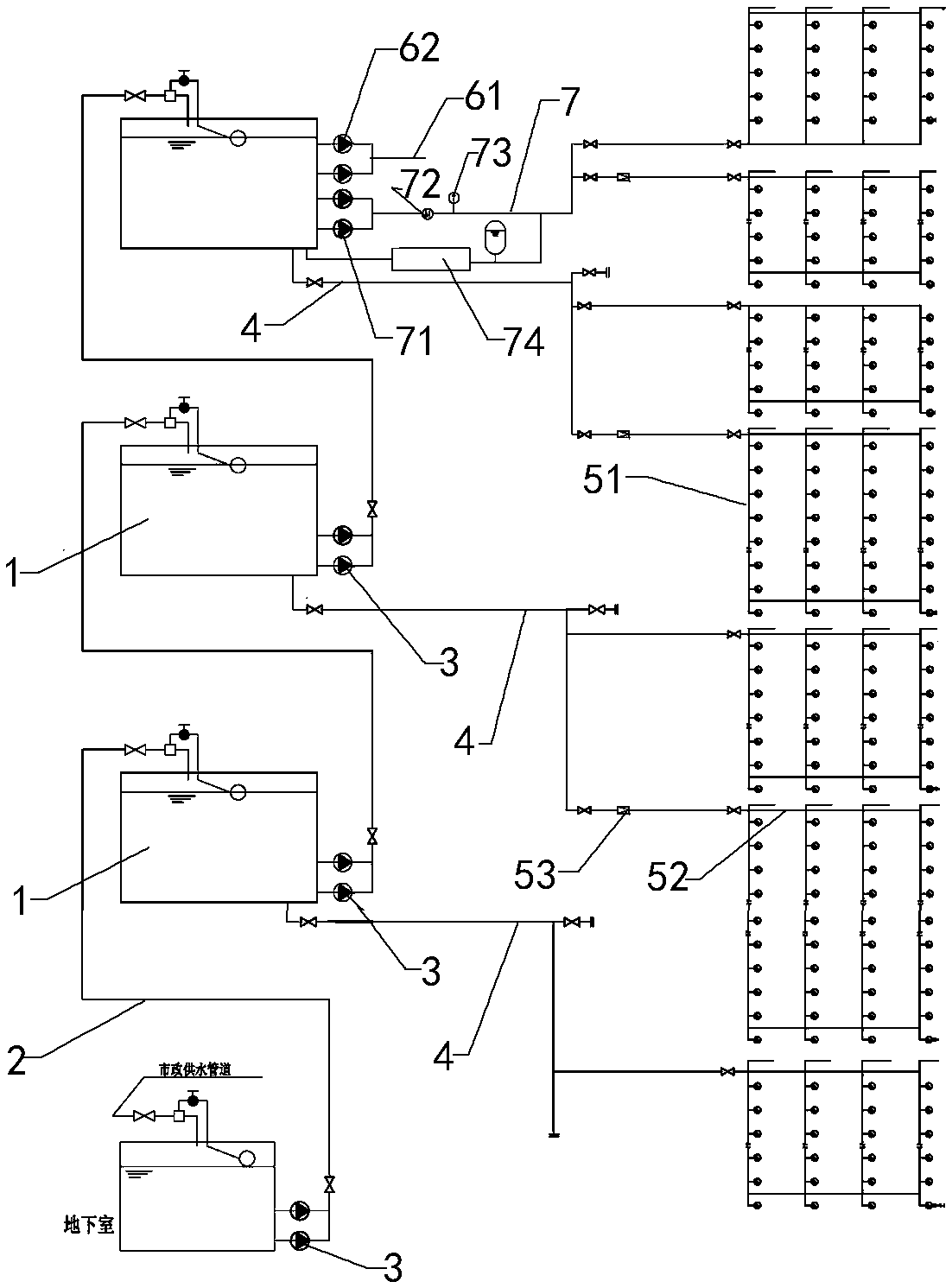

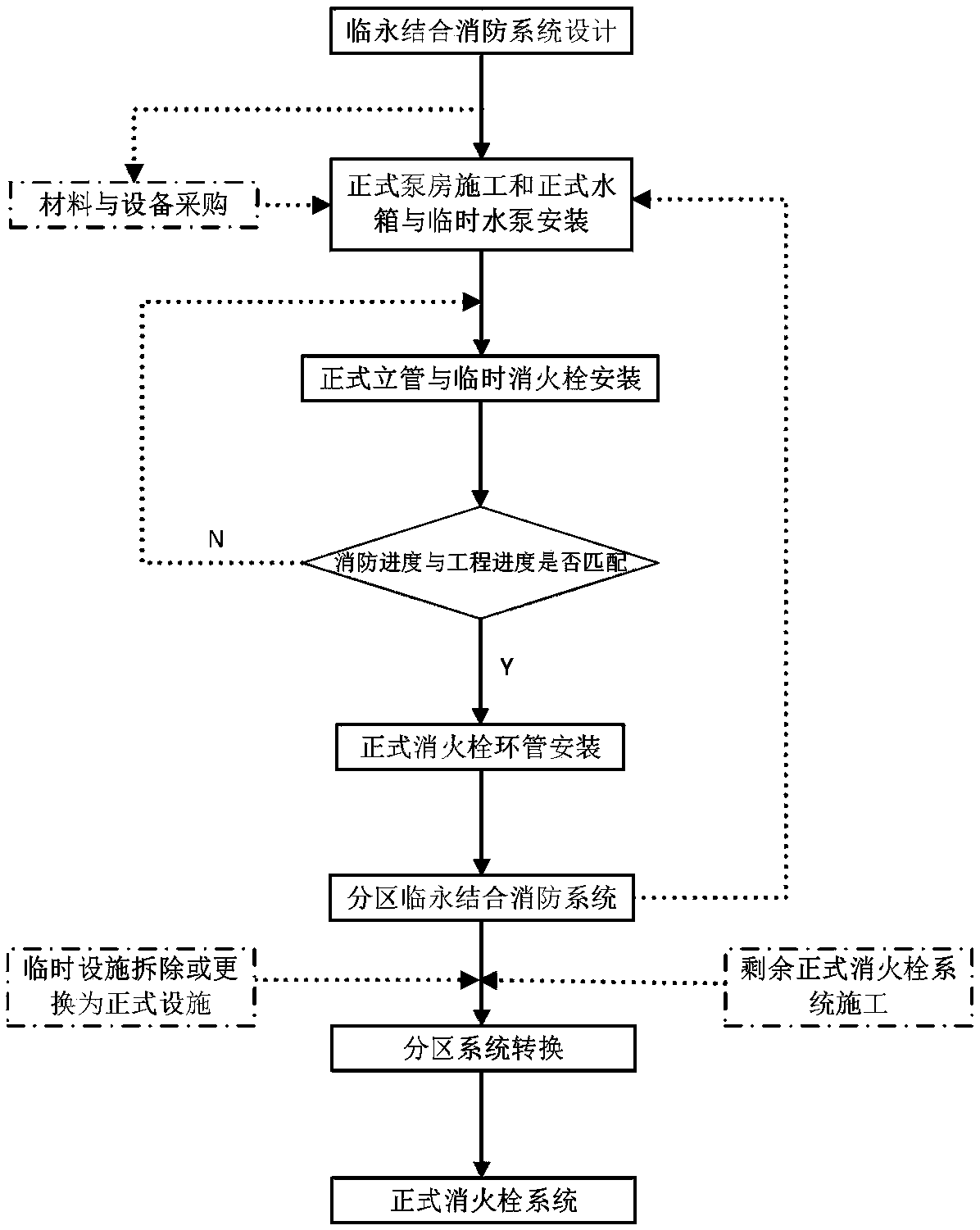

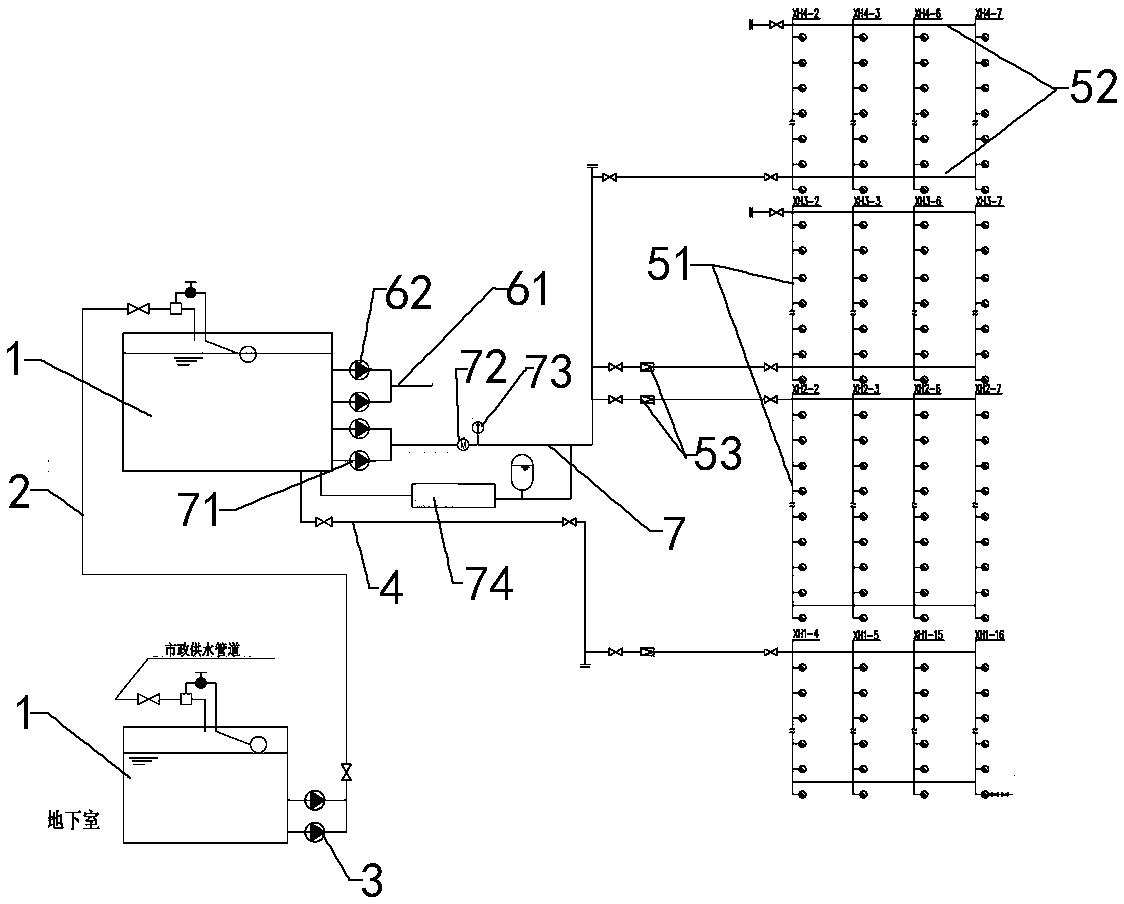

[0042] Such as figure 1 Shown, the present invention is used for the fire-fighting water system of super high-rise building construction phase and comprises the fire-fighting transfer water tank 1 that building is used formally, temporary fire-fighting water supply pipe network, the temporary water supply that connects fire-fighting transfer water tank 1 and temporary fire-fighting water supply pipe network Pipeline 4, and a temporary fire hydrant connected to the outlet of the temporary fire water supply network.

[0043]A fire transfer water tank 1 is installed every 100-140m in a super high-rise building. The transfer pipe 2 is connected with the fire protection transfer pipe 2. The transfer pipe 2 is a steel pipe with a nominal diameter of not less than 250mm. The transfer pipe 2 is provided with a temporary transfer pump 3. The lift of the temporary transfer pump 3 is higher than that of the official fire protection transfer pump 9. Each fire-fighting transfer water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com