High-frequency thawing device and high-frequency thawing method

A high-frequency, high-frequency generator technology, applied in the field of high-frequency applications, can solve the problems of reduced commodity value, frozen food can not be thawed uniformly, dielectric loss and high conductivity, to achieve uniform thawing speed, reduce edge effects, The effect of uniform heating electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

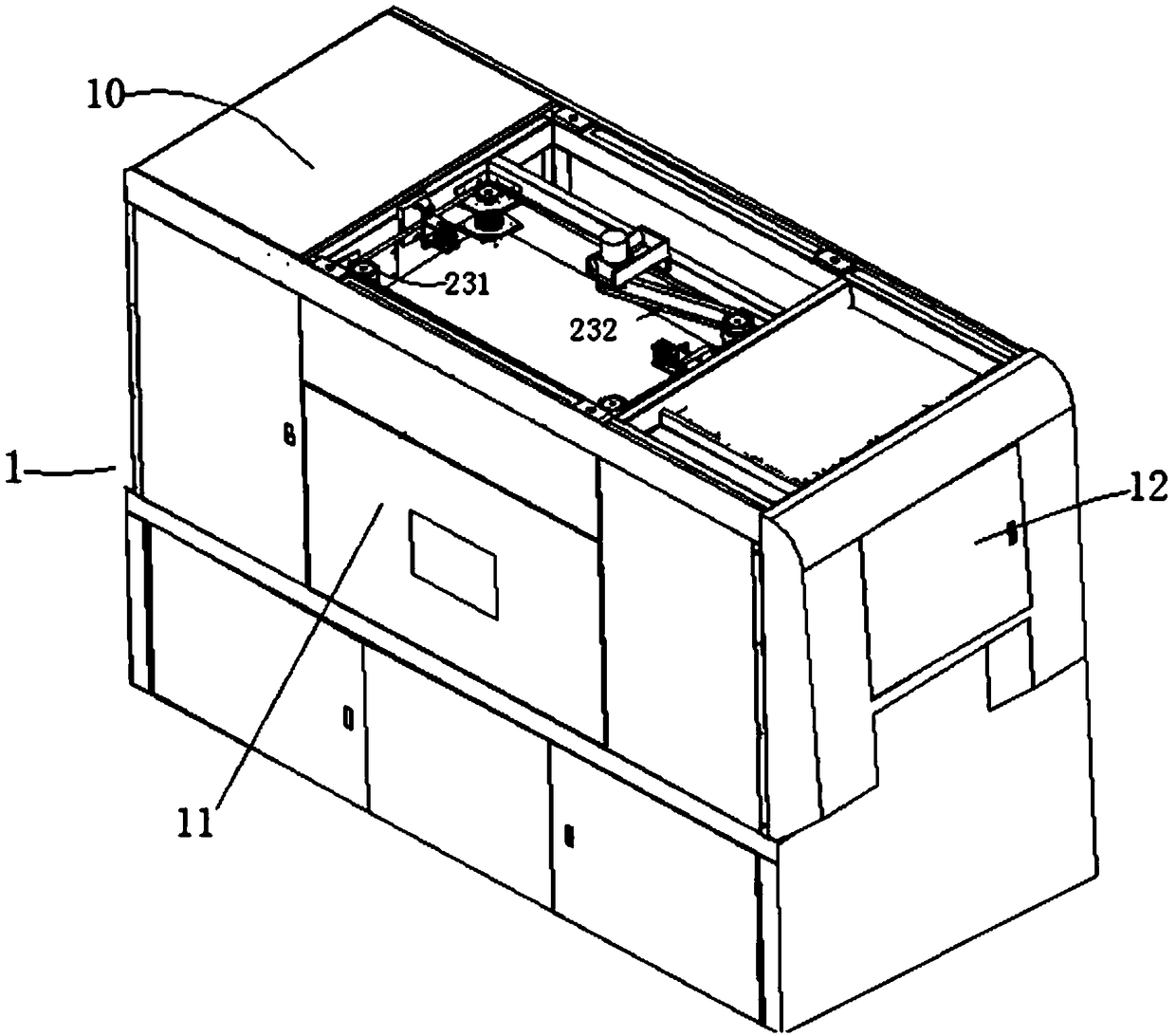

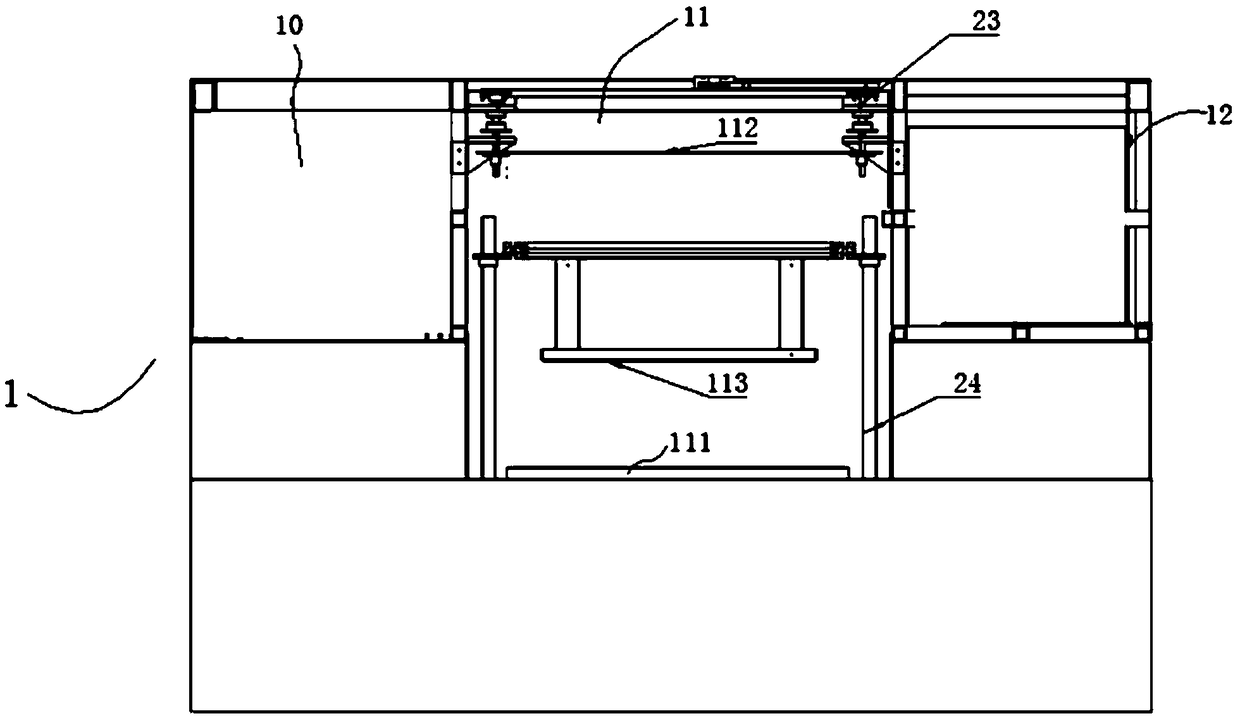

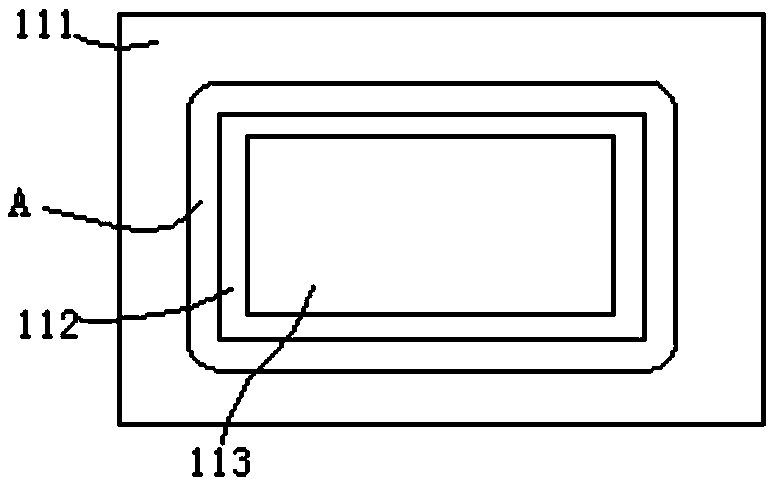

[0037] The high-frequency thawing device of this embodiment has a box-type structure, and is used for thawing a small amount of frozen food, and the frozen foods are put into the high-frequency thawing device one by one to thaw. Such as figure 1 , figure 2 As shown, the box body 1 is divided into multiple compartments for arranging the high-frequency cabin 10, the thawing cabin 11, the electric control cabin 12, and the like. Such as figure 1As shown, a high-frequency generator is provided in the high-frequency generating cabin 10, which is used to provide a high-frequency electric field between the positive plate group and the negative plate 111 of the thawing cabin 11, and various components that generate high-frequency oscillations are installed therein, such as , vacuum electron tubes, capacitors, vacuum variable capacitors, inductance and choke coils and their connections, in the high-frequency generation cabin 10, compartments can also be set to install high-voltage p...

no. 2 example

[0064] Such as Figure 12 As shown, the positive plate group in this embodiment has only one positive plate, and the size of the positive plate is smaller than the cross-sectional size of the frozen food along the direction of the positive plate. The positive and negative plates can be in various planar shapes such as rectangle and square, but rectangle is preferred. The anode of the high-frequency generator is connected to the positive plate through, for example, a thin copper sheet. The cathode of the high-frequency generator and the negative plate 111 are both grounded, that is, connected to the casing 1, and the positive plate and the negative plate 111 form a heating capacitor. Apply a predetermined voltage to the anode of the high-frequency generator to generate high-frequency waves between the positive plate and the negative plate 111. The high-frequency waves have a better penetration depth and can preferentially thaw frozen food A from the most difficult position insi...

no. 3 example

[0074] Combine below Figures 11 to 13 The third embodiment will be described. In the high-frequency thawing device of this embodiment, a conveying mechanism 51 is added on the basis of the box body 1 , and multiple rows and rows of thawing areas are set in the thawing cabin 11 . The conveying mechanism 51 uses a belt to convey the frozen food A. The conveying belt 511 runs through the entire box from left to right. The conveying belt 511 penetrates from one side of the box, passes through the thawing cabin 11, and exits from the other side of the box. The article is thawed in the thawing cabin 11. Driving and transmission components such as a conveying motor and a belt pulley for driving the conveying belt are installed below the conveying belt 511 .

[0075] Such as Figure 15 , Figure 16 As shown, in the thawing cabin 11, there are a plurality of thawing areas arranged at intervals, wherein each thawing area includes a horizontal positive plate group and a negative pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com