Prefabricated type foundation pit support for environment-friendly underground garage and construction method thereof

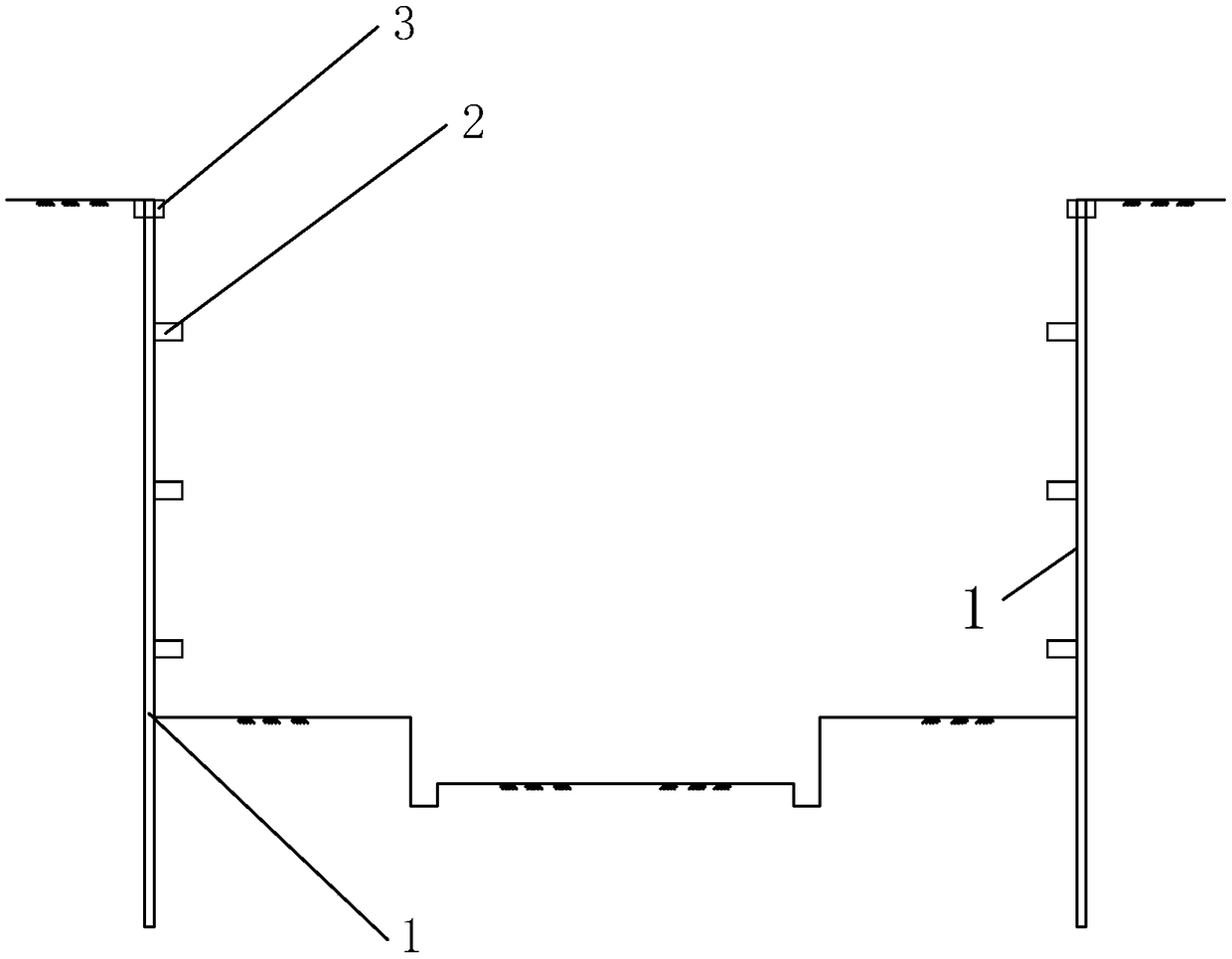

A technology for the protection of underground garages and foundation pits. It is applied in excavation, construction, and infrastructure engineering. It can solve problems such as loss of function, waste of resources, and failure of secondary use of the enclosure structure, achieving a high degree of mechanization. Safety and comfort, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The prefabricated enclosure pile 1 includes several enclosure steel members spliced together, the enclosure steel members are arranged in an H shape, and the enclosure steel members include two flange plates and connecting two wing panels. The connecting plate 8 of the flange plate, the two ends of the flange plate are provided with locks, and the two locks on the same flange are a male and a female, which are respectively 9 male locks and 10 female locks. pieces, and the male and female buckles 10 on every two mutually spliced flange plates are arranged crosswise, and the flange plates include a first flange plate 11 and a second flange plate 12, and the first flange plate The length of 11 is longer than the length of the second flange plate 12 .

Embodiment 2

[0024] Embodiment 2: The prefabricated enclosure pile 1 includes several enclosure steel components spliced together, the enclosure steel components include a first steel component 13 and a second steel component 14, and the first steel component 13 is in the shape of a U Type setting, the second steel member 14 is n-type setting, both ends of the first steel member 13 and the second steel member 14 are provided with cogs 15, the first steel member 13 and the second steel member 14 are connected by tooth mouth 15.

[0025] A prefabricated foundation pit enclosure and construction method for an environment-friendly underground garage, which is characterized in that it includes the following steps: (1) After the design site is leveled, the fixed base of the prefabricated steel top ring beam 3 is poured to facilitate Install the prefabricated steel roof ring beam 3; (2) install and fix the arc-shaped prefabricated steel members 6 in sequence to form a circular closed prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com