Dust removal device for furniture polishing

A technology for dust removal equipment and furniture, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., which can solve problems such as unfavorable life safety of workers, reduced production efficiency, and physical damage to workers, so as to achieve a safe and comfortable working environment and reduce Production cost, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

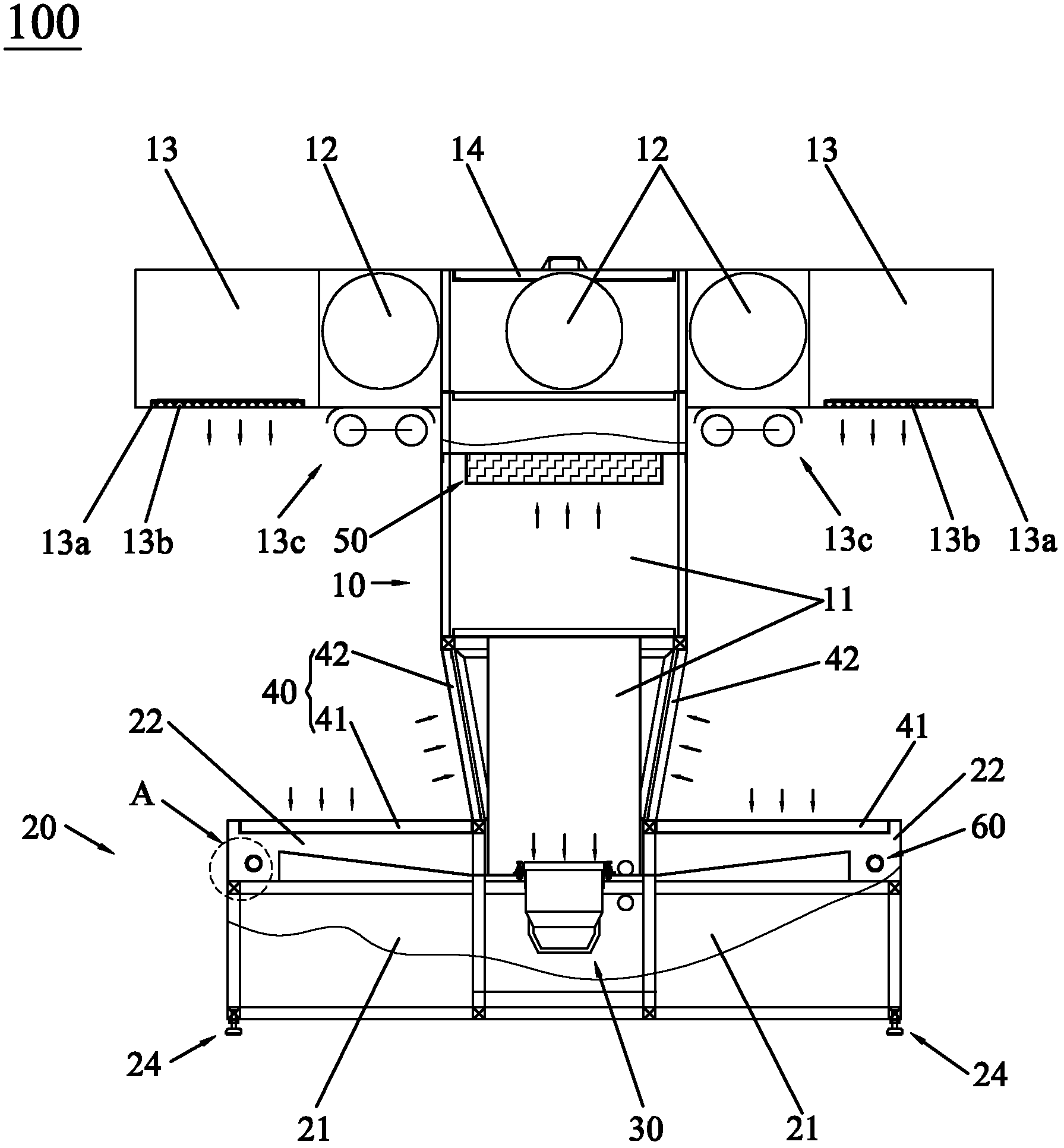

[0017] see Figure 1 to Figure 3 , the dust removal equipment 100 for furniture polishing of the present invention is used to absorb and treat the dust generated during the polishing process and the harmful substances in the dust. Wherein, the dust removal equipment 100 for furniture polishing of the present invention includes a polishing table 20 , a cavity 10 , an exhaust fan (not shown in the figure), a hydrocyclone 30 , a suction hole plate 40 and a filter layer 50 . The chamber body 10 is arranged above the polishing table 20. The chamber body 10 has an upper processing chamber 11 sealed from the outside world. The top of the chamber body 10 is provided with an exhaust pipe 12 communicating with the upper processing chamber 11. The exhaust fan is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com