A UV led burn-in bench suitable for surface mount

A surface mount, ultraviolet technology, applied in the field of ultraviolet LED production equipment, can solve the problems of inability to find dead lights, glare, and blindness in time, and achieve good market application value, high accuracy, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

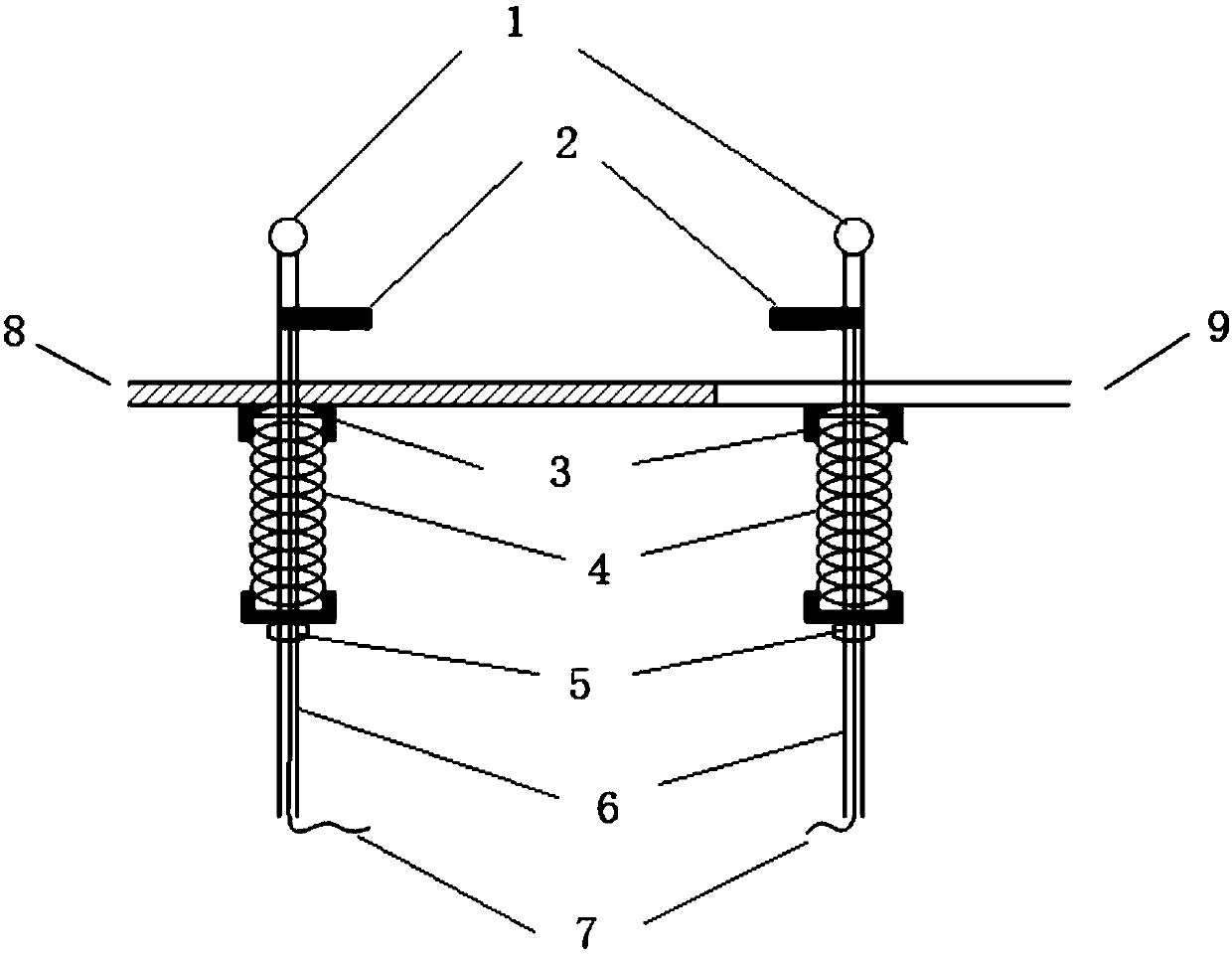

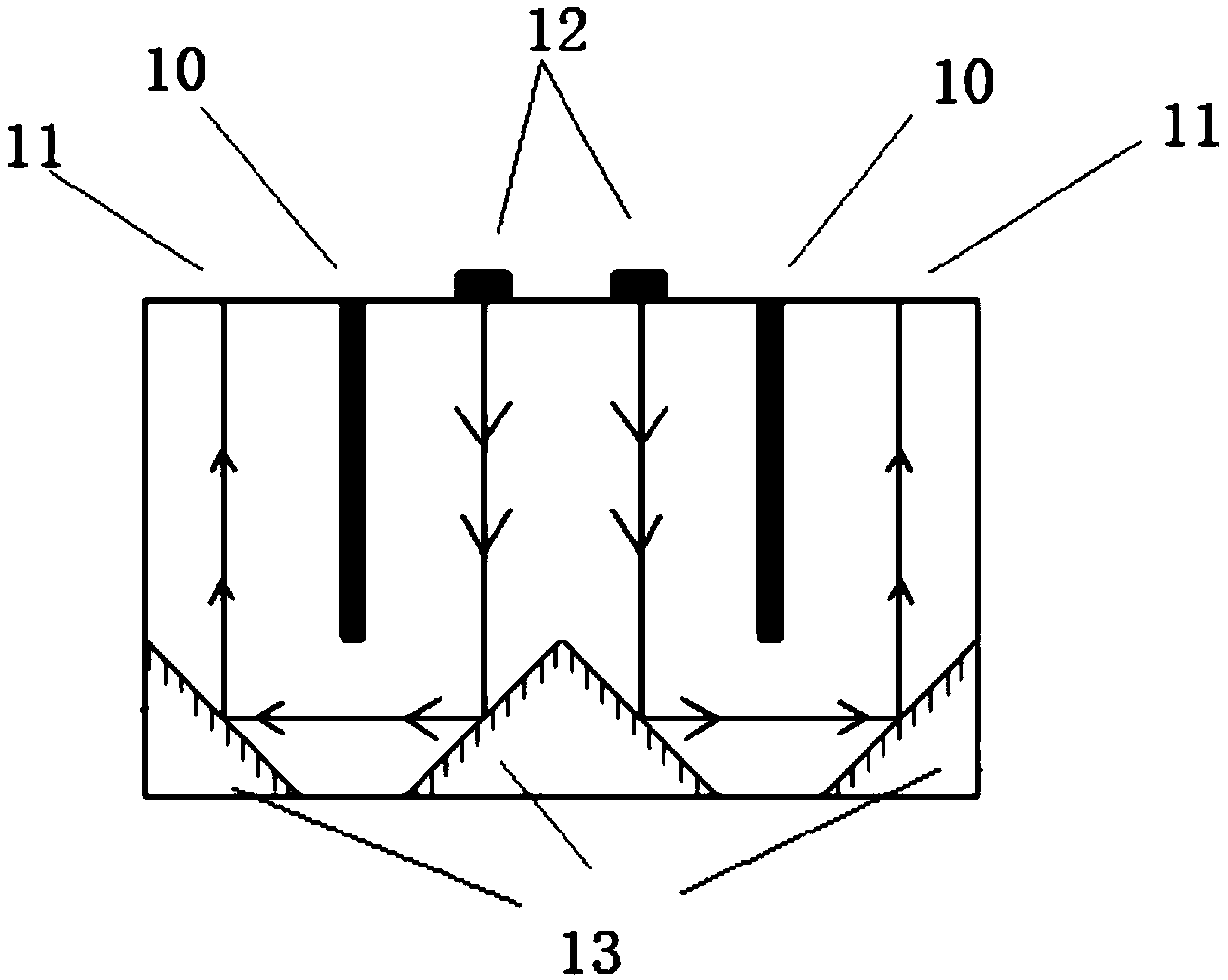

[0025] see figure 1 , in an embodiment of the present invention, a UV LED burn-in station suitable for surface mounting, including LED electrode clips 2, springs 4, fixing bolts 5, hollow screws 6, positive and negative wires 7, an operation panel 8, and adjustable rails 9 , partition 10 and observation window 11, two hollow screw rods 6 run through the operation panel 8, LED electrode clips 2 and handle 1 are respectively installed on the top of the hollow screw rods 6, springs 4 and fixing bolts 5 are installed at the ends, and the fixing bolts 5 are only fixed on The end of the hollow screw 6 prevents the spring 4 from falling off, and the other end of the spring 4 is blocked by the operation panel 8. When the operator lifts up the handle 1, the hollow screw 6 moves upward, and the LED electrode clip 2 leaves the operation panel 8, fixing the bolt 5 and operating The space between the panels 8 shrinks, and the spring 4 shrinks. At this time, the LED electrode is placed dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com