Method for treating catalyst production wastewater

A technology for producing wastewater and treatment methods, which is applied in water/sewage treatment, chemical instruments and methods, and neutralized water/sewage treatment, etc. It can solve the problems of low cost, only mixed salt crystals can be obtained, and high cost of wastewater treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

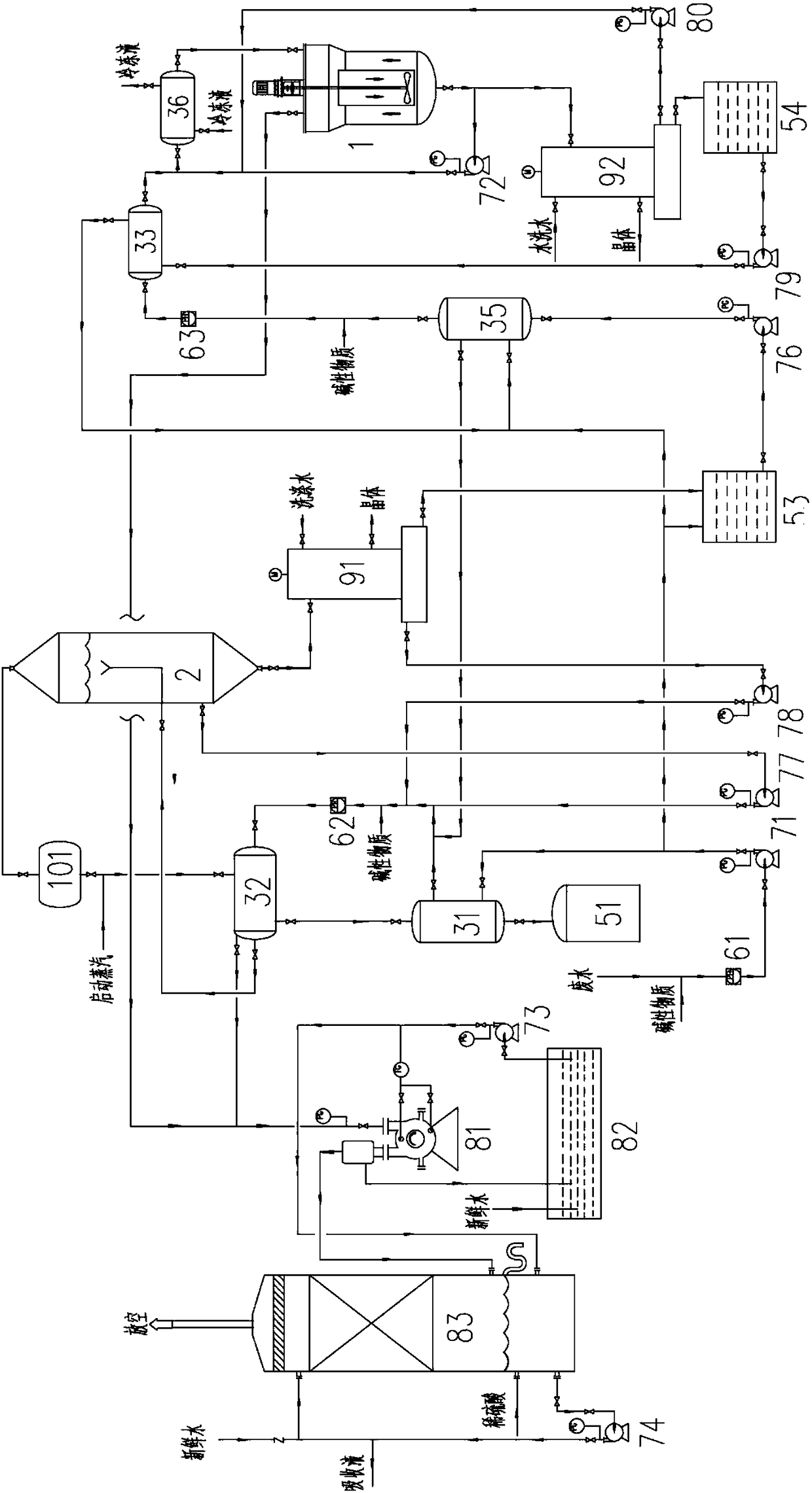

[0112] Such as figure 1 As shown, the catalyst production wastewater (containing NaCl 120g / L, Na 2 SO 4 48g / L, NH 4 Cl23g / L, (NH 4 ) 2 SO 4 9.35g / L, pH 6.8) with a feed rate of 8.40m 3 The speed of / h is sent into the pipeline of the treatment system, and the sodium hydroxide aqueous solution that imports concentration is 45.16 mass % in the pipeline is carried out the pH value adjustment for the first time, by the first pH value measuring device 61 (pH meter) after adjusting The pH value is monitored (measured value is 9.1); Then by the first circulating pump 71 the 3.40m 3 / h Catalyst production wastewater is sent to the first mother liquor tank 53 to mix with the first mother liquor, another part of catalyst production wastewater is sent to the first heat exchange device 31 to exchange heat with the first ammonia-containing steam condensate, and the rest of the catalyst production wastewater After mixing with the second mother liquid returned by the ninth circulati...

Embodiment 2

[0119] Carry out the treatment of catalyst production waste water according to the method for embodiment 1, difference is: to containing NaCl68g / L, NaCl68g / L, NaCl 2 SO 4 100g / L, NH 4 Cl 24g / L, (NH 4 ) 2 SO 4 35.9g / L, pH 6.7 catalyst production wastewater for treatment, feed volume is 13.3m 3 / h; set 5.0m 3 Cl - and SO 4 2- The molar ratio is 18.948; The rest of the catalyst production waste water is mixed with the first mother liquor in the first mother liquor tank 53, and the concentration of NaCl in the gained mixed liquor is 247.0g / L, NaCl 2 SO 4 The concentration is 43.6g / L.

[0120] The evaporation temperature is 75°C, the pressure is -72.75kPa, and the evaporation volume is 8.90m 3 / h; the cooling crystallization temperature is -2°C, and the time is 120min.

[0121] The first solid-liquid separation device 91 obtains water content per hour and is 1462.30kg of sodium chloride crystallization filter cake of 15% by mass, and finally obtains 1242.96kg of sodium...

Embodiment 3

[0125] Carry out the treatment of catalyst production waste water according to the method for embodiment 1, difference is: to containing NaCl99g / L, NaCl99g / L, NaCl 2 SO 4 101g / L, NH 4 Cl 26g / L, (NH 4 ) 2 SO 4 27g / L, pH 6.9 catalyst production wastewater for treatment, feed volume is 12.15m 3 / h; set 5.0m 3 Cl - and SO 4 2- The molar ratio is 16.938; The rest of the catalyst production waste water is mixed with the first mother liquor in the first mother liquor tank 53, and the concentration of NaCl in the mixed liquor obtained is 238.5g / L, NaCl 2 SO 4 The concentration is 47.1g / L.

[0126] The evaporation temperature is 50°C, the pressure is -92.67kPa, and the evaporation volume is 8.76m 3 / h; the cooling crystallization temperature is -4°C, and the time is 120min.

[0127] The first solid-liquid separation device 91 obtains 1788.93 kg of sodium chloride crystallization filter cake with a water content of 14 mass % per hour, and finally obtains 1538.48 kg of sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com