Developing and producing method of intelligent power-assisting robot system based on heavy load carrying

A robot system and robot technology, applied in manipulators, manufacturing tools, etc., to achieve the effects of light weight, high stability, great economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

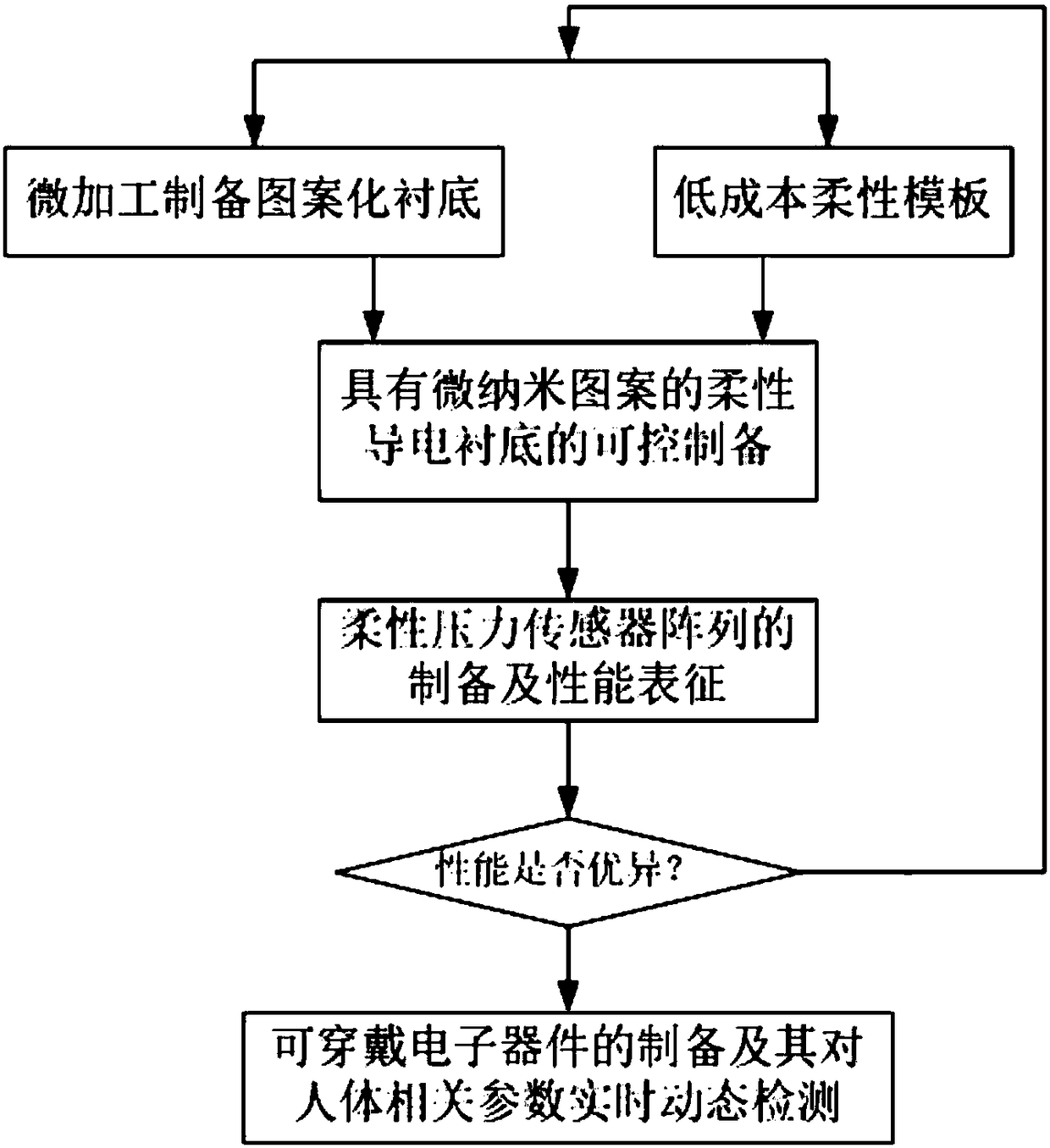

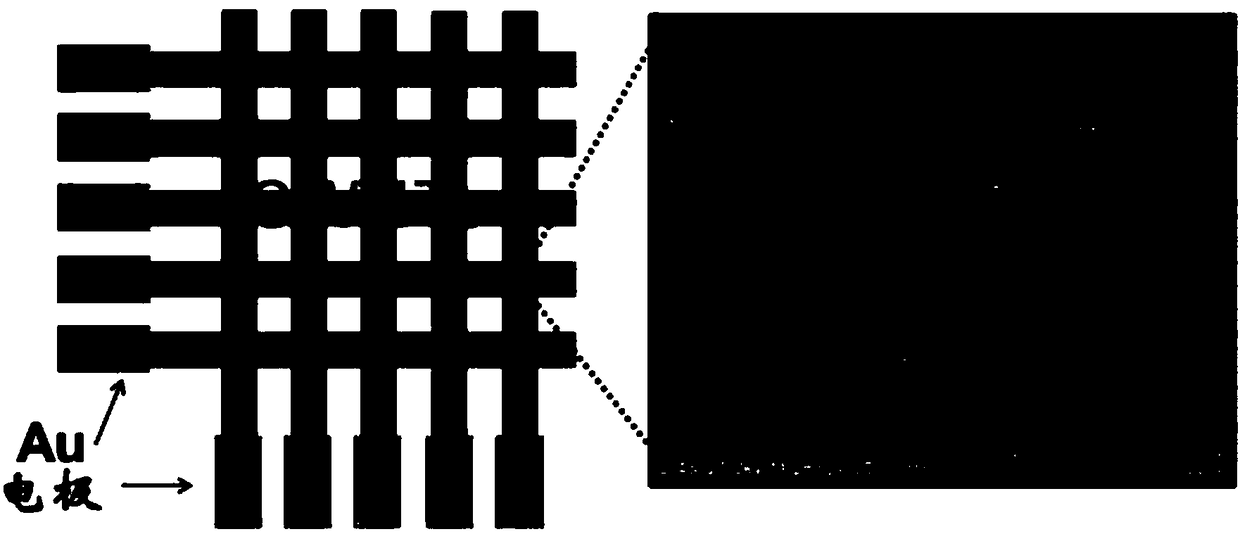

[0034] see figure 1 , the present invention provides a technical solution: a method for developing an intelligent power-assisted robot system based on heavy-duty handling, comprising the following steps:

[0035] Step (S100): Research on the characteristics and laws of human body movement: use high-speed photography system, three-dimensional laser dynamic test system, and six-dimensional force sensor system to analyze the instantaneous movements of various parts of the human body, especially the joints of the arms / lower limbs, during the process of human body transportation Quantitative analysis of the state and force, and the construction of a human body handling model and a database of motion characteristics;

[0036] First, by studying the volume, weight, moment of inertia, joint form, and range of motion of the main parts of the human body, it provides a basis for determining the degrees of freedom, size, weight configuration, joint form, range of motion, and driving mode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com