Nickel single-active site graphite-phase carbon nitride-based photocatalytic material as well as preparation method and application thereof

A technology of graphitic carbon nitride and photocatalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc. Promote catalytic ability and other issues to achieve the effect of reducing production costs, improving efficiency, and improving the response to visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

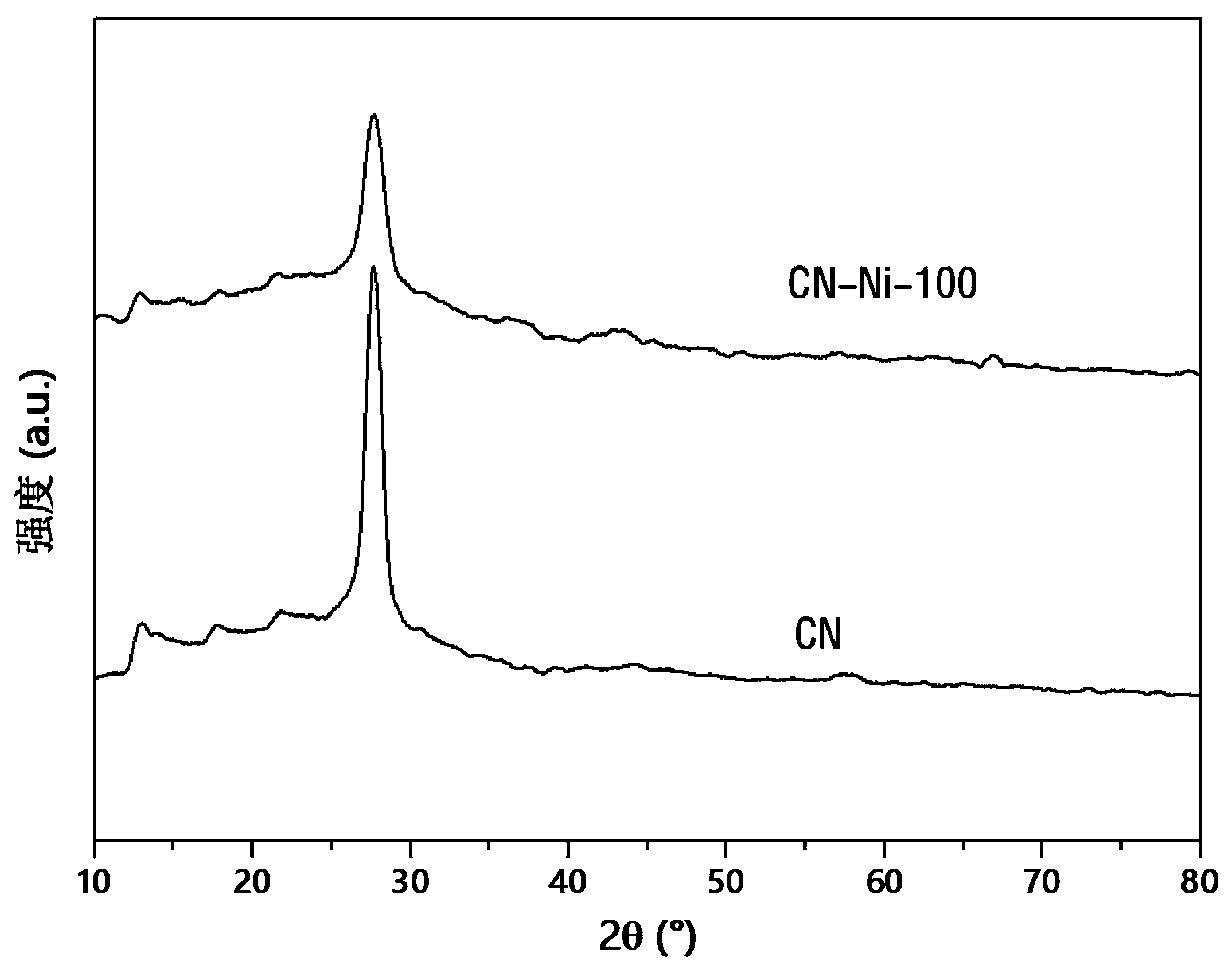

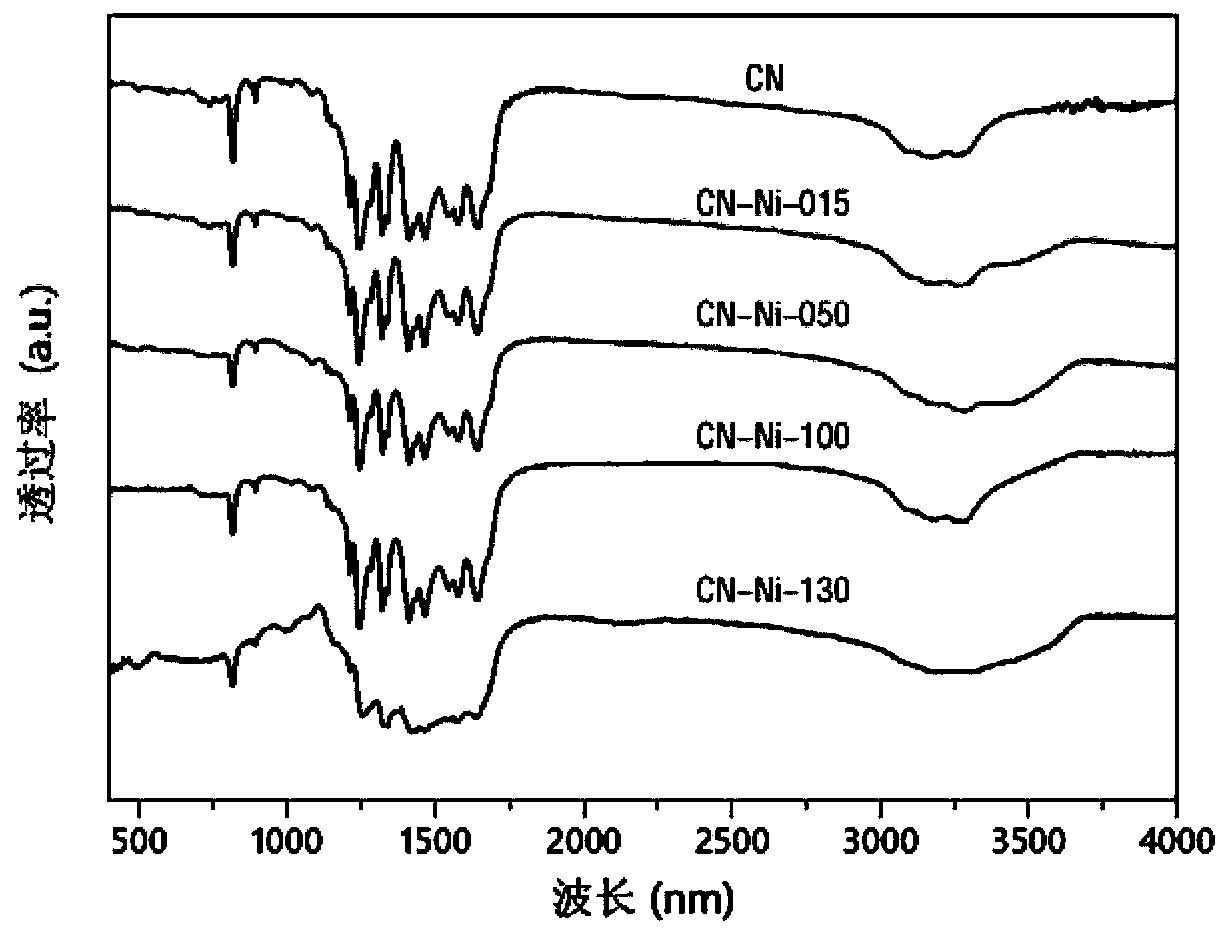

Embodiment 1

[0040] Mix 10g urea with 100mg NiCl 2 ·6H 2 O was added to 50ml of deionized water, and stirred at room temperature to completely dissolve the two to form a mixed solution. Next, the above mixed solution was evaporated and concentrated to 10 ml at a constant temperature of 70° C., and then placed in liquid nitrogen and quickly frozen into ice. After the mixed solution ice is further pulverized and finely ground, it is placed in a freeze dryer to dry overnight, and excess solvent is removed to obtain the mixed precursor powder. The obtained precursor powder was transferred to a corundum crucible, and calcined at 550°C for 2 hours to obtain a nickel single active site graphite phase carbon nitride-based photocatalytic material, which was designated as CN-Ni-100;

[0041] Through nitrogen adsorption-desorption experiments, the specific surface area of CN-Ni-100 was measured to be 172.9m 2 / g;

[0042] Add 50 mg of the obtained sample to a mixed solution of 100 ml of water a...

Embodiment 2

[0044] Mix 10g urea with 50mg NiCl 2 ·6H 2 O was added to 50ml of deionized water, and stirred at room temperature to completely dissolve the two to form a mixed solution. Next, the above mixed solution was evaporated and concentrated to 10 ml at a constant temperature of 70° C., and then placed in liquid nitrogen and quickly frozen into ice. After the mixed solution ice is further pulverized and finely ground, it is placed in a freeze dryer to dry overnight, and excess solvent is removed to obtain the mixed precursor powder. The obtained precursor powder was transferred to a corundum crucible, and calcined at 550°C for 2 hours to obtain a nickel single active site graphite phase carbon nitride-based photocatalytic material, which was designated as CN-Ni-050;

[0045] Through nitrogen adsorption-desorption experiments, the specific surface area of CN-Ni-50 was measured to be 144.4m 2 / g;

[0046] Add 50 mg of the obtained sample to a mixed solution of 100 ml of water and...

Embodiment 3

[0048] Mix 10g urea with 130mg NiCl 2 ·6H 2 O was added to 50ml of deionized water, and stirred at room temperature to completely dissolve the two to form a mixed solution. Next, the above mixed solution was evaporated and concentrated to 10 ml at a constant temperature of 70° C., and then placed in liquid nitrogen and quickly frozen into ice. After the mixed solution ice is further pulverized and finely ground, it is placed in a freeze dryer to dry overnight, and excess solvent is removed to obtain the mixed precursor powder. The obtained precursor powder was transferred to a corundum crucible, and calcined at 550°C for 2 hours to obtain a nickel single active site graphite phase carbon nitride-based photocatalytic material, which was designated as CN-Ni-130;

[0049] Through nitrogen adsorption-desorption experiments, the specific surface area of CN-Ni-130 was measured to be 102.6m 2 / g;

[0050] Add 50 mg of the obtained sample to a mixed solution of 100 ml of water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com