Manufacture method for ceramic heating device used for intelligent pedestal pan

A manufacturing method, ceramic heating technology, applied to immersion heating devices, ohmic resistance heating parts, ohmic resistance waterproof/airtight, etc., can solve the problems of low production rate, bursting of ceramic heating pieces, and different water flow speeds of ceramic heating pieces and other issues to achieve the effect of reducing difficulty and consistent water flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

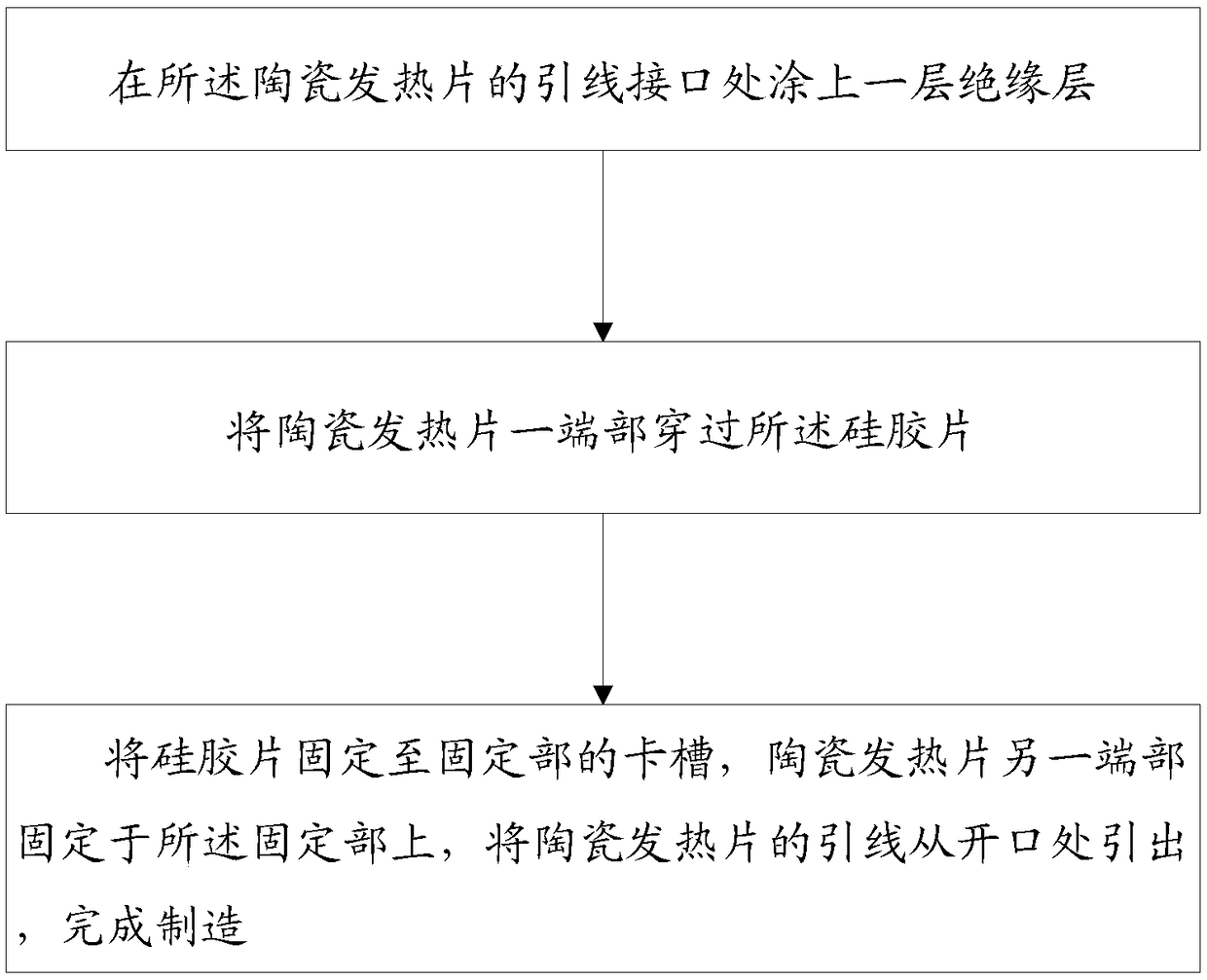

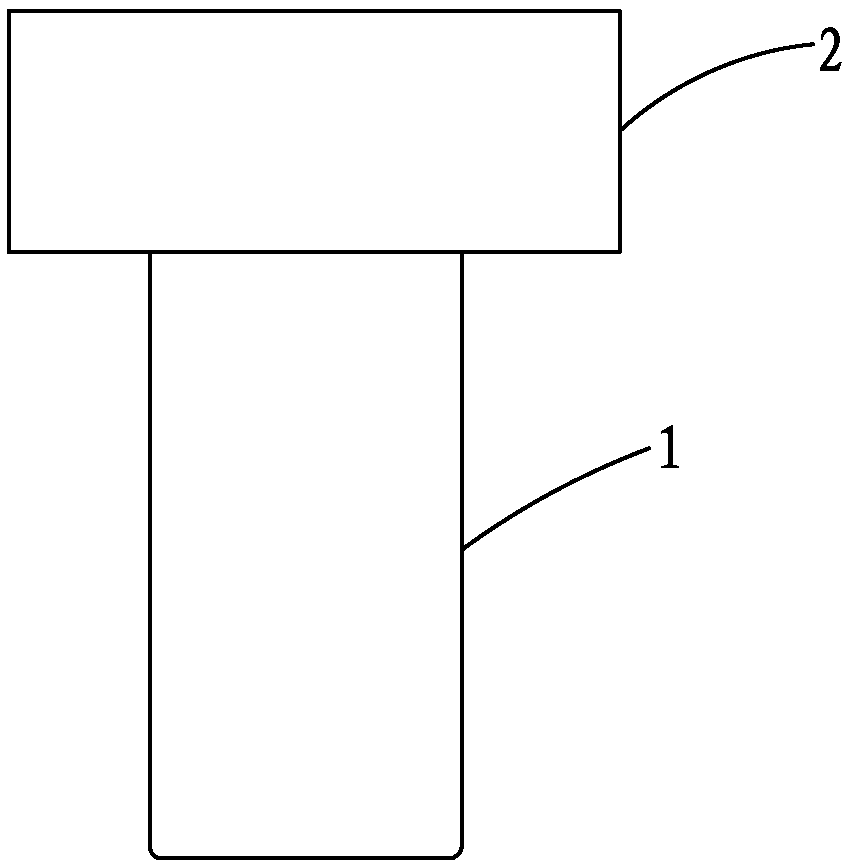

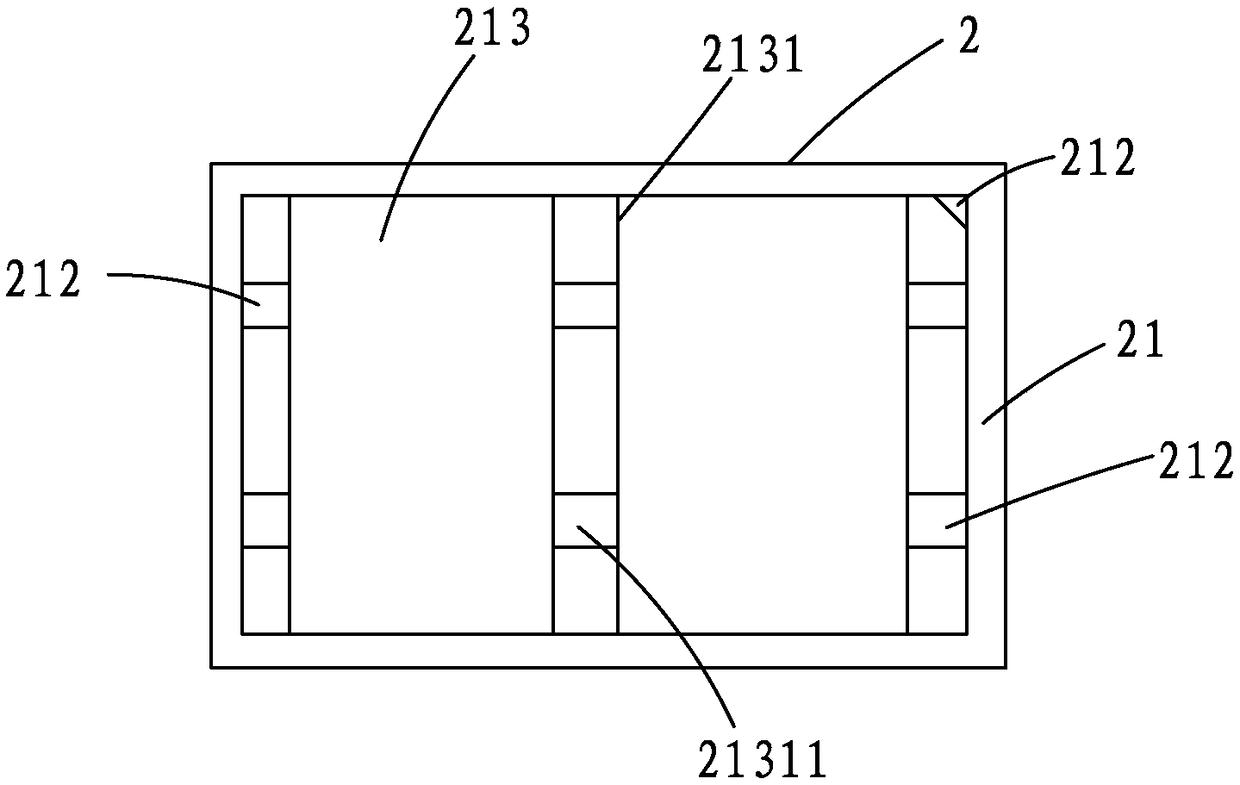

[0026] Such as figure 1 As shown, the manufacturing method of the ceramic heating device used in the intelligent toilet of the present invention specifically includes a ceramic heating sheet, a fixing part and a silica gel sheet, the silica gel sheet is provided with at least one fixing hole, and the fixing hole and the ceramic heating sheet interference fit, the fixing part is provided with a card slot, and the card slot is provided with an opening, comprising the following steps:

[0027] Step 1, coating an insulating layer on the lead interface of the ceramic heating sheet;

[0028] Step 2, passing one end of the ceramic heating sheet through the silica gel sheet;

[0029] Step 3. Fix the silicone sheet to the slot of the fixing part, and lead the lead wire of the ceramic heating sheet out from the opening to complete the manufacture.

[0030] The manufacturing method of the ceramic heating sheet is as follows: cutting the cast sheet after isostatic lamination to form a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com