Driving assembly

A technology for driving components and components, applied in electric components, electrical components, control mechanical energy and other directions, can solve the problems of small adaptable temperature range, low positioning accuracy, large transmission error, etc., and achieves compact structure, high transmission precision, and motion. The effect of small hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

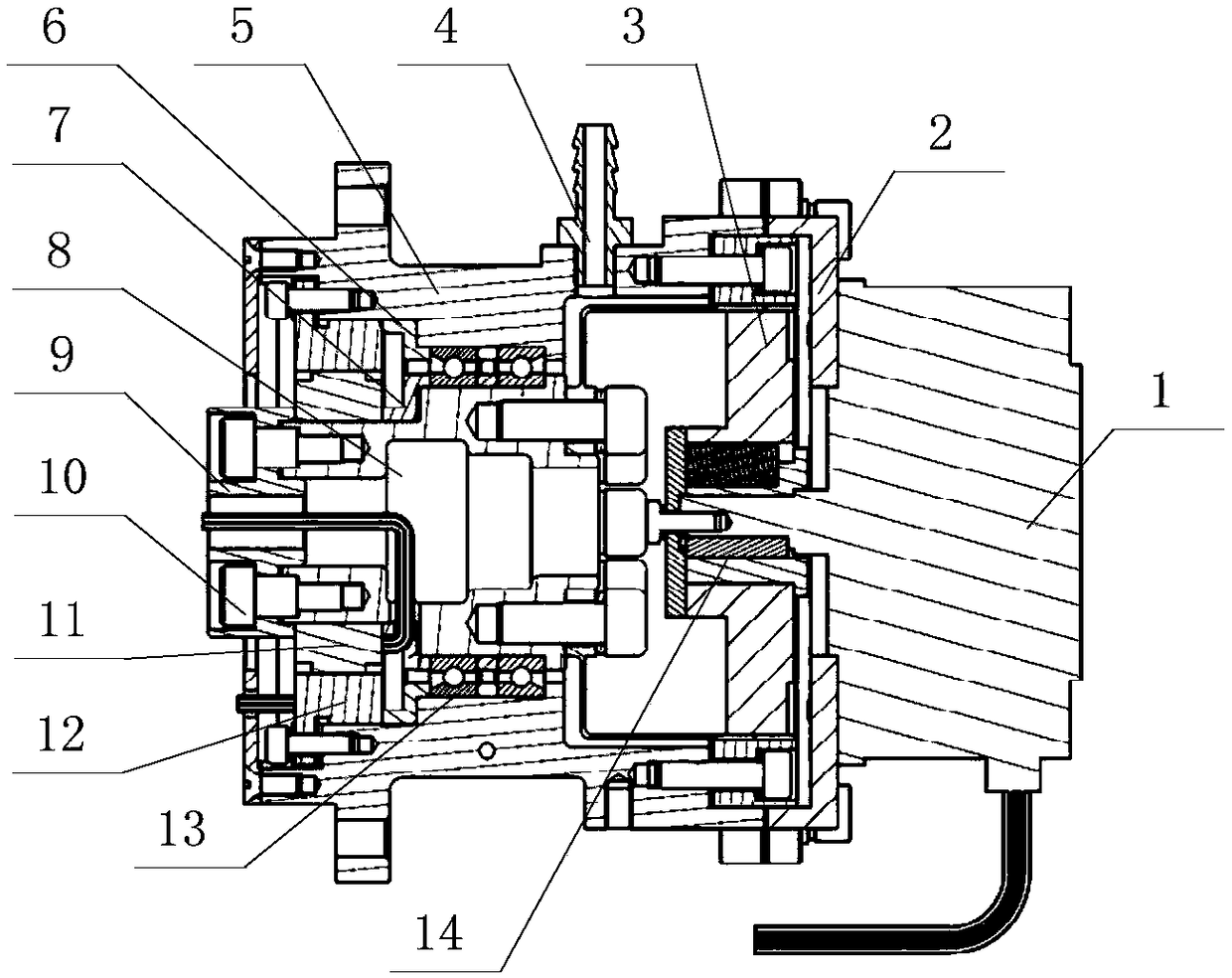

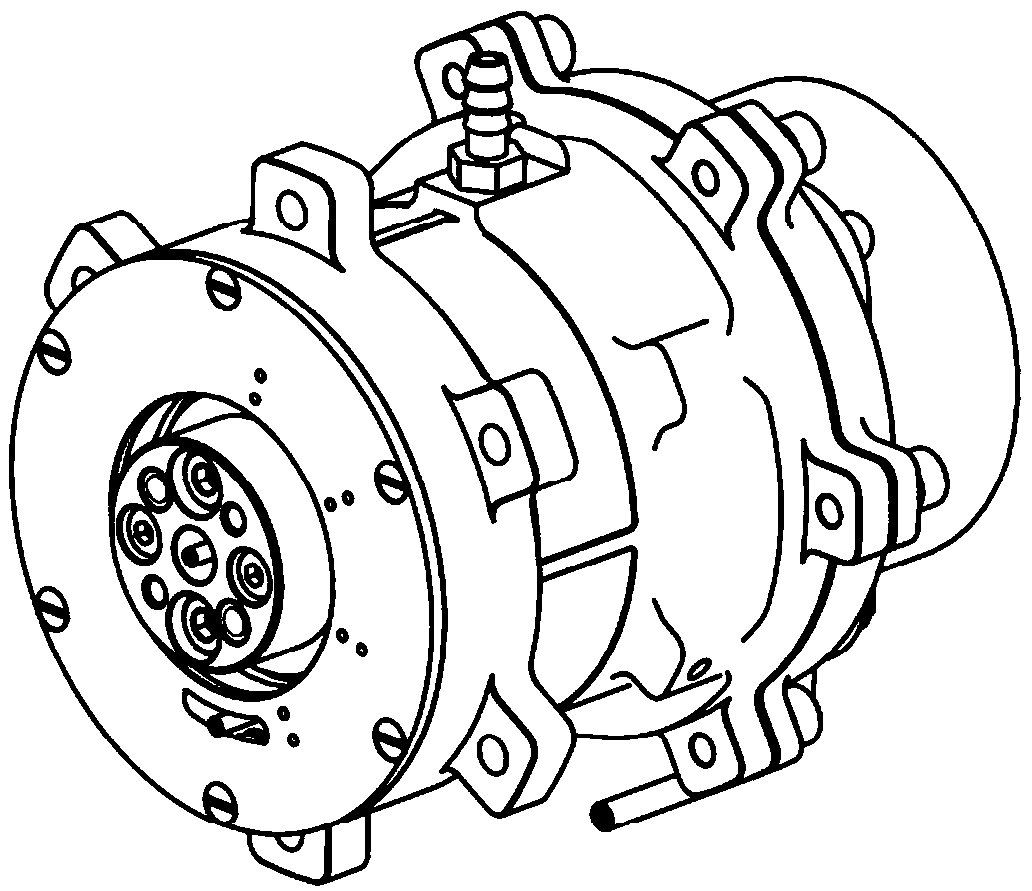

[0026] Such as figure 1 and 2 As shown, the present invention provides a drive assembly, including: drive motor 1, motor mounting end cover 2, harmonic reducer 3, assembly housing 5, drive shaft 8, adapter flange 9, pin screw 10, resolver , angular contact bearing assembly 13, flat key 14, wherein,

[0027] The drive motor 1 and the motor installation end cover 2 are positioned through a seam and fixed with screws;

[0028] The output shaft of the drive motor 1 is fixedly connected to the input end of the harmonic reducer 3, and the torque transmission is performed using a flat key 14;

[0029] The fixed end of the harmonic reducer 3 is installed between the motor installation end cover 2 and the component housing 5;

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com