A triangular prism-type deployable planar film antenna mechanism

A technology of triangular prism and unfolding mechanism, which is applied in the direction of folding antennas, etc., can solve the problems of complex driving mechanism, low reliability of unfolding, and increased structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

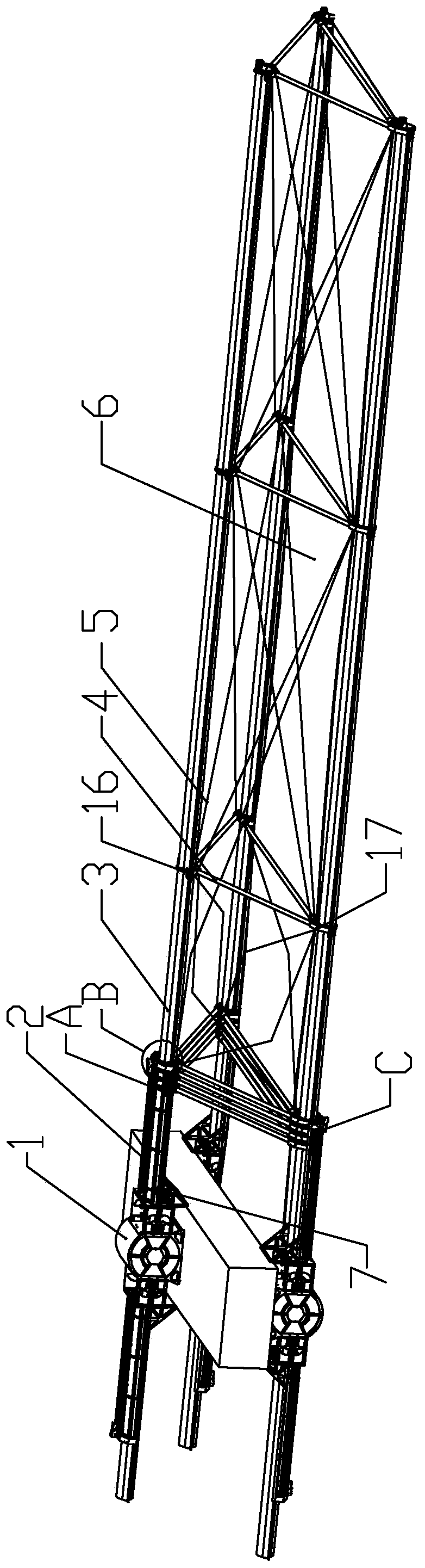

[0023] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, a triangular prism-type expandable planar film antenna mechanism of this embodiment, including an elastic extension rod deployment mechanism 1; it also includes two pulley locking mechanisms and multiple pulley mechanisms, and the two pulley locking mechanisms Symmetrically installed on the left and right sides of the elastic stretch rod expansion mechanism 1, each pulley locking mechanism is locked with a plurality of pulley mechanisms, and the multiple pulley mechanisms are formed by the stretching of the three elastic stretch rods 3 of the elastic stretch rod expansion mechanism 1. Prismatic truss unit; each pulley locking mechanism includes a slideway 2, a guide mechanism 7, a motor 8, a right-angle reducer 9, a limit block 11, a spring limit clip 27 and a locking assembly, and one end of the slideway 2 is connected to the elastic The side end faces of the extension rod expansi...

specific Embodiment approach 2

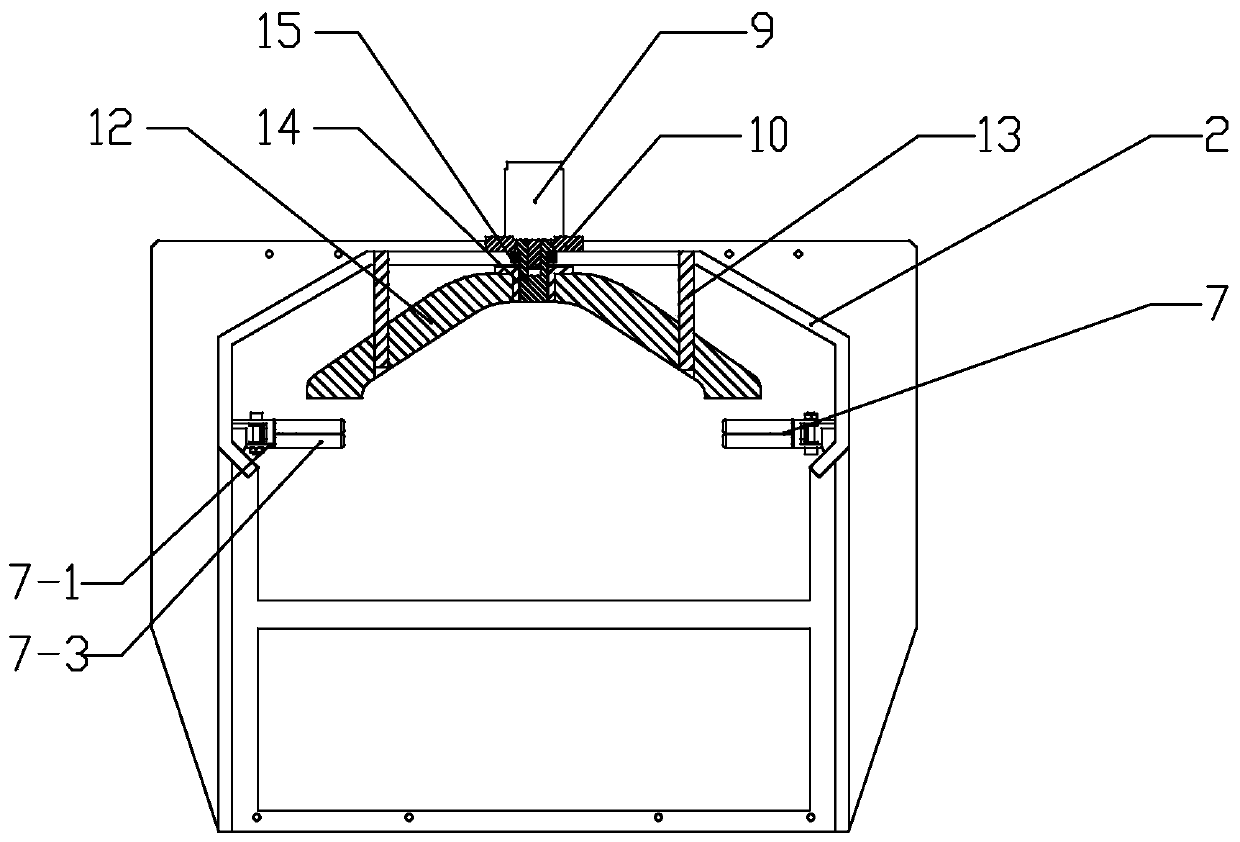

[0029] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment. The locking assembly of this embodiment includes a concave arc-shaped compression sleeve 12, a threaded sleeve 14 and a threaded column 15. The threaded column 15 is connected to the output end of the right-angle reducer 9. The threaded sleeve 14 is installed on the threaded column. 15, the opening of the concave arc compression sleeve 12 is installed downwards on the threaded sleeve 14. Such setting facilitates the rotation of the threaded column 15 under the control of the right-angle reducer 9, and the threaded column 15 drives the threaded sleeve 14 and the concave arc-shaped compression sleeve 12 to move up and down, thereby realizing the locking and releasing of the pulley mechanism The action and operation are simple and flexible, and other components and connections are the same as those in the first embodiment.

[0030] In the action of the pulley mechanism in this em...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination figure 2 and image 3 To illustrate this embodiment, the locking assembly of this embodiment further includes a guide strut 13 installed on the concave arc-shaped compression sleeve 12 , and the guide strut 13 slides through the slideway 2 . Such setting is convenient for ensuring precise locking and preventing errors during the locking process. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com