Underground Mechanized Continuous Mining Method of Hard Mineral Materials

A mining method and mineral material technology, which is applied in ground mining, earth square drilling, underground mining, etc., can solve the problems that cannot meet the requirements of modern mines and refining systems, the dilution rate of mineral materials remains high, and cannot guarantee safe mining, etc. , to achieve the effect of economic mining, remarkable improvement effect and saving refining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

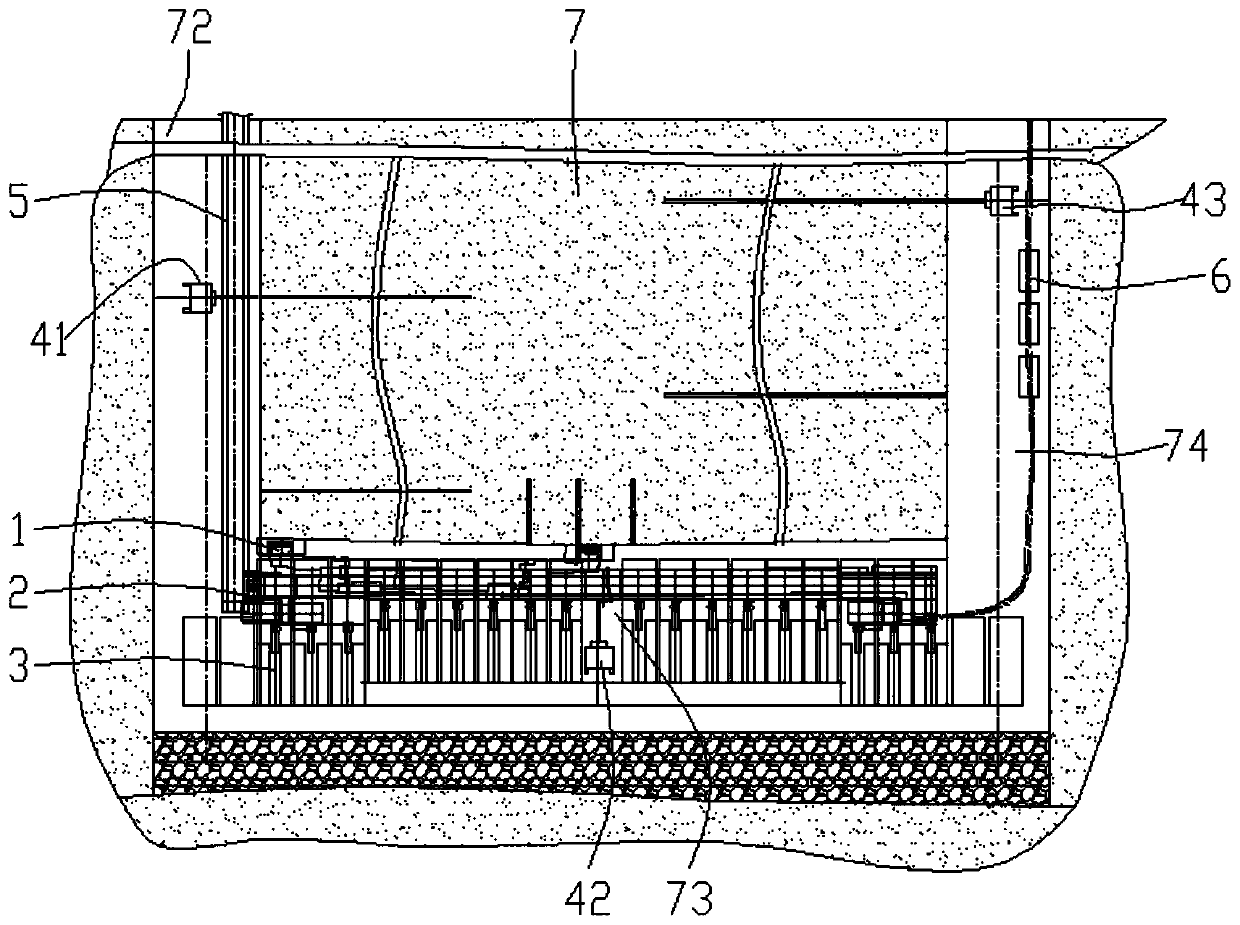

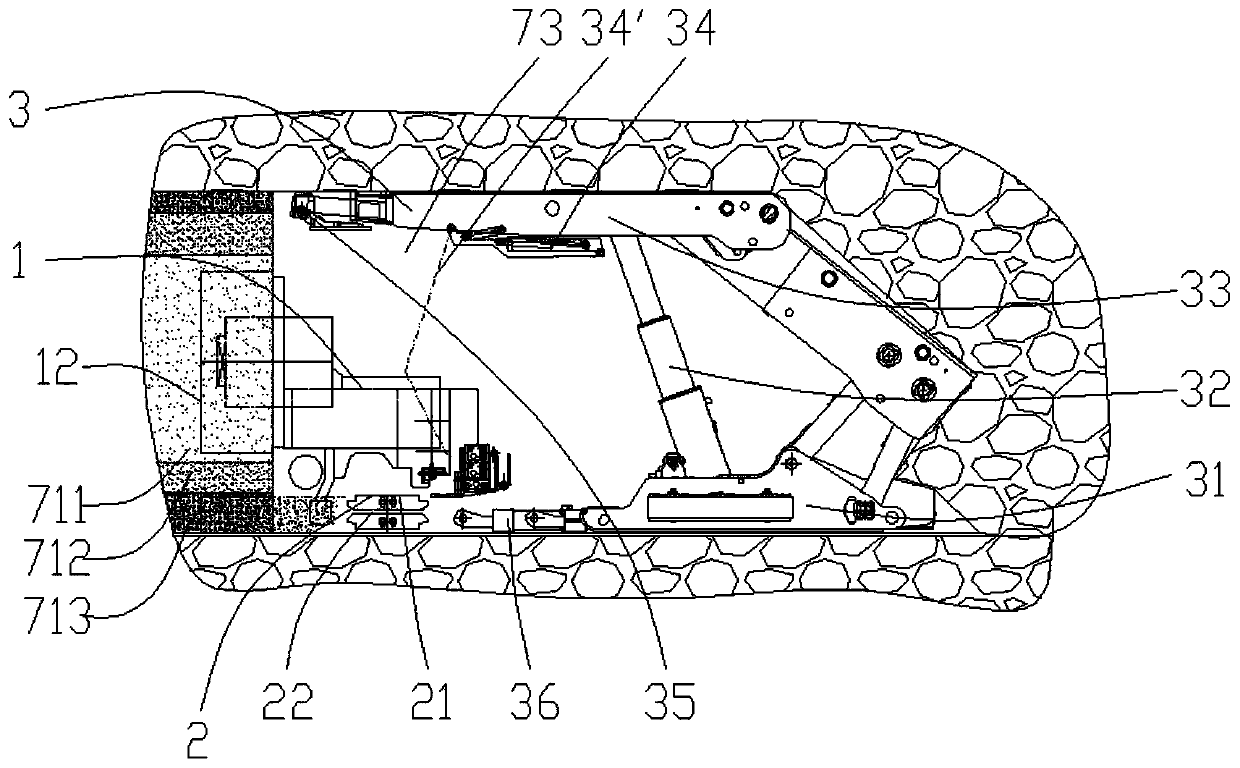

[0022] The invention discloses a mechanized continuous mining method for hard minerals, such as figure 1 As shown, a channel is first opened, around the area block 7 where the ore body planned to be mined is located, a conveying channel 72, a working face channel 73, and a power channel 74 that are connected in sequence around the area block on three sides are opened, each of which has one end. Leading to the ground, one side of the area block facing the working face passage is a working face mining wall. Then, according to the characteristics of the ore body, an initial weakening treatment is performed on the ore body of the area block. Based on the different grades of mineral materials, different mine layers are divided on the mining wall of the working face. When the minerals of the entire working face belong to the same grade of minerals, the mining wall of the working face is divided into one ore layer. Then carry out layered mining, that is, use the drum mining machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com