Design method of narrow coal pillar width in gob-side entry retention

A design method and narrow coal pillar technology, applied in design optimization/simulation, earthwork drilling, ground mining, etc., can solve problems such as paying less attention to the physical and mechanical parameters of coal pillars, and achieve good stability of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

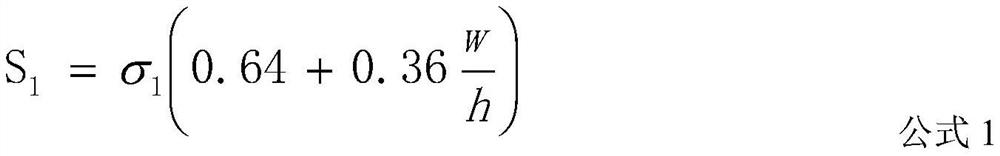

Embodiment 1

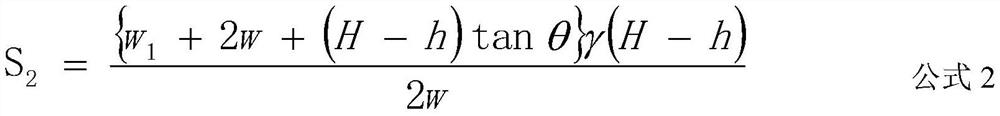

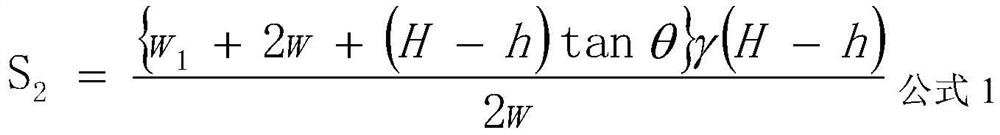

[0031] The main mining coal seams of Gaomei Co., Ltd. are 3 upper and 3 lower layers. The thickness of 3 upper coal is 2.23-8.53m, with an average thickness of 4.8m. 4.7m, 3.6m high. According to the field data, we will test the feasibility of the provided design method, and we will list the values of all parameters for ease of calculation: the uniaxial compressive strength of the coal pillar is 23Mpa, the width of the coal pillar is 4.5m, the thickness of the coal seam is 4.8m, the coal The height of the column or roadway is 3.6m, the lateral support angle θ is 20°, and the bulk density of the overburden layer on the working face is 0.027N / mm 3 And the width of the roadway is 4.7m. Through calculation, the height of the fracture zone is 48.2±5.6m. Here, 48.2m is taken. The calculated coal pillar strength is 5.01MPa, and the coal pillar stress is 4.0MPa; according to the narrow coal pillar strength and coal pillar stress The ratio of the coal pillar safety factor is 1.25. D...

Embodiment 2

[0033] The main mining coal seam of Liuxiang Coal Mine is the No. 3 coal seam, with an average thickness of 11.05m, 4.6m of coal roof mudstone and 212m of sandstone. According to the field data, we will test the feasibility of the provided design method, and we will list the values of all parameters for ease of calculation: the uniaxial compressive strength of the coal pillar is 27Mpa, the width of the coal pillar is 10m, the thickness of the coal seam is 11.05m, the coal pillar Or the height of the roadway is 3.4m, the lateral support angle θ is 20°, and the bulk density of the overburden layer on the working face is 0.027N / mm 3 And the width of the roadway is 4.86, and the height of the fracture zone is calculated to be 51.9±5.6m. Here, 51.9m is taken, and the calculated coal pillar strength is 9.2Mpa, and the coal pillar stress is 2.78Mpa; according to the narrow coal pillar strength and coal pillar stress The safety factor of the coal pillar obtained by the ratio is 3.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com