Repeatedly usable hydraulic stepping elevating system

A lifting system and hydraulic system technology, applied in the field of hydraulic stepping lift system, can solve the problems of waste of resources and high cost of lifting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

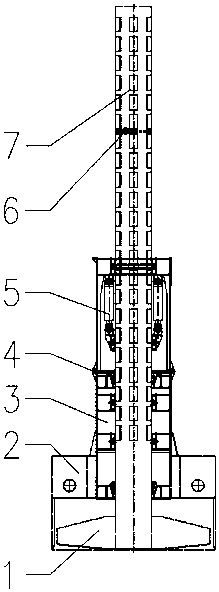

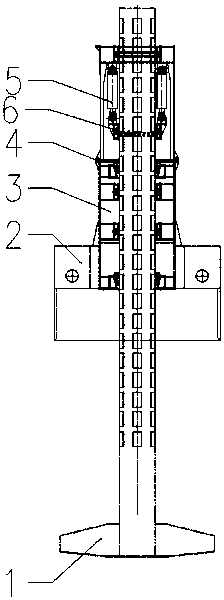

[0025] In the following, the present invention will be described in detail by taking the hydraulic ring beam step-by-step lifting system as an example in conjunction with the accompanying drawings.

[0026] Figure 1 and figure 2 As shown, a reusable hydraulic step-by-step lifting system includes a pile locking device (3) and a lifting device (5). The top of the structural cylinder (3.1) of the locking pile device (4) is welded with a butt joint The flange (3.7) has a number of bolt holes on the docking fixed flange (3.7), and the bottom of the supporting cylinder (5.1) of the lifting device (5) is a boss structure, which can be placed on the docking rotating flange (5.5 ), and prevent the butt rotating flange (5.5) from coming out from the lower end, the same number of bolt holes are opened on the butt rotating flange (5.5), and the butt fixed flange (3.7) is connected by connecting bolt 1 (4) Connect with the docking rotating flange (5.5), fix the lifting device (5) to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com