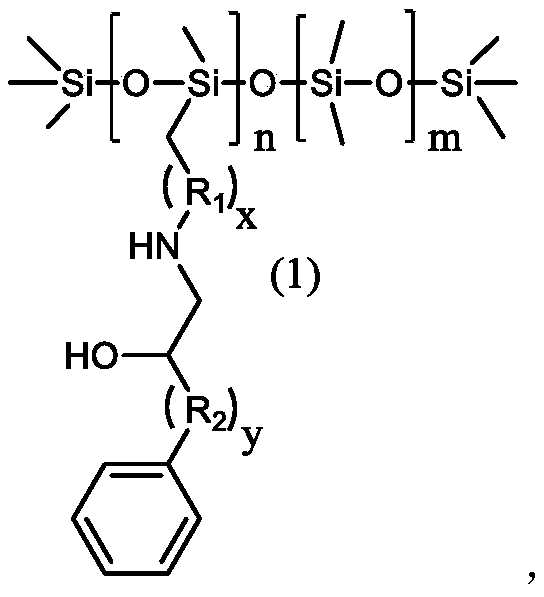

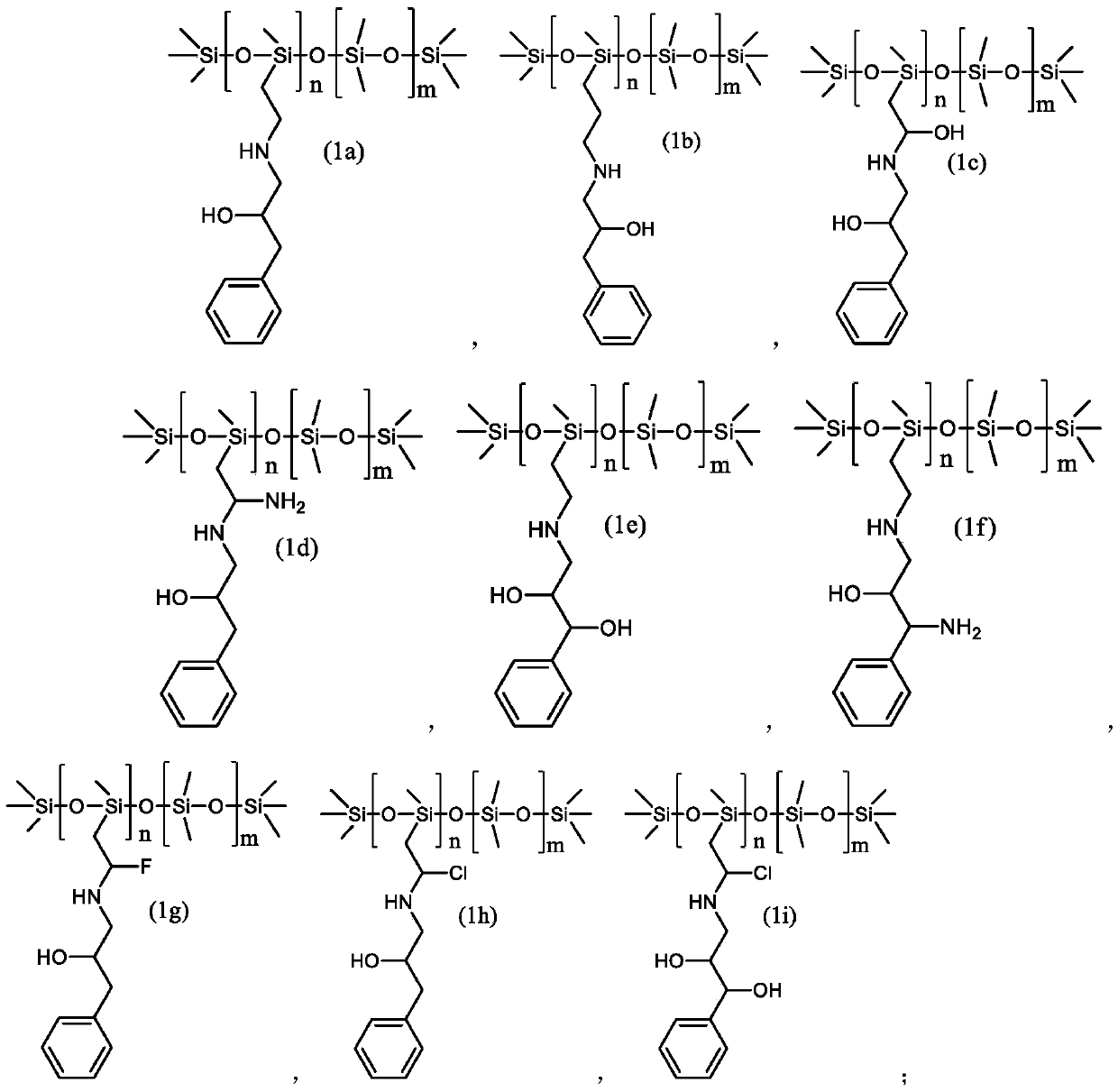

A kind of aminohydroxysiloxane polymer and preparation method thereof

A technology of aminohydroxysiloxane and polymer, which is applied in the direction of wear-resistant fiber, fiber treatment, textile and papermaking, etc., and can solve the problems of polluting textiles, poor hydrophilicity, increasing cleaning cost and difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

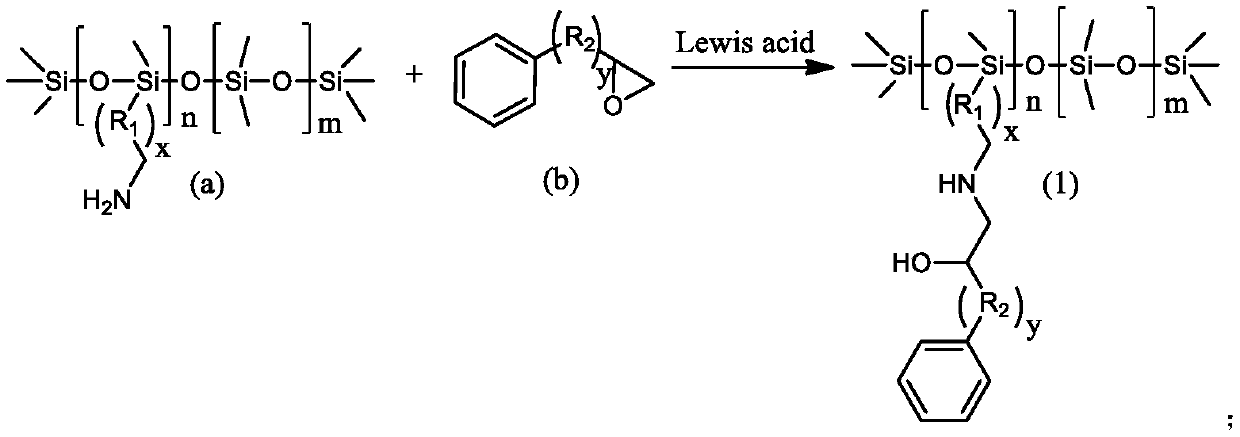

[0049] Embodiment 1, the preparation of compound (a1)

[0050] Reagents: Compound (a1) was purchased from Shenyao (Xianghe) Technology Co., Ltd.; Compound (b1) was prepared by referring to the method described in the patent US3971627A; LiClO 4 Purchased from Shanghai Zhongli Industrial Co., Ltd.

[0051] The synthetic route is as follows:

[0052]

[0053] Specific preparation method:

[0054] Dissolve 90 g of compound (a1) in 250 mL of warm THF (tetrahydrofuran), add 1 g of LiClO 4 and compound (b1), under the protection of nitrogen, control the temperature at about 150-200° C., heat to reflux, and react for 3 hours. After the reaction was complete, the mixture was filtered and the organic phase was separated. The obtained organic phase was washed successively with pure water and saturated sodium chloride, then dried with anhydrous sodium sulfate, and finally spin-dried to obtain compound (1a). The modified polysiloxane has a viscosity of about 350,000 mPa.S at 25° C....

Embodiment 2

[0059] Embodiment 2, the preparation of softening emulsion containing compound (a1).

[0060] Mix 20g of compound (a1) and 3mL of the compound of fatty alcohol polyoxyethylene ether AE09 and ester polyvinyl chloride ether SG-40 (1:2, w / w), and then add 4mL of hydrochloric acid, continue Stir until the pH range is 6-7; continue to stir the compound until a large amount of foam occurs, then slowly add 100 mL of water while stirring to obtain a microemulsion containing the compound (1a).

Embodiment 3

[0061] Embodiment 3, mechanical stability test

[0062] Sample: the sample of the comparative example was prepared according to the method described in Example 3 of the patent CN10148518A; the sample of the test example was prepared according to the method described in Example 2.

[0063] Test method: Weigh (400±0.5) g of filtered (177 μm pore size, 80-mesh filter) emulsion into a suitable container (about 100 mm in diameter and about 180 mm in height) of about 500 mL, and place it on a high-speed dispersing machine base On, fix with clips, start the dispersant (the stirring head is toothed disc type, about 40mm in diameter), adjust the speed at 2500r / min, disperse for 0.5h, then filter, and wash the residue on the inner wall of the container into the filter with tap water , Rinse the filter screen with tap water, dry all the precipitates, calculate the mass percentage of the precipitates, and measure the above experiment 3 times in parallel; observe whether the emulsion break...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com