Preparation method of cardanol triblock polyether

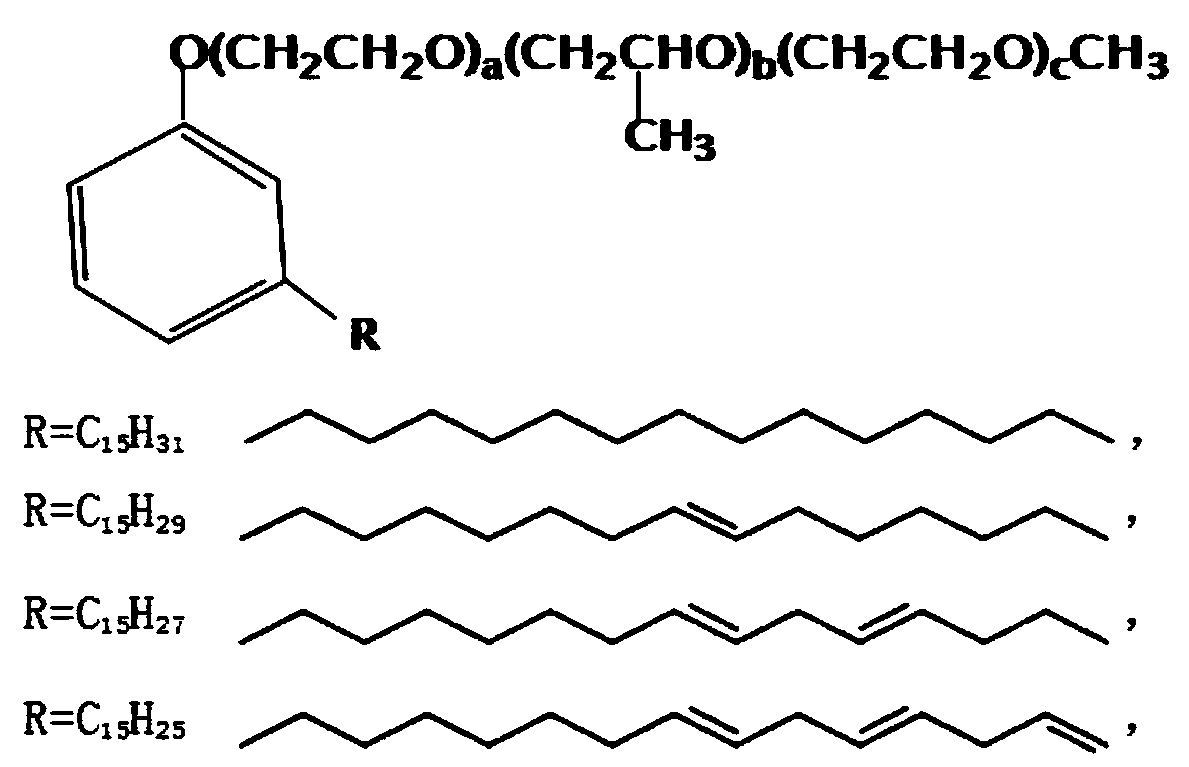

A cardanol and polyether technology is applied in the field of preparation of cardanol tri-polyether, which can solve the problems of high hazard and achieve the effects of low cost, wide adjustable range and excellent low-foaming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of cardanol tri-block polyether, comprising the following steps:

[0020] 1) Clean the reaction kettle with distilled water until it is clean, dry the reaction kettle, and check that the related valves and equipment of the reaction kettle are normal;

[0021] 2) Inhale 400-500 parts of cardanol and 1-5 parts of basic catalyst into the reaction kettle, slowly pull vacuum and heat up to 120°C, dehydrate for 1 hour, fill with nitrogen, and then vacuumize, and then raise the temperature to 140°C ℃;

[0022] 3) Press the measured ethylene oxide ethylene oxide feeder into the reaction kettle in a liquid state with nitrogen, so that the pressure in the kettle reaches 0.1-0.2MPa. After the reaction starts, the temperature rises and the pressure begins to drop, and continue to feed residual ethylene oxide;

[0023] 4) The temperature is 145-155°C, and the pressure is 0.2-0.3 MPa. When all the ethylene oxide is added, until the pressure no longer drops, acc...

Embodiment 1

[0027] raw material

Embodiment 2

[0029] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com