Preparation of modified burdock polysaccharide and application of modified burdock polysaccharide to reactive dye dyeing

A burdock polysaccharide, modified technology, applied in the field of dyeing, can solve the problems of not achieving color fastness to washing and color fastness to wet rubbing, unsatisfactory color fastness to wet rubbing, harming human health, etc., and achieves low cost and easy preparation The process is easy to operate, and the effect of color fixation is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

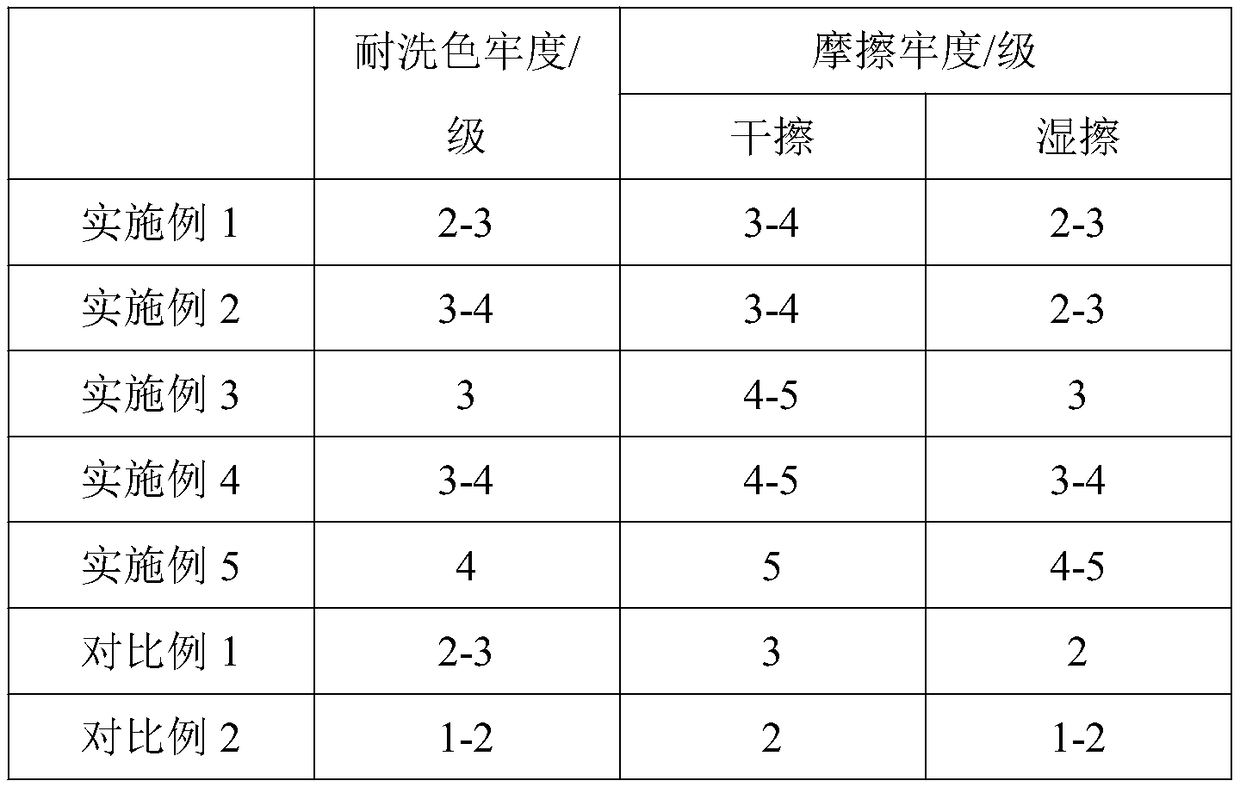

Examples

Embodiment 1

[0024] (1) Vacuum-dry the burdock at 70°C for 4 hours, then crush it with a pulverizer to pass through a 40-mesh sieve, and dry the burdock powder at 60°C for 12 hours for later use;

[0025] (2) Take the dried burdock powder in the reactor, add 1wt% sodium hydroxide solution, control the solid-liquid ratio to 1:40, and the solid-liquid ratio unit is g / mL, heat up to 60°C, and extract for 8 hours;

[0026] (3) Filter the extract in step (2), take the supernatant and adjust the pH value to 3.0 with hydrochloric acid, then centrifuge at 4000r / min for 20min, and collect the supernatant;

[0027] (4) Concentrate the supernatant under reduced pressure at 60°C to one-half of the original volume, then mix the concentrate with 90wt% ethanol solution at a ratio of 1:1, place at -4°C for 12h, and precipitate out;

[0028] (5) Centrifuge the supernatant after the precipitate precipitated in step (4), centrifuge at 4000r / min for 20min, collect the precipitate, and dry it at 60°C to consta...

Embodiment 2

[0032] (1) Vacuum-dry the burdock at 70°C for 4 hours, then crush it with a pulverizer to pass through a 40-mesh sieve, and dry the burdock powder at 60°C for 12 hours for later use;

[0033] (2) Take the dried burdock powder in the reactor, add 1wt% sodium hydroxide solution, control the solid-liquid ratio to 1:30, and the solid-liquid ratio unit is g / mL, heat up to 90°C, and extract for 4 hours;

[0034] (3) Filter the extract in step (2), take the supernatant and adjust the pH value to 3.0 with hydrochloric acid, then centrifuge at 4000r / min for 20min, and collect the supernatant;

[0035] (4) Concentrate the supernatant under reduced pressure at 60°C to one-half of the original volume, then mix the concentrate with 90wt% ethanol solution at a ratio of 1:1, place at -4°C for 12h, and precipitate out;

[0036] (5) Centrifuge the supernatant after the precipitate precipitated in step (4), centrifuge at 4000r / min for 20min, collect the precipitate, and dry it at 60°C to consta...

Embodiment 3

[0040] (1) Vacuum-dry the burdock at 70°C for 4 hours, then crush it with a pulverizer to pass through a 40-mesh sieve, and dry the burdock powder at 60°C for 12 hours for later use;

[0041] (2) Take the dried burdock powder in the reactor, add 1wt% sodium hydroxide solution, control the solid-liquid ratio to 1:38, and the solid-liquid ratio unit is g / mL, heat up to 70°C, and extract for 7 hours;

[0042] (3) Filter the extract in step (2), take the supernatant and adjust the pH value to 3.0 with hydrochloric acid, then centrifuge at 4000r / min for 20min, and collect the supernatant;

[0043] (4) Concentrate the supernatant under reduced pressure at 60°C to one-half of the original volume, then mix the concentrate with 90wt% ethanol solution at a ratio of 1:1, place at -4°C for 12h, and precipitate out;

[0044] (5) Centrifuge the supernatant after the precipitate precipitated in step (4), centrifuge at 4000r / min for 20min, collect the precipitate, and dry it at 60°C to consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com