Water permeable concrete

A permeable concrete and cementitious material technology, which is applied in the field of concrete processing, can solve the problems of low freeze-thaw resistance, poor bearing capacity, and small cohesive force, and achieve excellent frost resistance, good durability, and improved frost resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

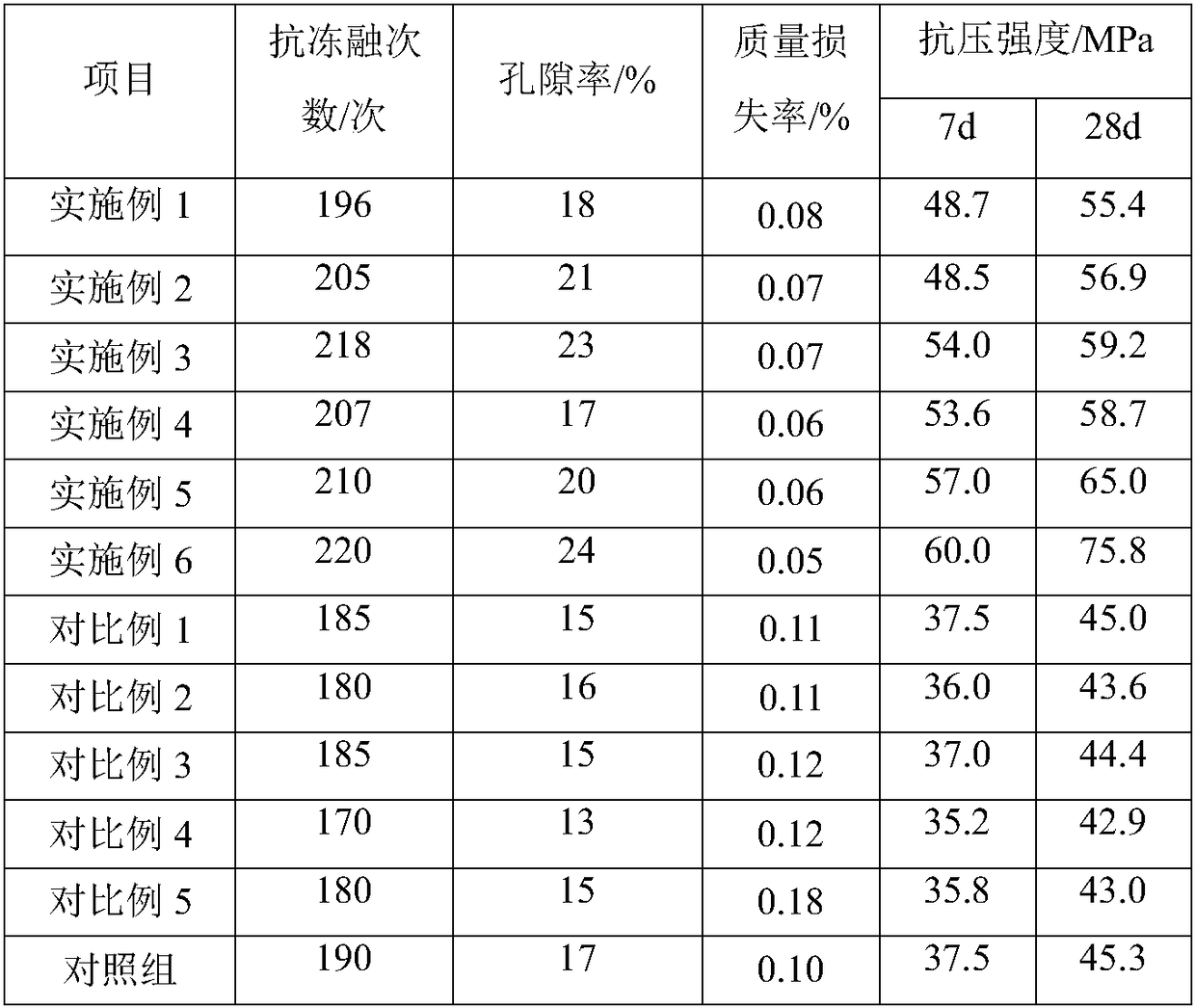

Examples

Embodiment 1

[0029] A permeable concrete, comprising the following raw material components in parts by weight: 216kg of cement, 84kg of fly ash, 1000kg of stones, 10kg of fly ash floating beads, 1kg of sodium alkylsulfonate, 5kg of polycarboxylate high-performance water reducer, steel Fiber 3kg, water 100kg, polyacrylonitrile fiber 6.67kg and dura fiber 3.33kg. Wherein, the length of the dura fiber and the length of the steel fiber are both greater than the length of the nylon fiber.

Embodiment 2

[0031]A permeable concrete, comprising the following raw material components by weight: 224kg of cement, 96kg of fly ash, 1100kg of stones, 15kg of fly ash floating beads, 2kg of sodium alkylbenzene sulfonate, 7kg of polycarboxylate high-performance water reducer, Steel fiber 3.5kg, water 110kg, polyacrylonitrile fiber 9.4kg and dura fiber 5.6kg. Wherein, the length of the dura fiber and the length of the steel fiber are both greater than the length of the nylon fiber.

Embodiment 3

[0033] A permeable concrete, comprising the following raw material components by weight: 231.2kg of cement, 108.8kg of fly ash, 1150kg of stones, 18kg of fly ash floating beads, 2kg of sodium alkylsulfonate, 2kg of sodium alkylbenzenesulfonate, poly Carboxylic acid high-performance water reducing agent 8.5kg, steel fiber 3.8kg, water 118kg, polyacrylonitrile fiber 9.4kg and dura fiber 7.6kg. Wherein, the length of the dura fiber and the length of the steel fiber are both greater than the length of the nylon fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com