Solidification method for hydraulic reclamation silt quilt

A curing method and technology with chemical properties, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. The effect of fast consolidation and high engineering strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

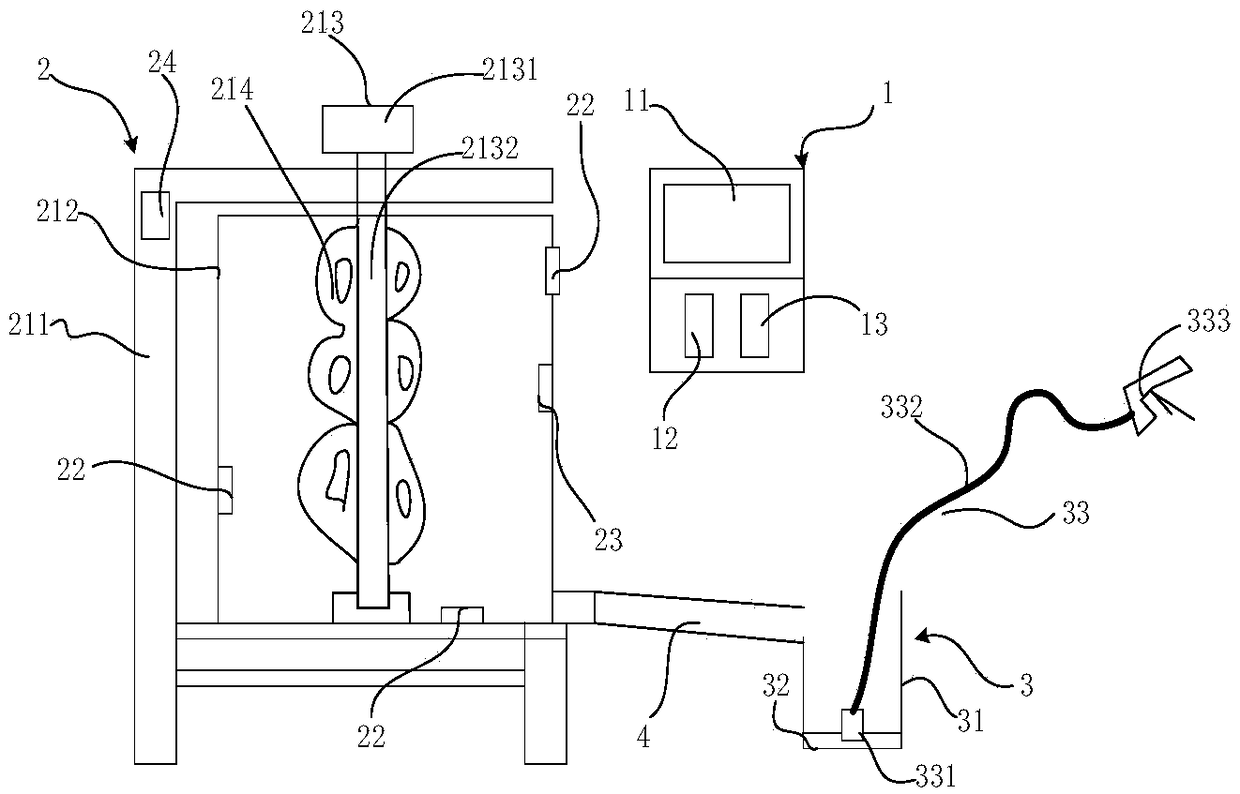

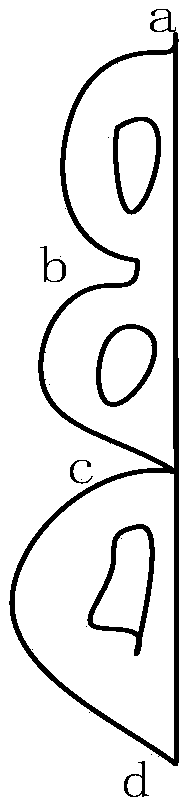

Method used

Image

Examples

Embodiment 1

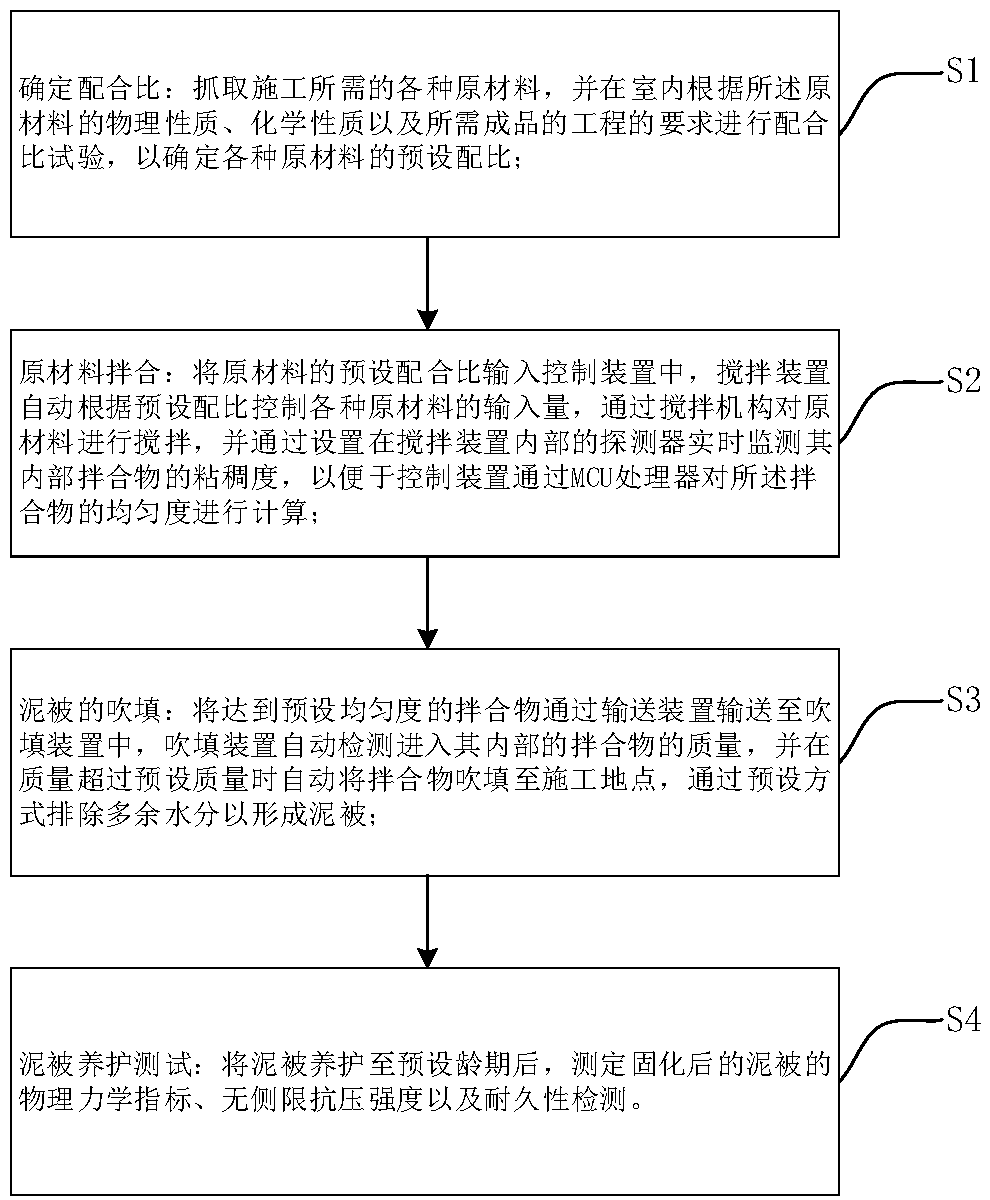

[0090] Embodiment 1, a kind of solidification method of dredging mud quilt, its scheme and steps are as follows:

[0091] (1) Mixing ratio: silt 100, water 200, alkali slag 10, curing agent 15.9.

[0092] (2) Implementation steps: material entry - detection - sludge, alkali slag, and curing agent are stirred in sequence - dredging mud quilt - vacuum water absorption - maintenance - test.

[0093] (3) Indicators: 28-day compressive strength of 2.88 MPa, cohesion of 65 kPa, and internal friction angle of 22 degrees.

Embodiment 2

[0094] Embodiment 2, a kind of technical example of novel iron tailings concrete manufacture, its scheme and steps are as follows:

[0095] (1) Mixing ratio: sludge 100: water 10: alkali slag 5.6: curing agent 10.6.

[0096] (2) Implementation steps: material entry - detection - iron tailings, alkali slag, curing agent stirring in turn - transportation, filling mud quilt - drainage - maintenance - testing.

[0097] (3) Indicators: 28-day compressive strength of 1.12 MPa, cohesion of 45 kPa, internal friction angle of 18.5 degrees.

Embodiment 3

[0098] Embodiment 3, a kind of technical example of novel iron tailings concrete manufacture, its scheme and steps are as follows:

[0099] (1) Mixing ratio: sludge 100: water 150: alkali slag 4.5: curing agent 7.5, dredging mud is used as sea reclamation material.

[0100] (2) Implementation steps: material entry - detection - stirring machinery in place - alkali slag, curing agent stirring slurry - stirring, wet spraying - maintenance - testing.

[0101] (3) Index: 28-day compressive strength of 0.91 MPa.

[0102] Obviously, it can be drawn that the present invention has the following advantages and technical effects: 1) the technology of the present invention can fully embody waste utilization and resource regeneration: industrial waste residues such as alkali slag, slag, fly ash are all rare resources, and Make full use of local silt resources; 2), the technology of the present invention is beneficial to environmental protection: my country's government and enterprises hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com