A magnetically conductive plate for positioning separable transformers

A magnetic plate and transformer technology, applied in the direction of transformers, transformer/inductor magnetic cores, transformer/inductor components, etc., can solve problems such as low reliability, complex equipment, foreign object interference, etc., to achieve high reliability, The effect of high discrimination and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

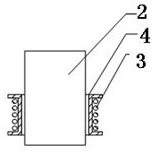

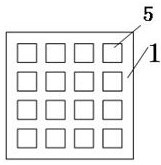

[0028] Example 1: as Figure 4 and 5 As shown, the coil 3 wound on the magnetic conductor 2 includes a row coil 32 and a column coil 31, the row coil 32 is located above, the column coil 31 is located below, N1+N2 electromotive force detection circuits 6, and the electromotive force detection circuit 6 uses a voltage Or a current sensor, the coils 31 of the two columns of the magnetizers located in the same column are connected in series, and then connected to an electromotive force detection circuit 6, and the coils 32 of the two columns of magnetizers located in the same row are connected in series in sequence, and then connected to an electromotive force detection circuit 6.

[0029] The working method is as follows: when the separable transformer generates an alternating magnetic field, an alternating magnetic flux will be generated on the magnetic conductor 2 that is approaching or contacting, and the row coil 32 and the column coil 31 will generate an induced electromoti...

example 2

[0030] Example 2: as Image 6 As shown, the coils 3 wound on the magnetic conductor 2 can be a group, N1+N2 electromotive force detection circuits 6, the electromotive force detection circuit 6 adopts a voltage or current sensor, and the coils 3 of the magnetic conductor 2 in the same column / row are connected in series with For the diodes 7, all the series branches are connected in parallel to the electromotive force detection circuit 6, and the diodes 7 connected in series with the coils 3 of the magnetizers 2 in the same column / row have the same conduction direction.

[0031] The working method is as follows: when the separable transformer generates an alternating magnetic field, an alternating magnetic flux will be generated on the magnetic conductor 2 that is approaching or contacting, and the coil 3 will generate an induced electromotive force. When the voltage or current sensor is detected in the row or column, the row or column where the induced voltage or current is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com