Measuring device for wire protection sleeve cutting

A wire protection and sleeve technology, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve problems such as affecting the efficiency of cutting and blanking operation, protecting the sleeves from being entangled together, and size cutting errors, etc., to avoid size Cropping error, improved yield, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

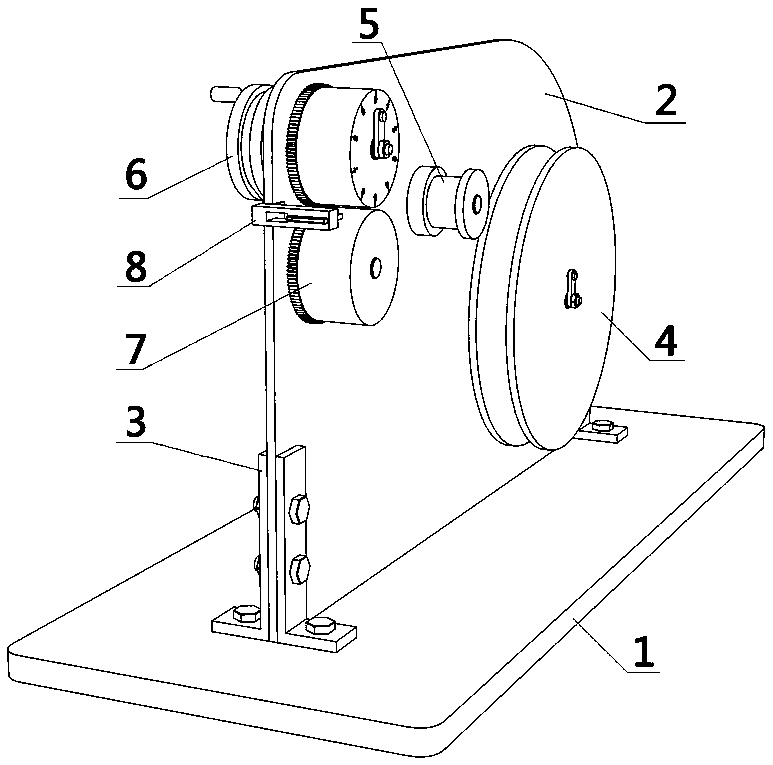

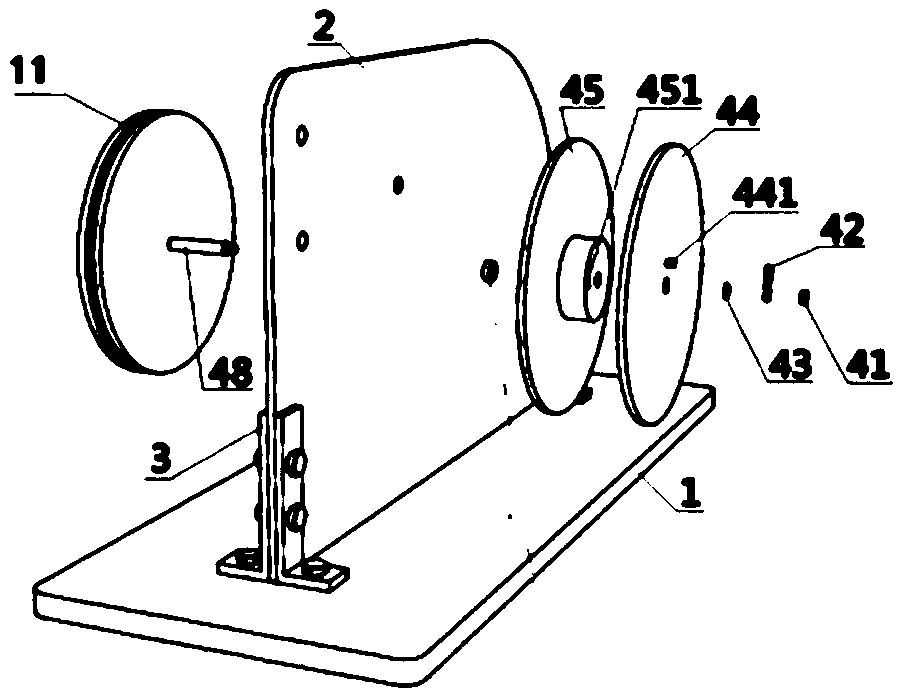

[0031] see figure 1 and figure 2 , a measuring device for cutting a wire protective sleeve includes a supporting mechanism, a roll material fixing mechanism, a clamping measuring mechanism and a transmission mechanism.

[0032] see figure 1 , the support mechanism includes a bottom plate 1 and an upright support plate 2, and the two sides of the bottom of the support plate 2 are fixedly installed on the bottom plate 1 through two pairs of L-shaped mounting plates 3 respectively. The coil material fixing mechanism and the clamping and measuring mechanism are fixedly installed on one side of the support plate 2 , and the transmission mechanism is fixedly installed on the other side of the support plate 2 .

[0033] see figure 2 , Transmission mechanism comprises large pulley 11, small pulley 12 and transmission belt 9, and transmission belt 9 straddles large pulley 11 and small pulley 12.

[0034] see figure 1 and image 3 , The coil fixing mechanism includes a feeding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com