Embedded spindle system abnormal state intelligent detection and information push device

An abnormal state and information push technology, applied in the direction of measuring/indicating equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of adding equipment, insufficient signal, no explanation or report found, etc., to achieve enhanced robustness , Eliminate misjudgment, reduce the effect of judgment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The embodiments of the present invention are described in detail below: the following embodiments are implemented on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are provided. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

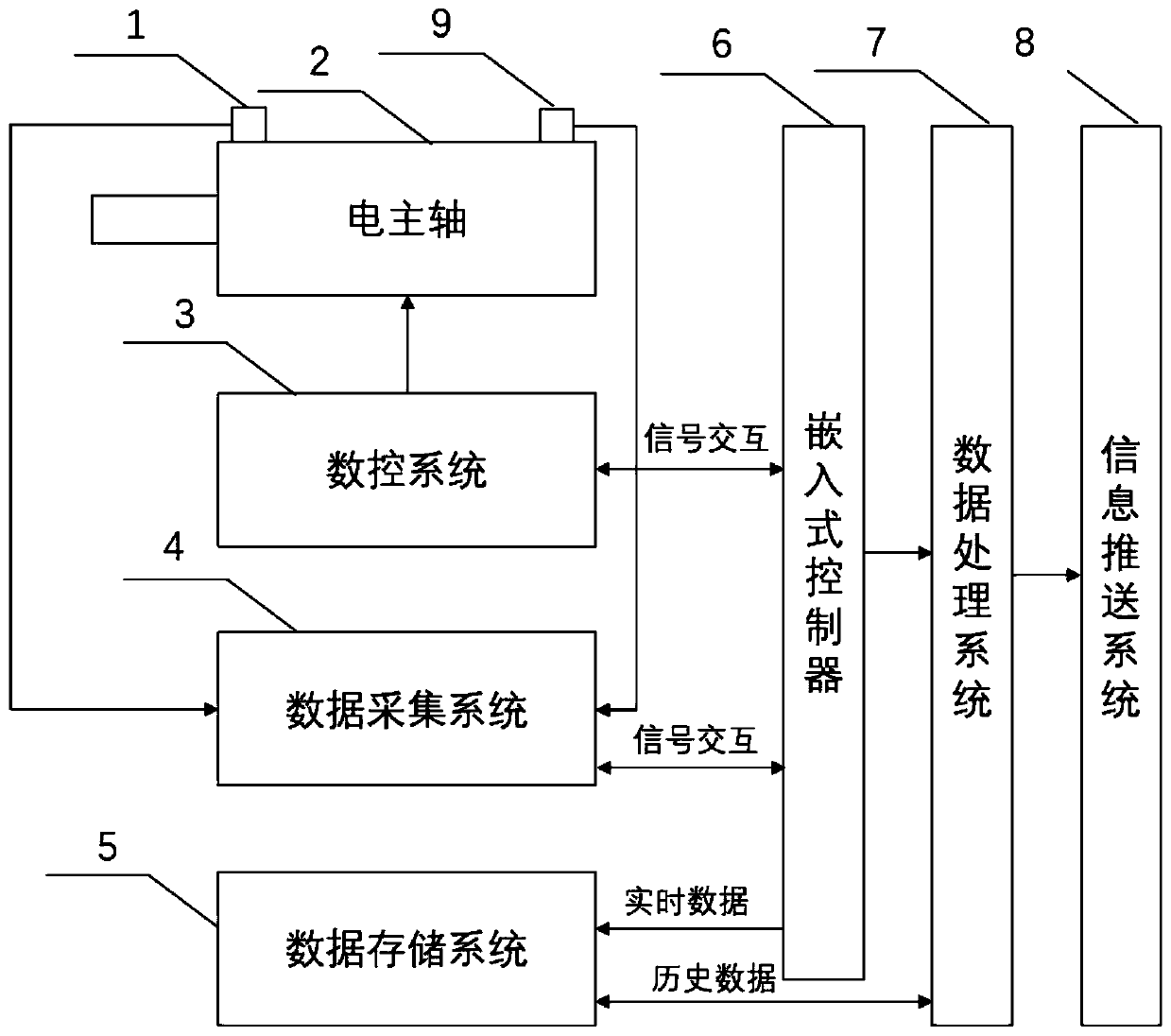

[0052] refer to figure 1As shown, a structural schematic diagram of an embodiment of an embedded spindle system abnormal state intelligent detection and information push device, which includes vibration sensors 1 and 9, temperature sensors, numerical control system 3, data acquisition system 4, data storage system 5, embedded Type controller 6, data processing system 7, information push system 8, a vibration sensor is respectively set at the front and rear bearings of the electric sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com