Full working condition sealing test device

A technology of sealing test and full working conditions, which is applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problem that the sealing test device cannot simultaneously simulate the working conditions of the sealing device of the aeroengine, and cannot truly reflect the sealing The actual situation of the device and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

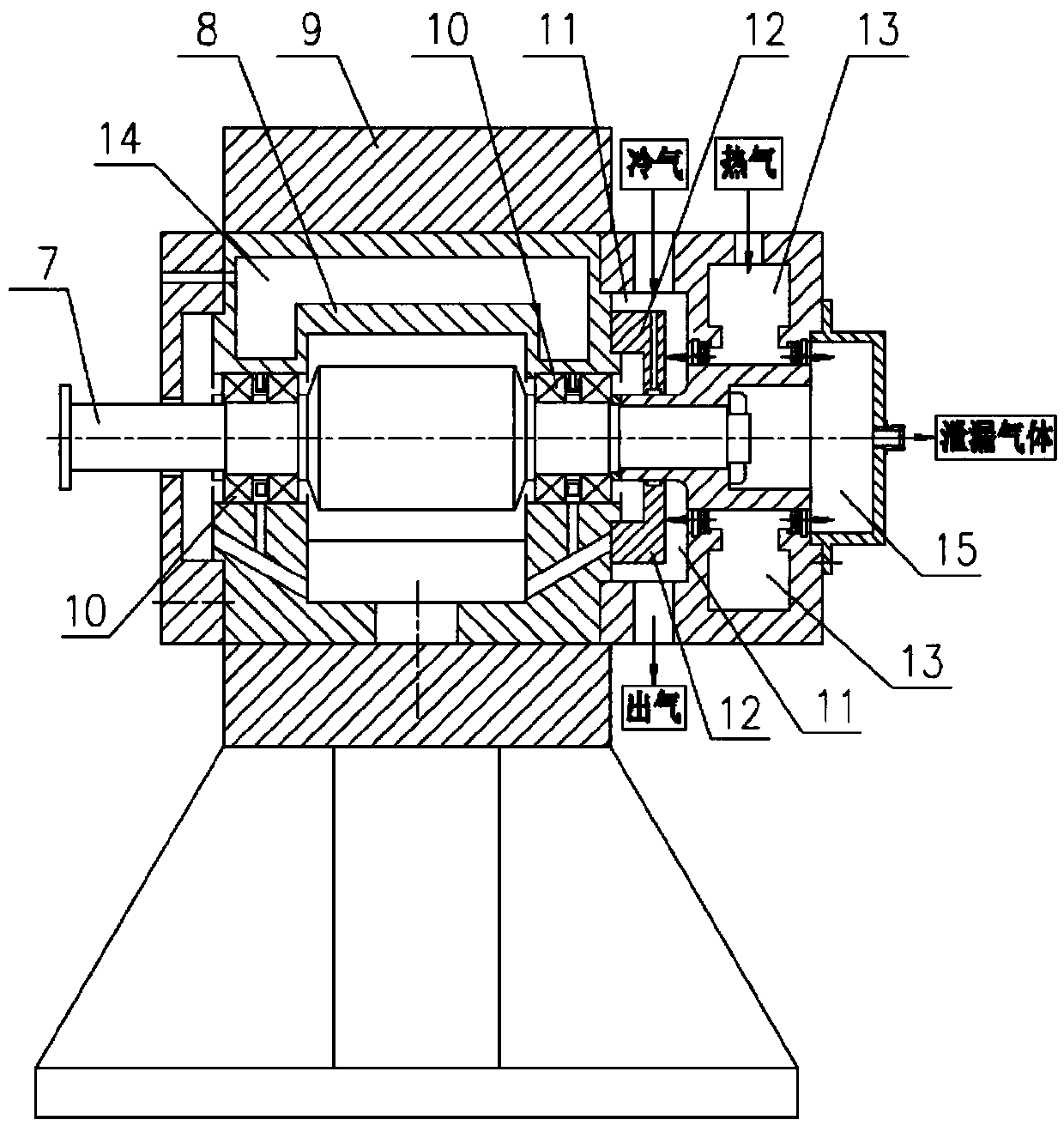

[0025] see figure 1 , a preferred embodiment of the present invention provides a test bench, including a rotor 7, a bearing 10 for supporting the rotor 7, a bearing seat 8 and a support 9; Chamber 13 communicates with air outlet chamber 15 and exhaust duct 11 respectively; the channel connected between high pressure chamber 13 and air outlet chamber 15 is the placement position of the sealed test piece, which is used to place the test piece for testing, and the high pressure chamber 13 is connected with exhaust duct 11 The channel is the place where the accompanying test piece is placed, and is used to place the accompanying test piece. The exhaust channel 11 communicates with the cold air passage, and a hot air sealing ring 12 is provided between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com