Automobile pedal bracket welding tool

A technology for welding tooling and automobile pedals, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to position alone, increase production costs, and poor welding consistency, so as to facilitate individual adjustment, Low-cost, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

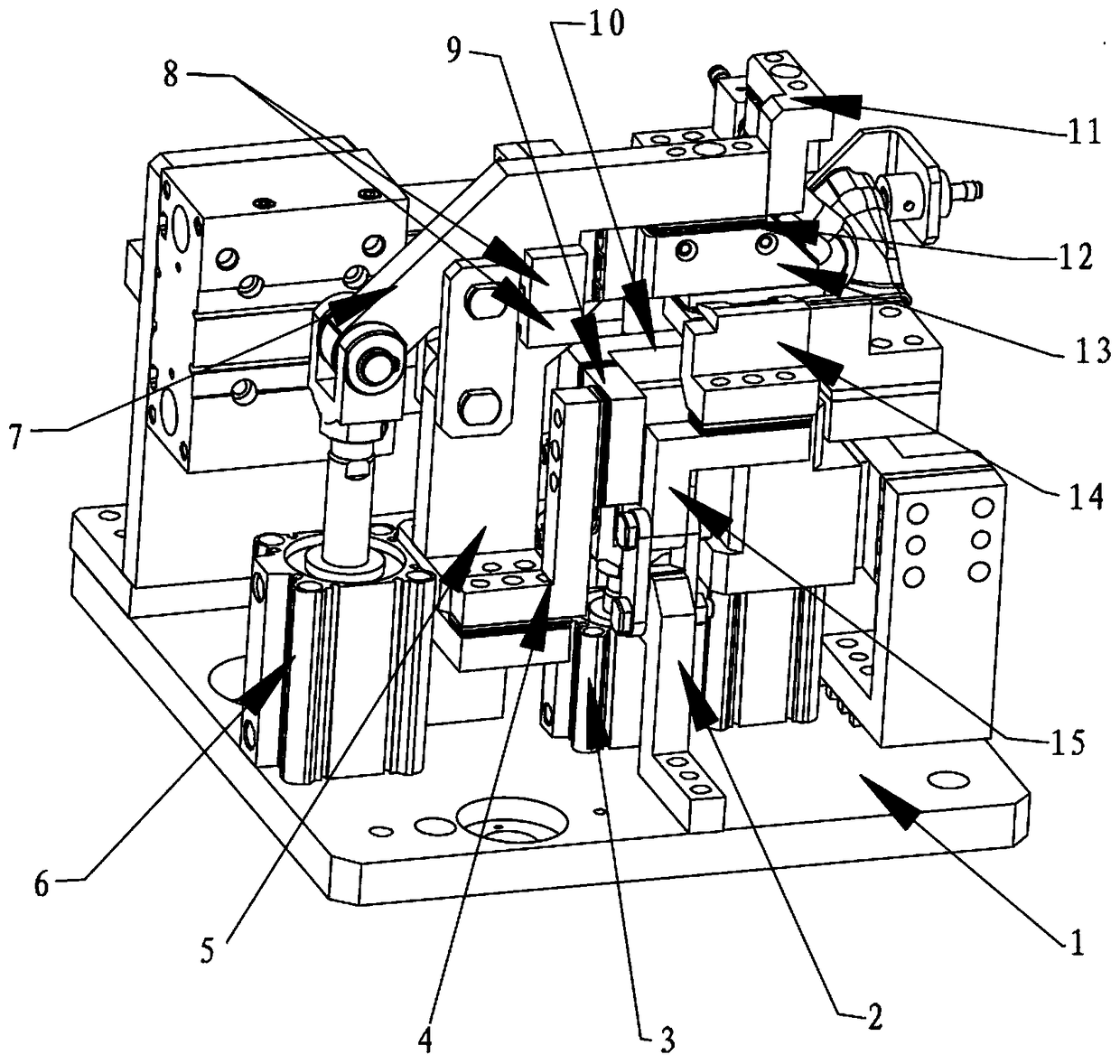

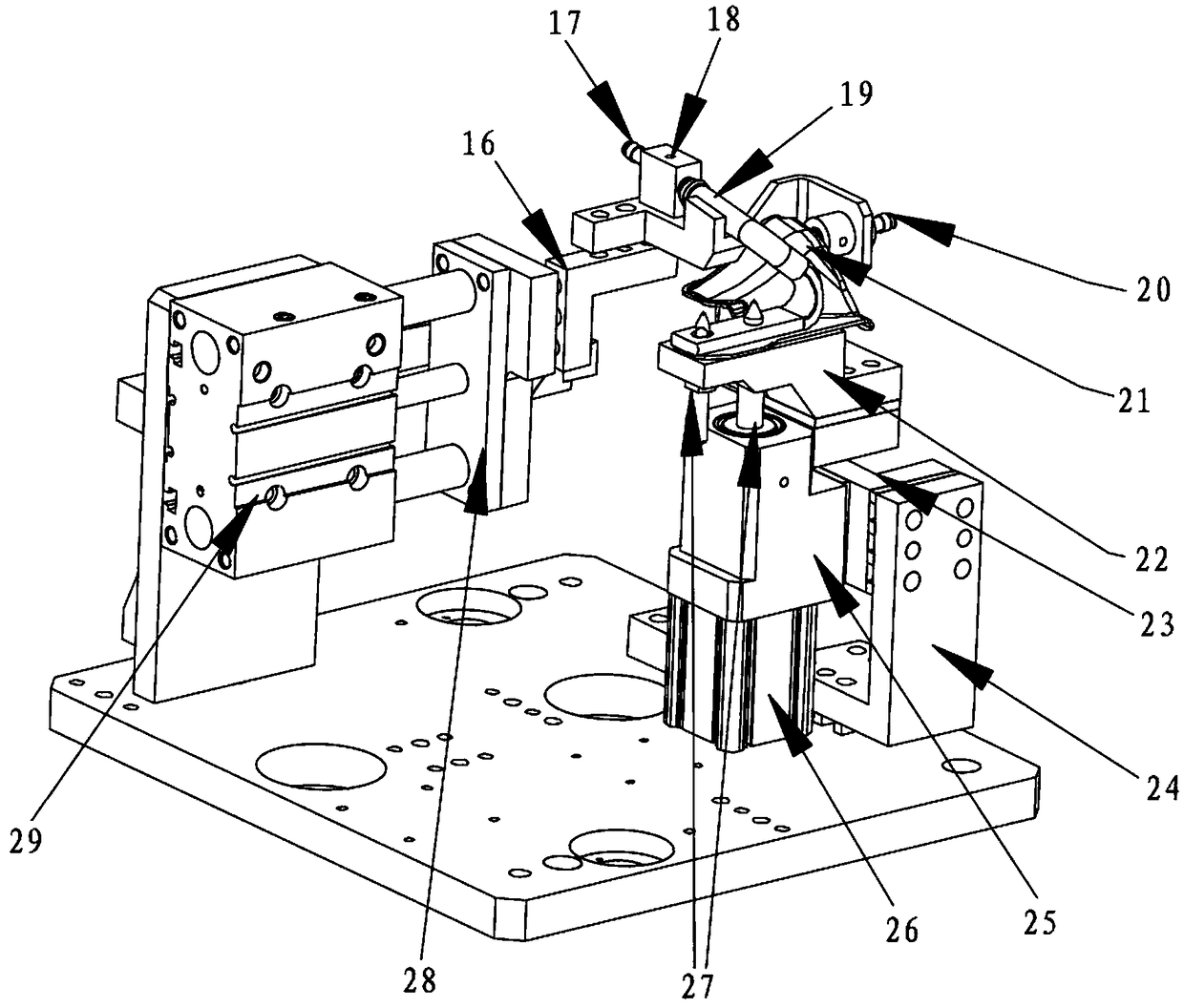

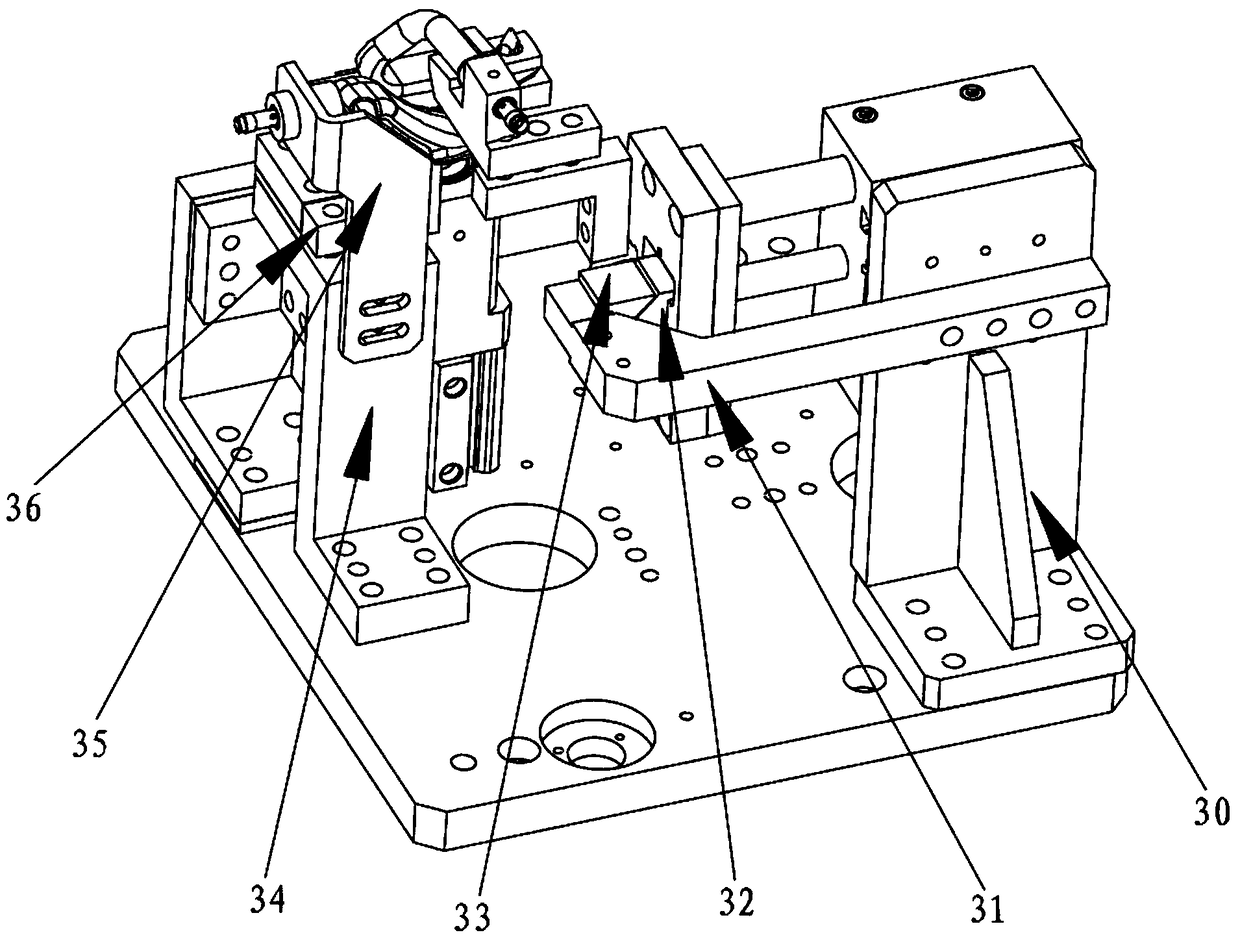

[0021] see figure 1 , figure 2 and image 3 , the best embodiment of the present invention, a kind of automobile pedal bracket welding equipment, including fixture bottom plate 1, stamping parts pressing mechanism, steel bar pressing mechanism, welding slag protective copper skin 13, limit mechanism, positioning mechanism, stamping parts Leakage detection sensor 20 and reinforcing bar leakage detection sensor 17.

[0022] The stamping part pressing mechanism includes an L-shaped connecting block 2, a stamping part pressing cylinder 3, a first connecting block 15 and a stamping part pressing head 14, and the L-shaped connecting block 2 and the stamping part pressing cylinder 3 are respectively fixed on the bottom plate of the fixture 1, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com