Washing system for trough type sheet nut

A thin-plate nut and cleaning system technology, which is applied in the mechanical field, can solve the problems of low cleaning efficiency, high material consumption, and limited cleaning capacity of groove-shaped thin-plate nuts, and achieve good cleaning, improved efficiency, and strong cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

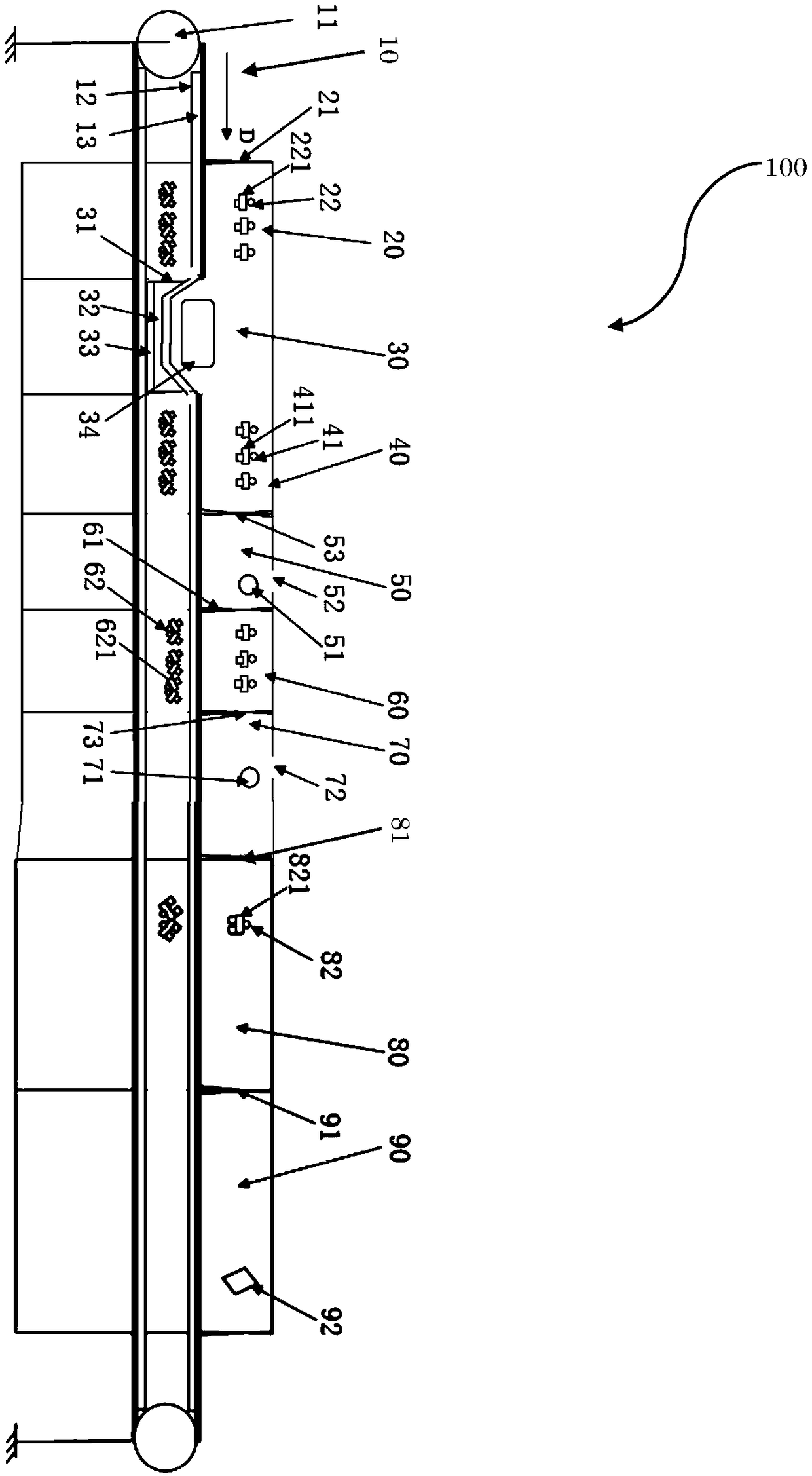

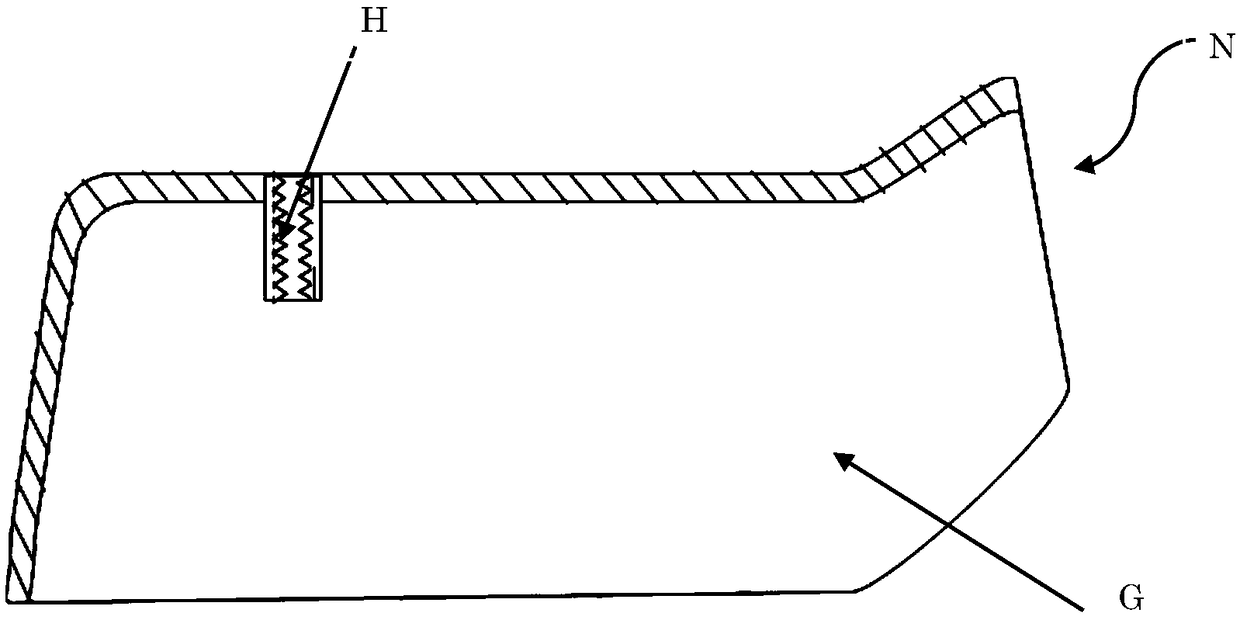

[0023] Such as figure 1 , figure 2 As shown, the trough-type sheet nut cleaning system 100 includes: a housing, a transmission part 10, a cleaning liquid spray part 20, an ultrasonic cleaning part 30, a first anti-rust liquid spray part 40, a first high-temperature drying part 50, a first Two anti-rust liquid spraying parts 60, the second high-temperature drying part 70, anti-rust spraying part 80 and blowing part 90 and the control part connected with the above parts respectively, the control part is used to control the operation of each part connected with it.

[0024] The shell is in the shape of a rectangular parallelepiped box, and two openings of the same shape and size are respectively arranged on the side surfaces of the two ends of the shell.

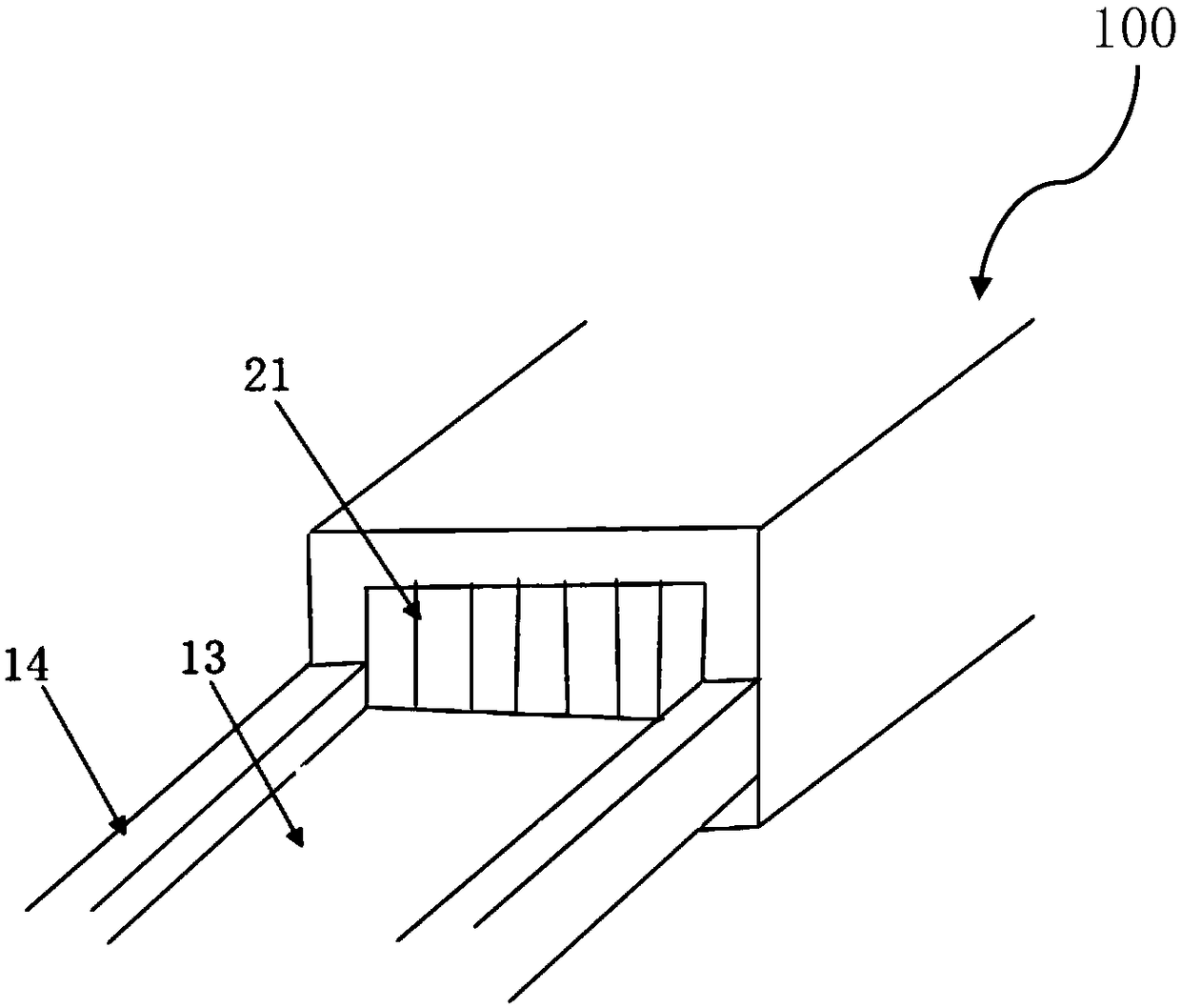

[0025] The transmission part 10 includes a frame, a sprocket 11, a guide rail 12, a conveyor belt 13 and a guide plate 14.

[0026] According to the cleaning sequence of groove-shaped thin plate nuts, there are connected cle...

Embodiment 2

[0082] The other structure of this embodiment is the same as that of Embodiment 1. The difference is that the cleaning liquid spray unit 22 and the first anti-rust liquid spray unit 41 are liftable structures. The cleaning infusion pipe of the part 20 and the antirust infusion pipe at the first antirust liquid spraying part 40 are all provided with a threaded rod perpendicular to the conveyor belt 13, and the threaded rod is arranged in the opposite direction of the conveyor belt 13, and the surface of the threaded rod is threaded. It meshes with the nut that is movably connected to the motor. The motor is set on the shell and electrically connected to the outside. Start the motor to drive the nut to rotate. At this time, the nut and the threaded rod form a screw nut system of the fixed nut to control the motor. Forward rotation or reverse rotation makes the threaded rod pull the cleaning infusion pipe to realize the lifting of the cleaning liquid spray unit 22 , and similarly ...

Embodiment 3

[0085] The other structure of this embodiment is the same as that of Embodiment 2, the difference is that the cleaning liquid nozzle 221 and the anti-rust liquid nozzle 411 are both rotatable structures, and the specific structure of the rotatable structure is that each cleaning liquid nozzle 221 and each anti-rust liquid nozzle The rust liquid spray nozzles 411 are respectively coaxially connected with the output shaft of a micro motor. The micro motor is arranged on the cleaning infusion tube and the first anti-rust liquid infusion tube and is electrically connected to the outside. The micro motor is started from the outside to make each cleaning liquid The spray head 221 or each antirust liquid spray head 411 realizes the rotation in a specific plane parallel to the conveyor belt 13 .

[0086] Rotate the cleaning liquid nozzle 221 or the anti-rust liquid nozzle 411 according to actual work requirements to adjust the spraying area of the cleaning liquid nozzle 221 or the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com