Scrape coating device applied to preparation of perovskite batteries and thin film preparation method

A perovskite battery and equipment technology, applied in coatings, devices for coating liquid on the surface, etc., to achieve the effects of simple structure, uniformity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

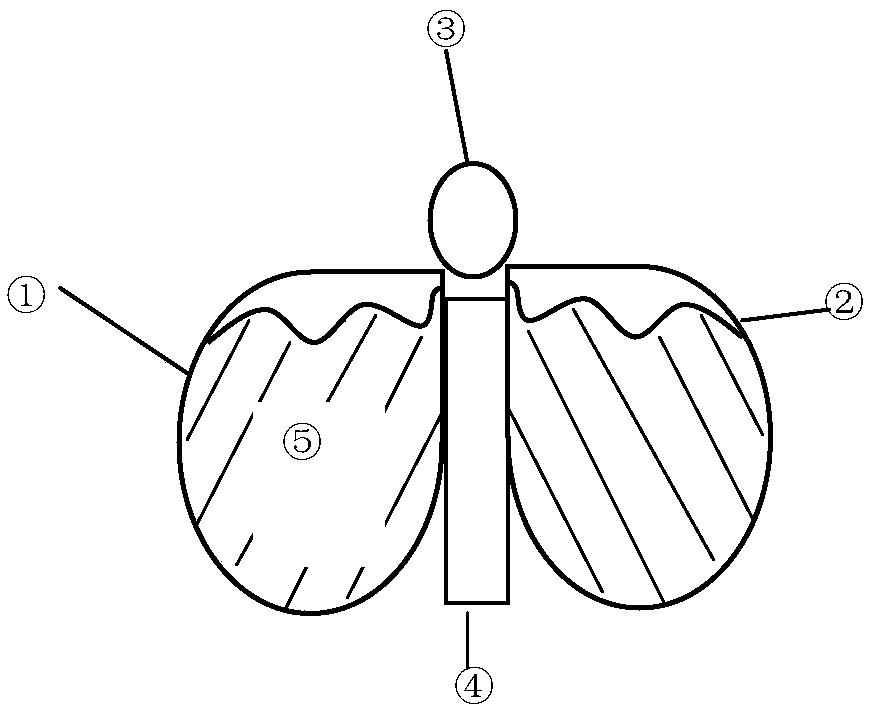

[0055] A kind of scraping equipment applied to the preparation of perovskite batteries, mainly used for low-concentration film-forming material liquid, which includes a wire rod, a liquid supply device connected to the wire rod, and may also include a mounting bracket and a drive mechanism (such as a drive Motor or drive cylinder, etc.), the wire rod can be installed on the mounting bracket, the driving mechanism is connected with the mounting bracket or the wire rod transmission, and at least makes the wire rod move along the set direction and the set track; the specific structural form of the mounting bracket can be Set according to the specific situation.

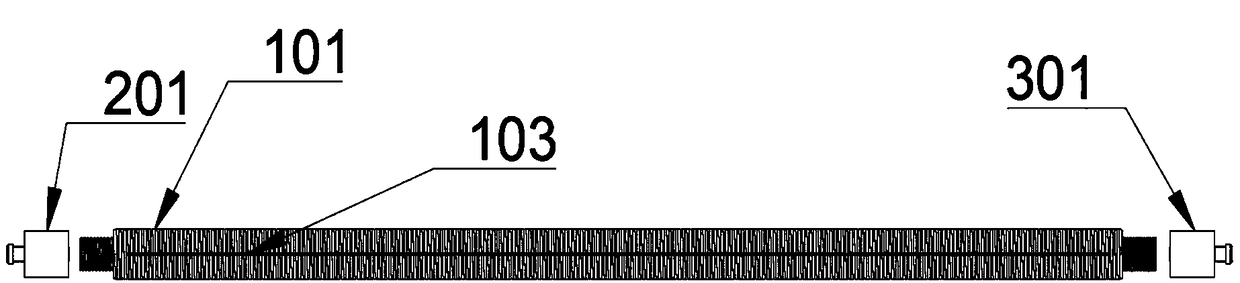

[0056] see Figure 2-Figure 5 , the wire rod includes a wire rod body 101, inside the wire rod body 101 is provided with a liquid storage chamber 102 extending along its axial direction, the liquid storage chamber 102 is used to store the material liquid, and at the same time, the surface of the wire rod body 101 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com