Pure mechanical drive type spray painting robot

A spraying robot and transmission technology, applied in the direction of manipulators, program-controlled manipulators, spraying devices, etc., can solve the problems of low spraying precision requirements of robots, affecting product appearance and spraying efficiency, increasing production and upgrading costs of enterprises, etc., to achieve the goal of building The installation process is simple and light, reducing the explosion-proof area and cost, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

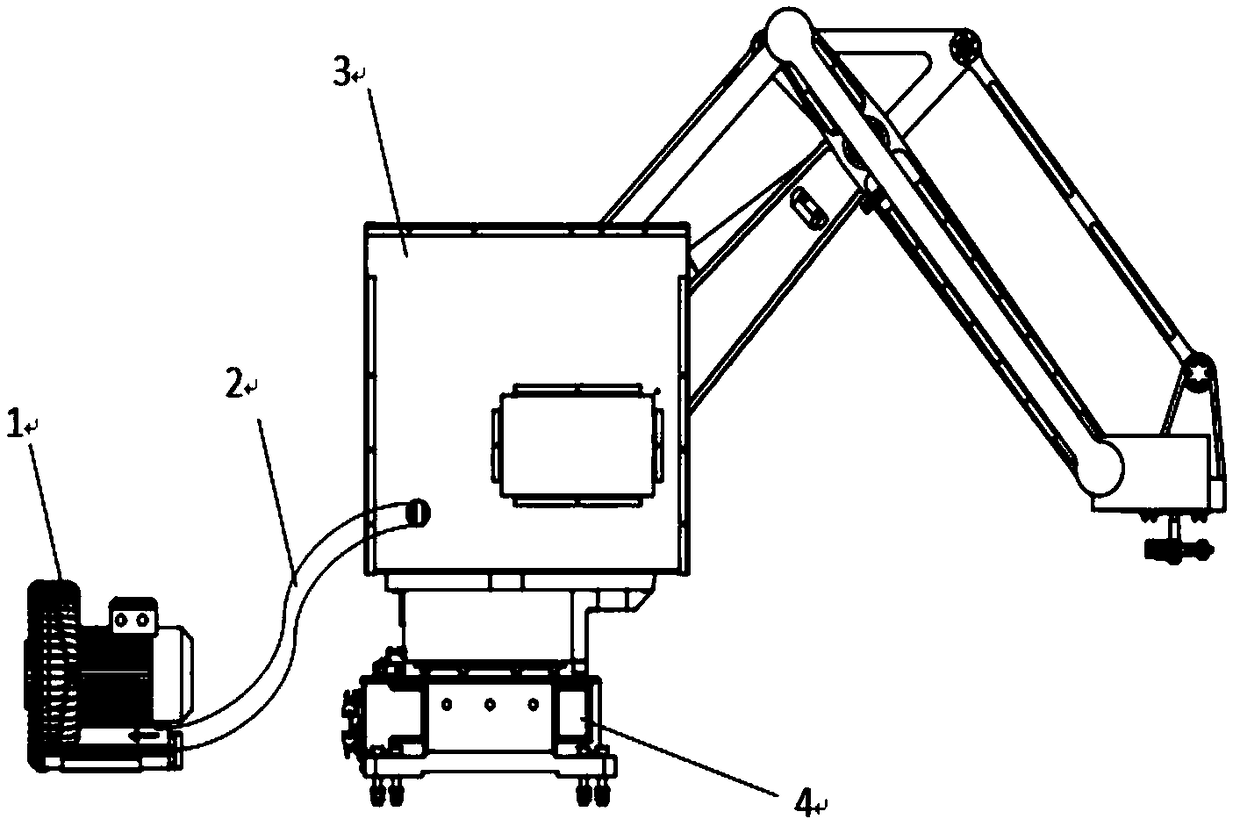

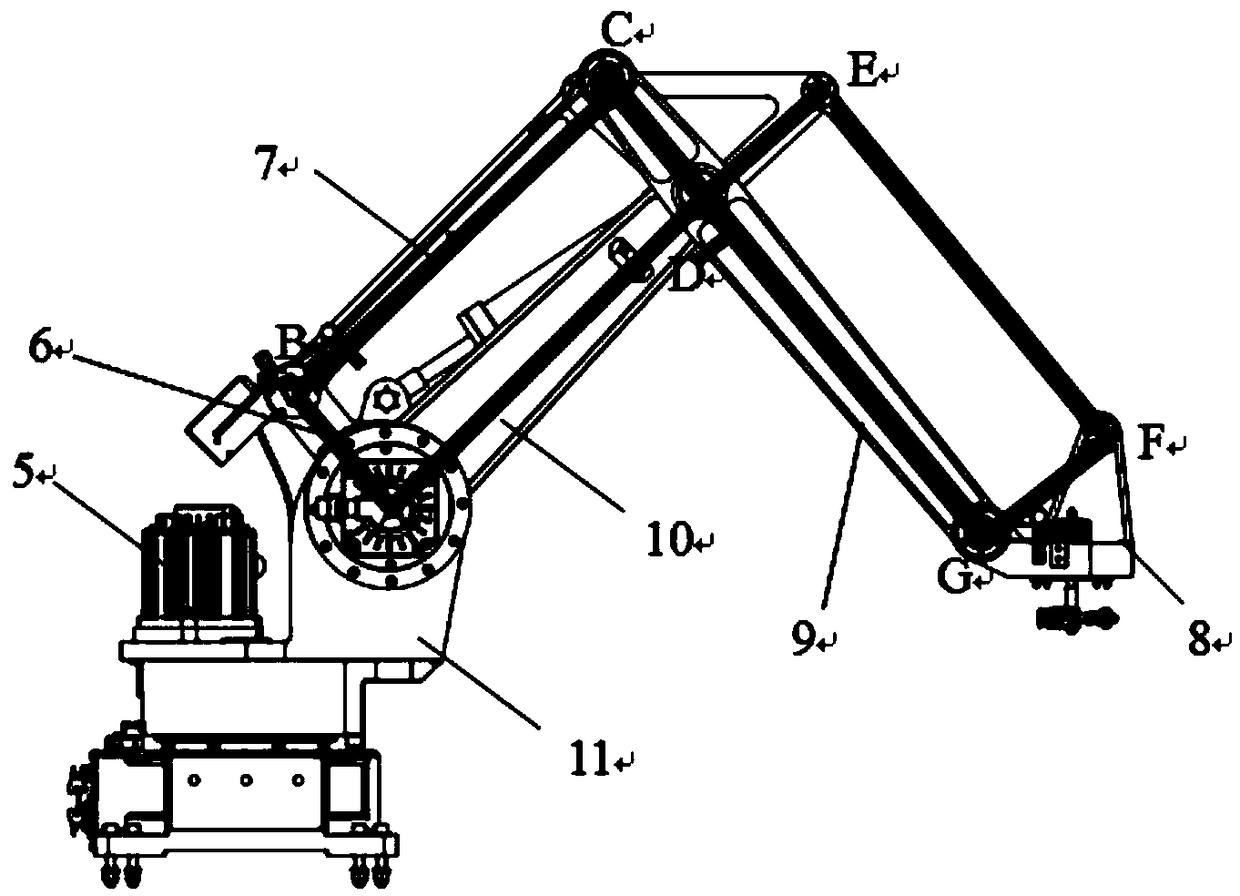

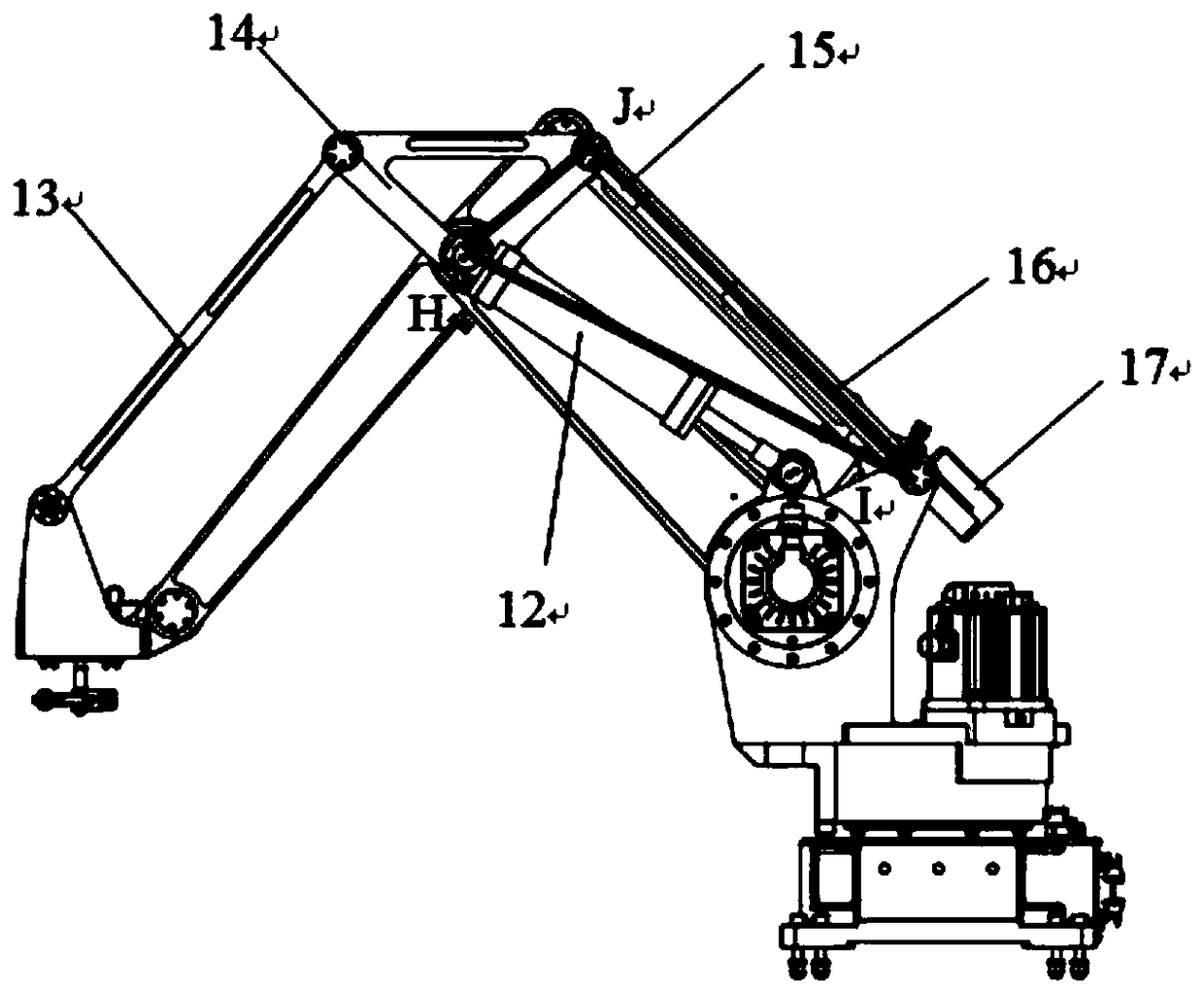

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a purely mechanical transmission spraying robot, which is characterized in that the device includes a five-degree-of-freedom robot and a positive pressure explosion-proof system. The five-degree-of-freedom machine is fixed horizontally on the ground, and the positive pressure explosion-proof system isolates the electrical part of the five-degree-of-freedom machine level from the ambient gas to achieve explosion-proof effects. The five-degree-of-freedom machine includes a fixed base 1, a rotating base 11, a rotating drive device 5, an end mount 8, a spray gun 24, a position adjustment lever group, an attitude adjustment rod group, and a synchronous wheel drive. The rotary drive device 5 includes a servo motor, gears and Cycloidal pinwheel reducer, the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com