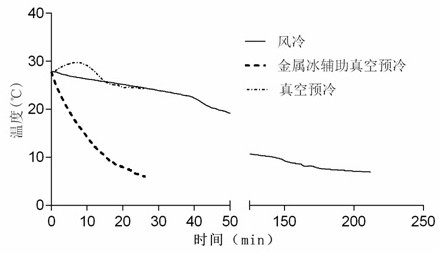

A method of accelerating the precooling rate in the vacuum precooling process of bayberry

A vacuum and pre-cooling technology, which is applied in the fields of freezing/cold storage of fruits/vegetables, food science, fruit and vegetable preservation, etc., can solve the problems of insufficient utilization and inability to complete the temperature drop of bayberry, and achieve reduced water loss and good vacuum Pre-cooling effect, the effect of accelerating the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) The freshly picked Dongkui bayberry should be sent to the laboratory immediately, and the time should not exceed 2 hours. Through the pretreatment of the harvested red bayberry, select the red bayberry with a deep luster, no peculiar smell, a complete sample, a diameter of about 45mm (the average diameter of a larger bayberry), no juice, and no damage. The red bayberry that selects for use is 2kg.

[0033] (2) The reconstituted metal ice is first washed with tap water, and then placed in a cold storage at -18±2°C for processing, and taken out after 2 hours (the central temperature value is -2±2°C), and then put into the mass fraction Soak in 75% low-temperature alcohol for 30s to sterilize. Wherein, the ratio of the composition of the brine in the metal ice in this embodiment is 15% of 95% alcohol, 83% of water and 2% of sodium alginate. The size of metal ice is 50mm. At the same time, the operating conditions of the "metal ice assisted vacuum precooling" in Exam...

Embodiment 2

[0050] Example 2 is similar to Example 1, but the difference is the size of the metal ice side length. In order to form a comparison and determine the optimal size, we selected metal ice with a side length of 60mm and 65mm for comparison. The results are shown in Table 4 Shown: With the increase of the side length of metal ice, the precooling time and water loss rate of bayberry both increase. The above-mentioned results show that the side length of the selected specific metal ice in the patent scope can effectively reduce the water loss rate, precooling time and appearance quality change of red bayberry.

[0051] Table 4 Effects of different metal ice edge lengths on water loss and precooling time of bayberry

[0052]

Embodiment 3

[0054] The operation method of embodiment 3 is the same as that of embodiment 1, the difference is the brine in the metal ice, in order to form a comparison, we have selected various proportions of brine for comparison, such as I, II, and IV in Table 5 and V, while the present embodiment used 15% 95% alcohol, 83% water and 2% sodium alginate (III). The results are shown in Table 4: Different refrigerants will also lead to differences between the results. From the data results in Table 5, it can be speculated that too high or too low sodium alginate and alcohol content will lead to changes in the parameters of the red bayberry pre-cooling process , the proportion range (Ⅲ) of this example can obtain the lowest moisture loss rate and precooling time compared with other proportions. The above five precooling methods had little difference in the change of the corruption rate and appearance quality of bayberry. Simultaneously, the above-mentioned results also show that the selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com