Structure design method of torque motor with low torque fluctuation

A torque motor and torque fluctuation technology, applied in the field of torque motor structure design with low torque fluctuation, can solve problems such as control failure, torque fluctuation, performance degradation, etc., to reduce motor torque fluctuation, reduce cogging torque, The effect of torque curve smoothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below. The embodiments are exemplary and are intended to explain the present invention, but should not be understood as a limitation to the present invention.

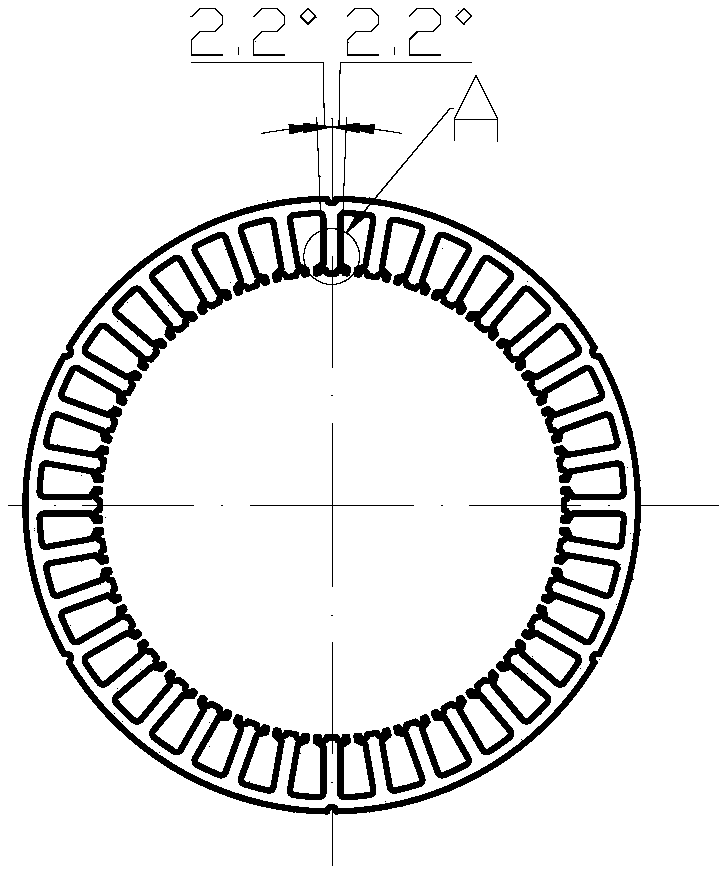

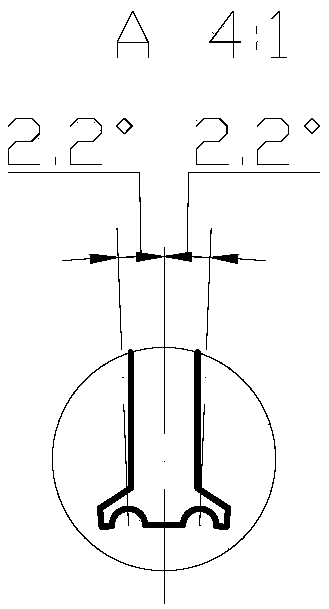

[0025] The stator structure of the motor designed in this embodiment is as figure 1 with figure 2 As shown, in order to minimize the torque fluctuation of the motor, auxiliary slots are opened in the stator teeth of the motor. The principle of opening auxiliary slots is equivalent to increasing the number of fundamental wave cycles of cogging torque. The new cogging torque of the auxiliary slot has an effect on the cogging torque of the original slot, making the total cogging torque amplitude reduce. The opening of auxiliary grooves in the teeth also increases the equivalent air gap, which is also conducive to reducing the cogging torque.

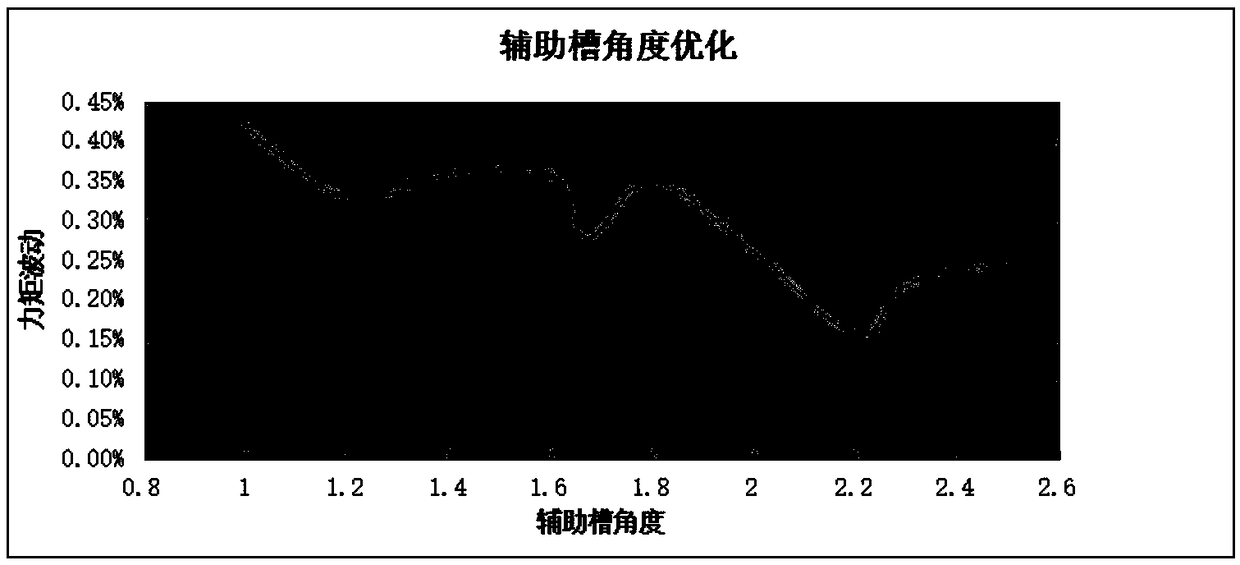

[0026] The following is a design description from three aspects of the number of auxiliary slots and the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com