Crank type piston pneumatic engine apparatus

A pneumatic engine, crank technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of affecting the working efficiency of the system, unfavorable large power output, large torque fluctuation rate, etc., to ensure reliability and stability, Improved energy efficiency and less torque fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

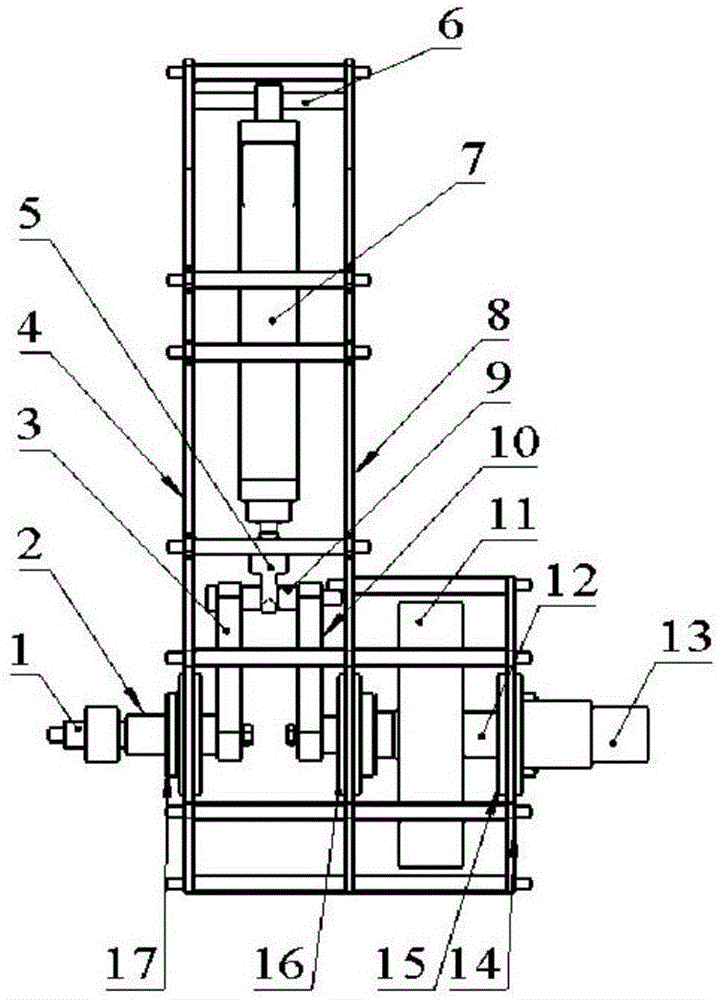

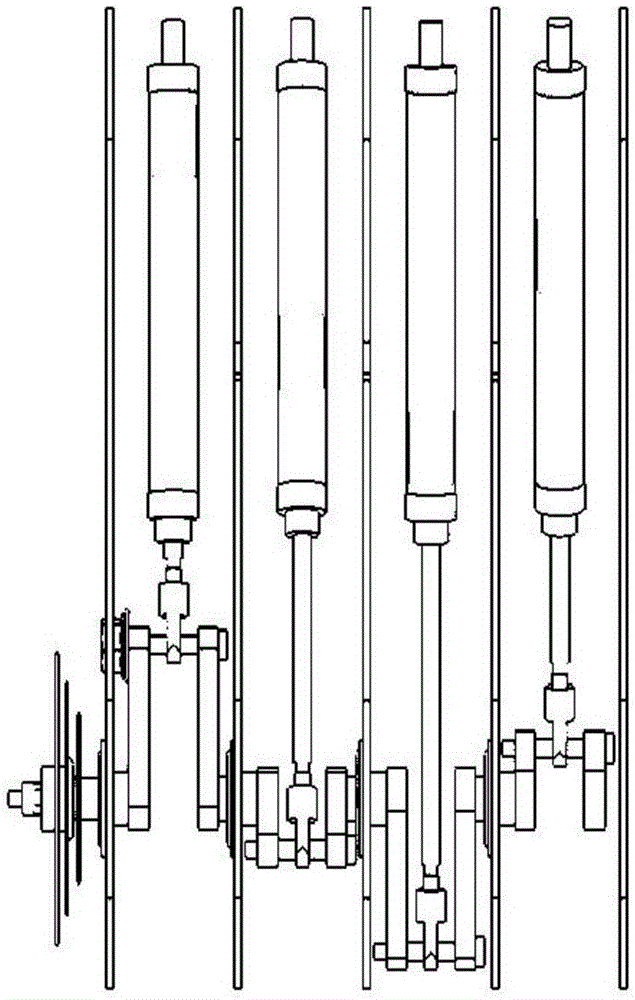

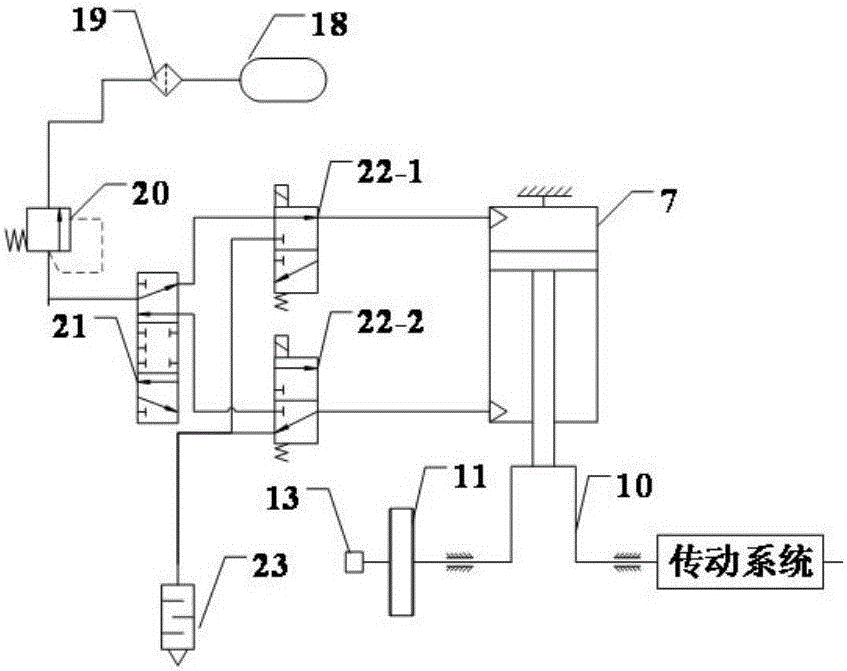

[0018] Combined with Figure 1, Figure 4 to Figure 7 , The cylinder is a single-piston rod tail pin type double-acting cylinder 7, the first bracket plate 4 and the second bracket plate 8 are fixed by stud bolts, and the cylinder is connected to the tail shaft 6 to connect the single-piston rod tail pin type double-acting cylinder. 7 is connected with the combination bracket plate, the cylinder piston rod is connected with the piston rod connecting joint 5 with low thread, the piston rod joint 5 and the connecting shaft of the piston rod are axially positioned and fixed through two small sleeves, and the connecting shaft 9 of the piston rod is connected with the crank 310 turn connection.

[0019] The cylinder piston rod connection joint 5 is installed into the piston rod connection shaft 9, two cranks 310 are installed at both ends of the connection shaft, and the other end of the crank is installed into the crankshaft output shaft 1 and the inertia wheel shaft 12 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com