Method for filtering a position signal of a position sensor of a clutch actuation device

A clutch manipulation, displacement sensor technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as displacement and vibration that are difficult to measure accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

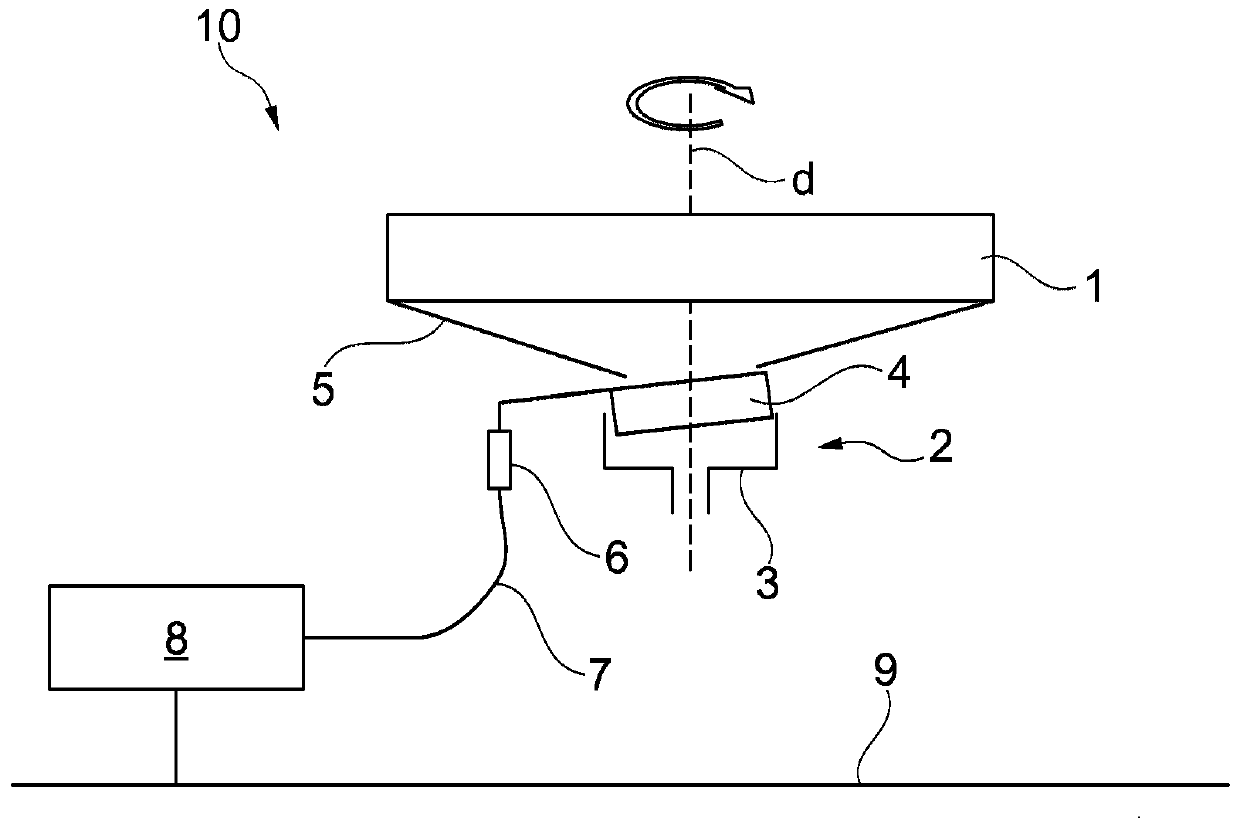

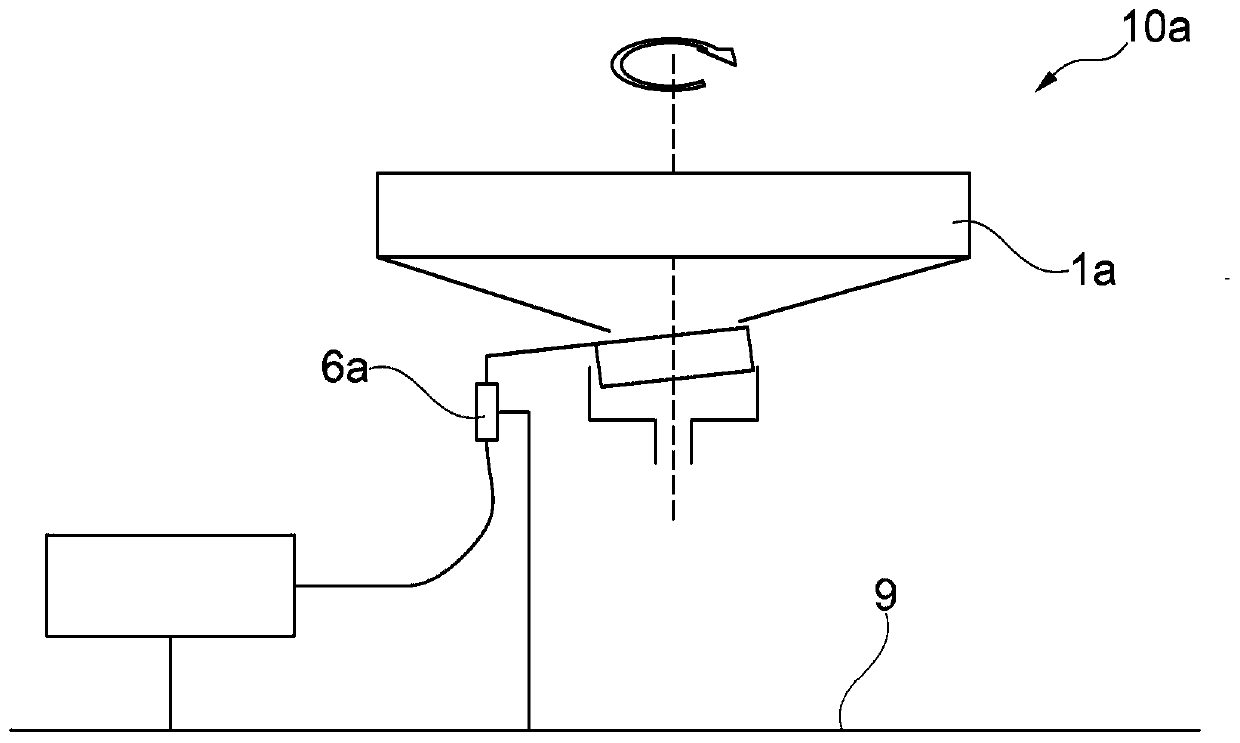

[0033] figure 1 A device 10 is shown schematically with a friction clutch 1 arranged about an axis of rotation d and having a clutch actuating device 2 . In the exemplary embodiment shown, the clutch actuating device 2 is designed as a clutch auxiliary cylinder 3 with a piston 4 . The piston 4 acts on the diaphragm spring 5 to actuate the friction clutch 1 with an axial displacement along the axis of rotation d. Axial displacement is detected by sensor 6 . The displacement signal is transmitted to the controller 8 through the cable 7 to control the friction clutch 1, and the controller is connected to a signal bus 9 such as a CAN bus. Piston 4 is tilted due to manufacturing or assembly-induced misalignment of diaphragm spring 5 . Since the displacement sensor 6 is arranged on the outside of the piston 4, the tilting of the piston 4 is additionally amplified in the displacement signal.

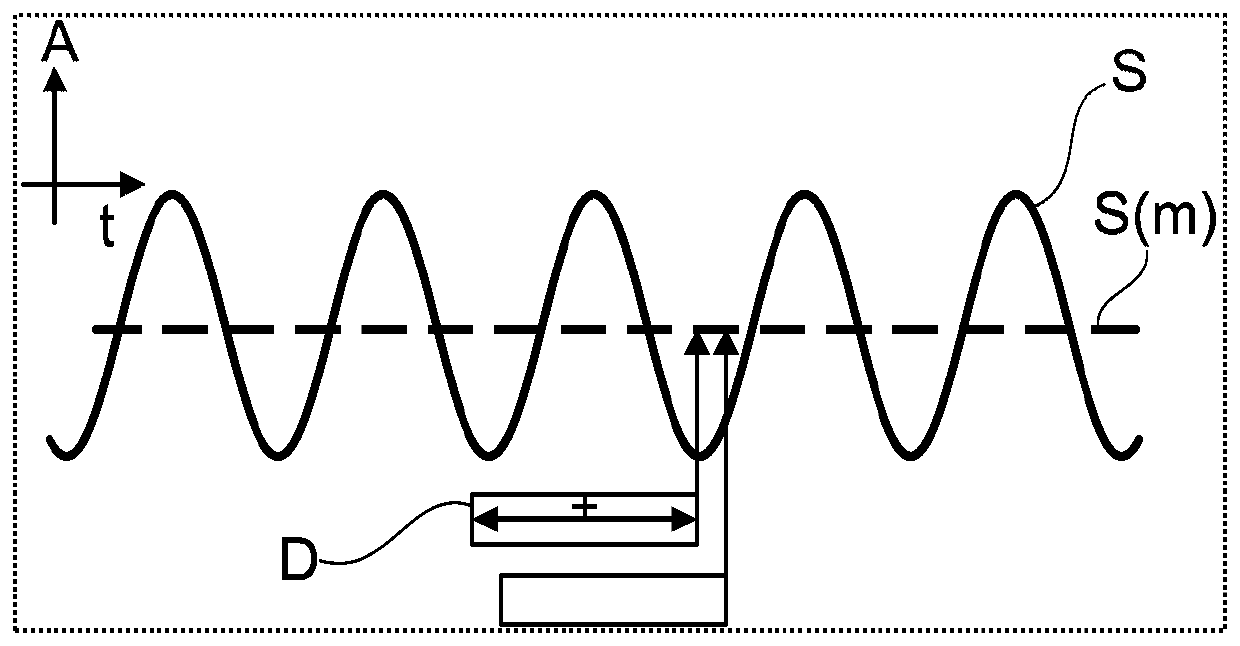

[0034]Since the friction clutch 1 rotates around the axis of rotation d at a predeterm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com