Method for improving anode aluminum foil current collector performance

A technology of current collector and aluminum foil, applied in electrode collector coating, electrode carrier/current collector, electrode manufacturing, etc., can solve the problems of low bonding strength and poor bonding application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

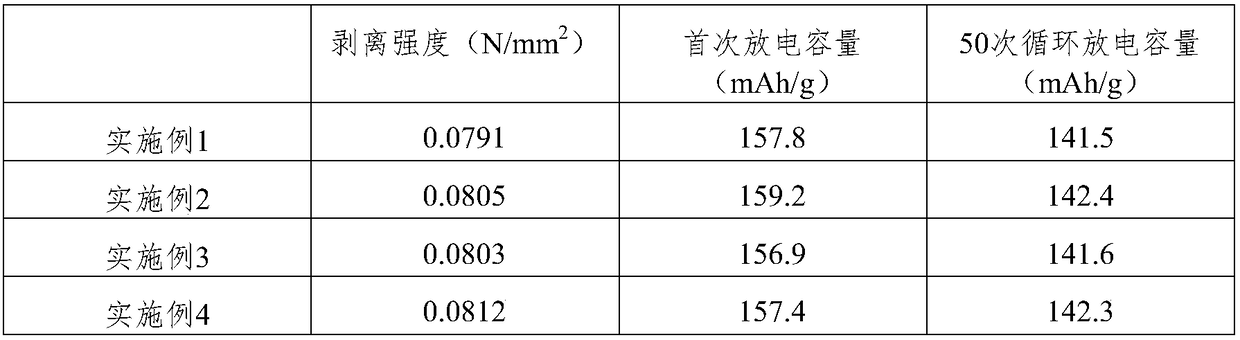

Examples

Embodiment 1

[0021] A method for improving the performance of a positive electrode aluminum foil current collector, comprising the following steps:

[0022] (1) Soak the aluminum foil in a pretreatment solution at 40°C for 10s;

[0023] (2) Put the aluminum foil treated in step (1) in a sodium fluoroborate solution, treat it at 80° C. for 30 seconds, rinse it with clean water, and dry it in the air.

[0024] Described pretreatment liquid is made up of sodium sulfate 2g / L, potassium acetate 1g / L, octylphenol polyoxyethylene ether 5g / L and water;

[0025] Described sodium fluoroborate solution is made up of sodium dihydrogen phosphate 4g / L, ammonium fluoride 1g / L, zinc acetate 3g / L, sodium fluoroborate 14g / L and water.

Embodiment 2

[0027] A method for improving the performance of a positive electrode aluminum foil current collector, comprising the following steps:

[0028] (1) Soak the aluminum foil in the pretreatment solution at 50°C for 20s;

[0029] (2) Put the aluminum foil treated in step (1) in a sodium fluoroborate solution, treat it at 100°C for 50 seconds, rinse it with clean water, and dry it in the air.

[0030] Described pretreatment liquid is made up of sodium sulfate 8g / L, potassium acetate 3g / L, octylphenol polyoxyethylene ether 7g / L and water;

[0031] The sodium fluoroborate solution is composed of potassium dihydrogen phosphate and calcium dihydrogen phosphate mixed 11g / L, ammonium fluoride 5g / L, potassium acetate 8g / L, sodium fluoroborate 17g / L and water.

Embodiment 3

[0033] A method for improving the performance of a positive electrode aluminum foil current collector, comprising the following steps:

[0034] (1) Soak the aluminum foil in a pretreatment solution at 45°C for 15s;

[0035] (2) Put the aluminum foil treated in step (1) in a sodium fluoroborate solution, treat it at 90°C for 40 seconds, rinse it with clean water, and dry it in the air.

[0036] Described pretreatment liquid is made up of sodium sulfate 6g / L, potassium acetate 2g / L, octylphenol polyoxyethylene ether 6g / L and water;

[0037] Described sodium fluoroborate solution is mixed 8g / L by the mass ratios such as calcium dihydrogen phosphate, potassium dihydrogen phosphate, sodium dihydrogen phosphate, ammonium fluoride 3g / L, zinc acetate and potassium acetate etc. quality mixes 5g / L, Sodium fluoroborate 16g / L and water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com