A transformer oil level gauge identification method based on a patrol inspection robot

A technology for inspection robots and transformer oil, which is applied in character and pattern recognition, instruments, calculations, etc., can solve problems such as inaccurate display recognition, achieve high position repeatability, improve inspection efficiency, and reduce false detection problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

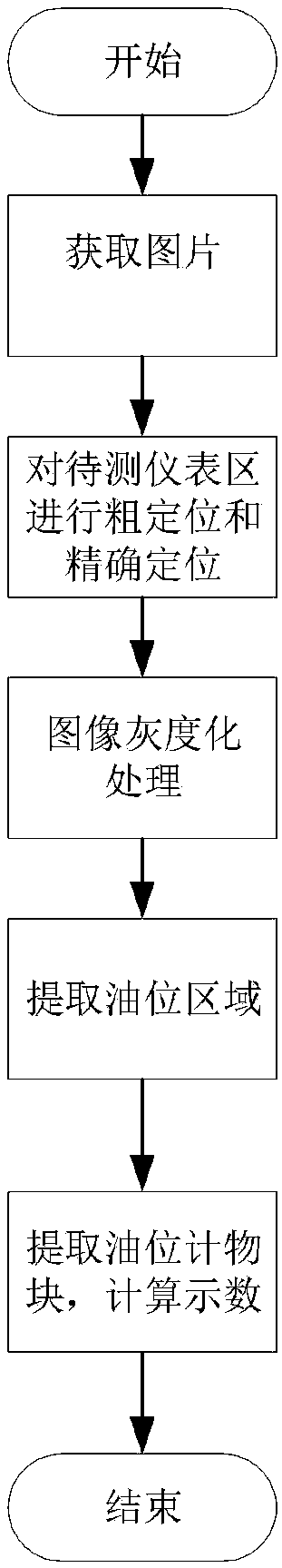

[0052] A method for identifying a transformer oil level gauge based on an inspection robot, comprising the following steps:

[0053]Step 1. For each inspection point, select an image centered on the instrument taken at the inspection point as a template image, and the inspection robot goes to the inspection point to obtain a picture of the instrument to be inspected;

[0054] Step 2. Carry out rough positioning and precise positioning of the target instrument area to be detected, and screen the target candidate area to obtain the final target, specifically:

[0055] Step 2.1, use Merlin Fourier transform and phase correlation technology to roughly locate the target instrument area in the picture of the instrument to be detected;

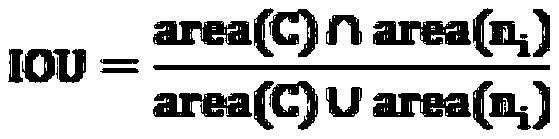

[0056] Step 2.2, use the machine learning method to accurately locate the target instrument area, send the image to be detected to the trained classifier, and obtain several target candidate areas; the trained classifier is a classifier trained using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com