Chemical-fiber-silk rapid cooling equipment

A technology of rapid cooling and chemical fiber yarn, applied in the field of chemical fiber yarn, can solve the problems of low resource utilization rate, low cooling rate, long cooling time, etc., and achieve the effect of improving utilization rate, improving heat dissipation rate, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

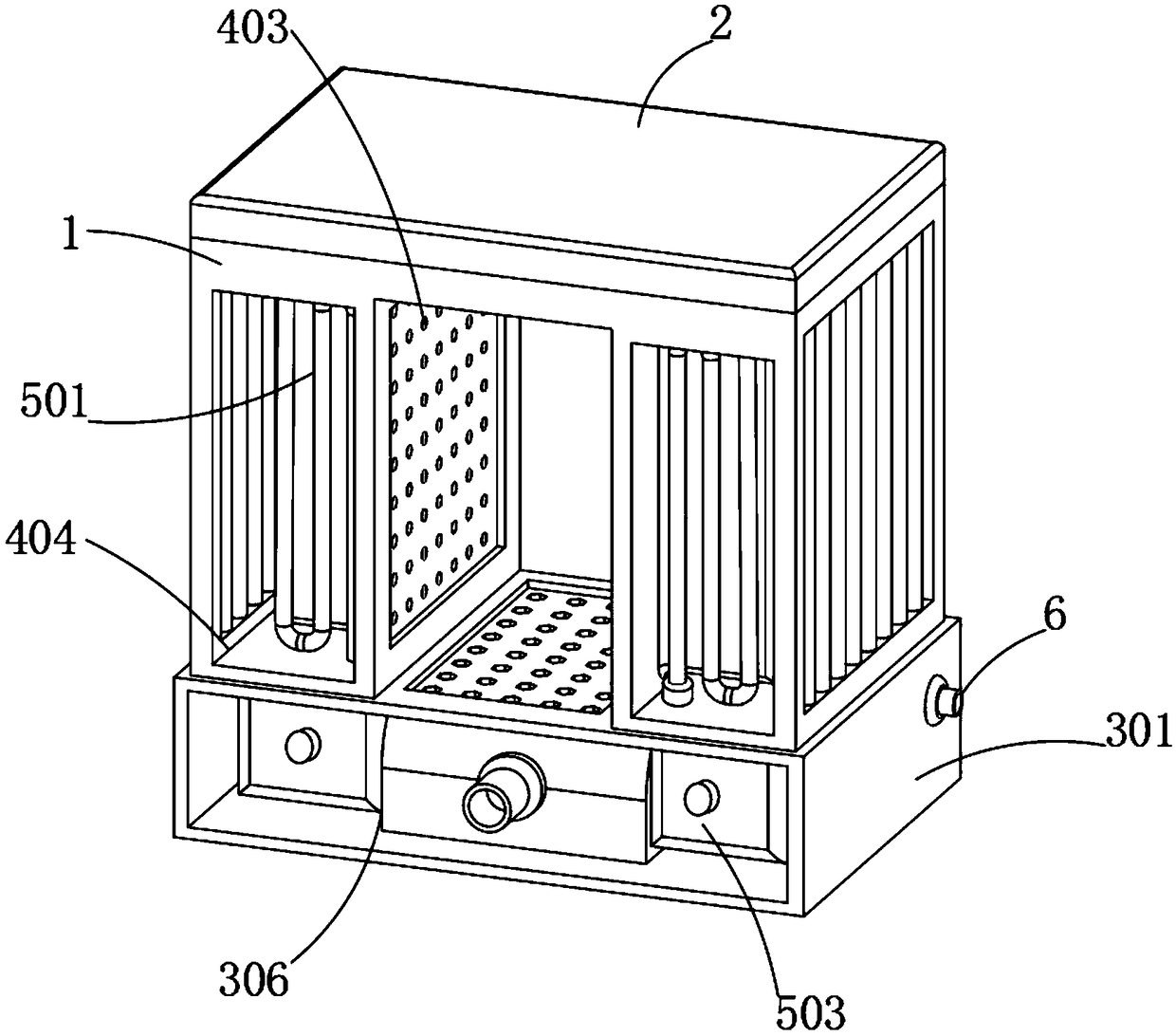

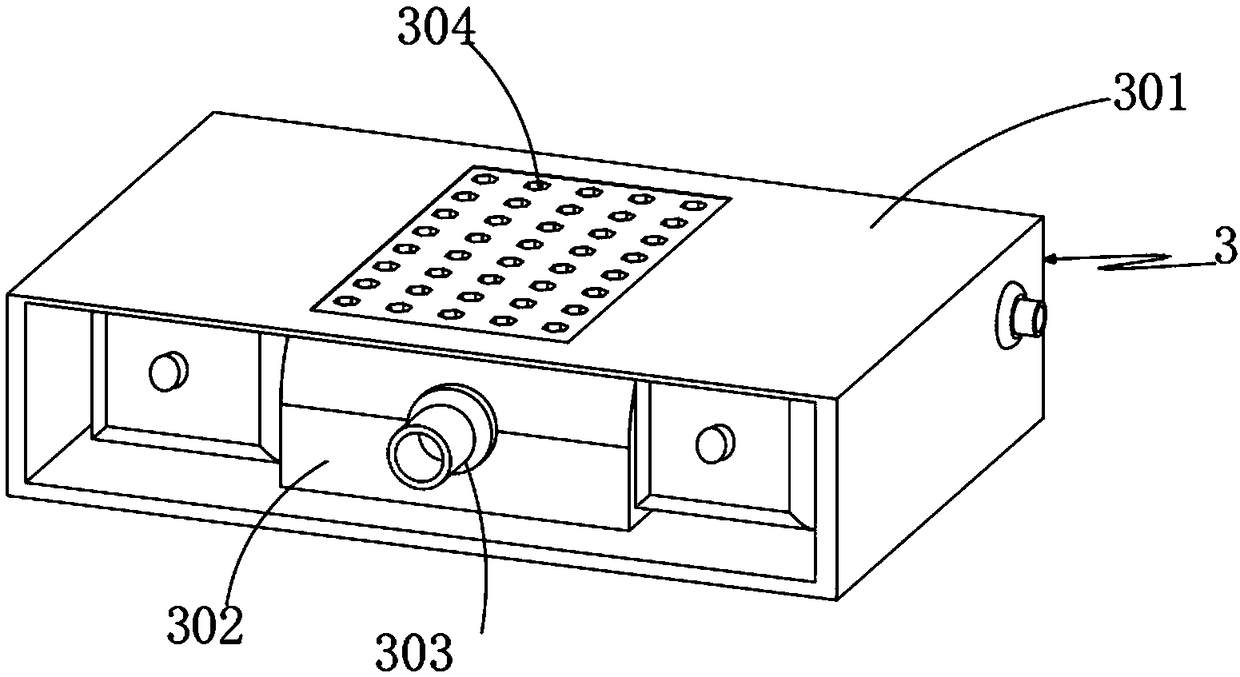

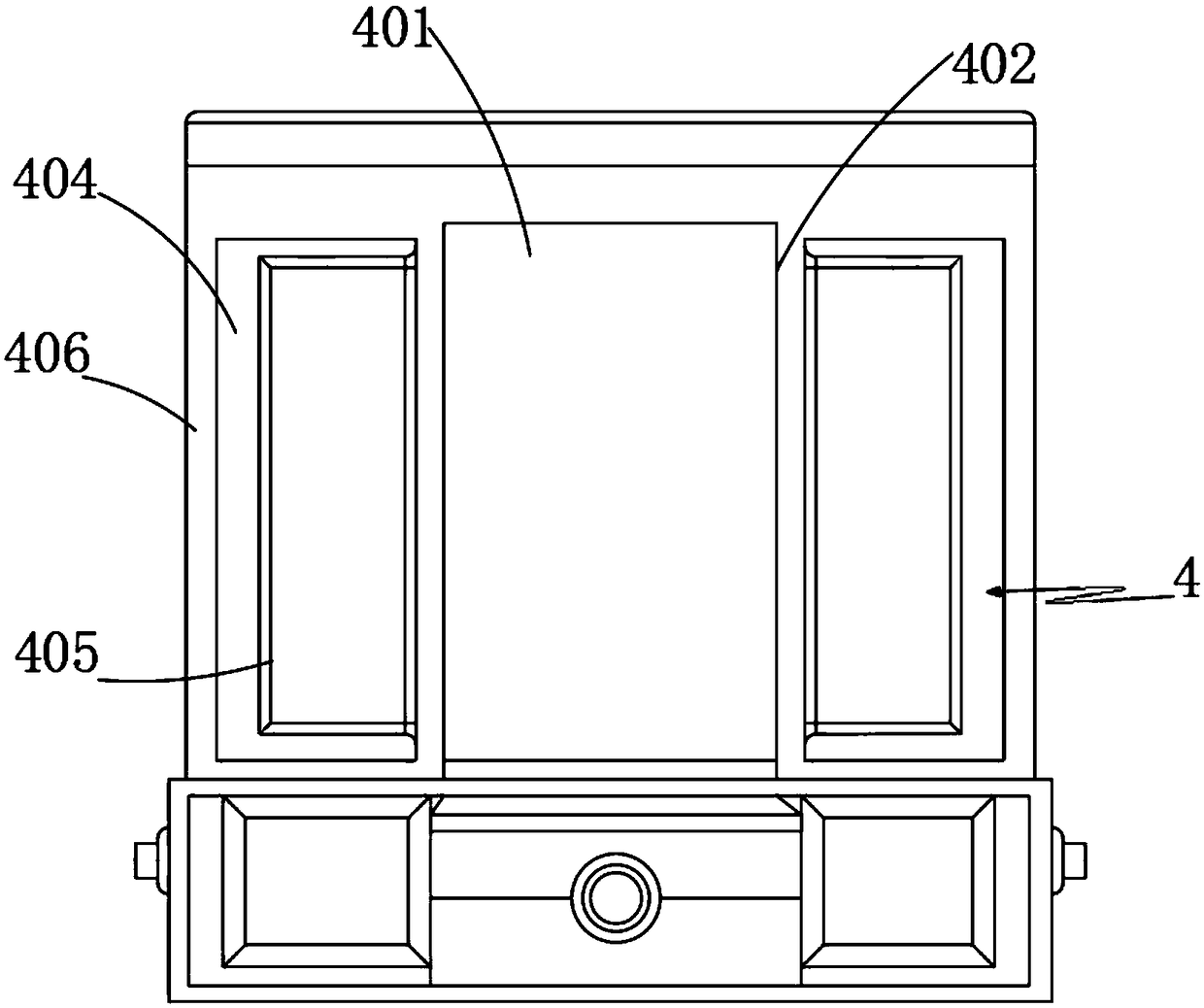

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a chemical fiber filament rapid cooling equipment, including a cooling box 1, in order to facilitate the maintenance of the cooling box 1, the top of the cooling box 1 is equipped with a box cover 2, and the inside of the cooling box 1 is installed The air-cooled assembly 4, the air-cooled assembly 4 includes an air flow channel 401, a partition plate 402, a porous rectifying plate 403, a cooling chamber 404, a chemical fiber storage box 405 and an air outlet 406, and an air flow channel 401 is provided at the center of the cooling box 1, Both ends of the air flow chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com