A kind of hydrocarbon rich fuel propellant and preparation method thereof

A hydrocarbon fuel and propellant technology, which is applied in the production of offensive equipment, explosives, compressed gas, etc., can solve problems such as restricting application, and achieve the effects of improving storage performance, wide sources and high gas generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention also discloses a method for preparing a hydrocarbon-rich fuel propellant, comprising the following steps:

[0045] (1) Weighing: Accurately weigh each component in a dry environment for use;

[0046] (2) Mixing: Add functional additives to the adhesive and mix manually to obtain a premixed slurry, then add metal fuel, hydrocarbon fuel, and oxidant to the vertical mixer in turn and mix evenly, then add curing agent to continue Mixing, control the mixing temperature at 30°C to 50°C, and the mixing time at 70min to 110min, until the system is completely mixed and evenly discharged;

[0047] (3) Casting and curing: Vacuum pour the slurry and cure it in a dry environment at 50°C to 70°C for 5 to 8 days to obtain a propellant product.

[0048] According to the characteristics of hydrocarbon fuel solid propellants, adjusting the relevant properties of hydrocarbon fuel-rich propellants can make them widely used in a variety of advanced air-breathing power devices...

Embodiment 1

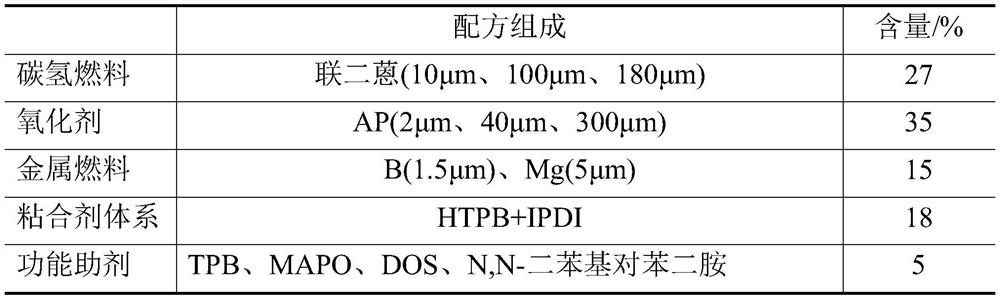

[0050] (1) Propellant formula

[0051]

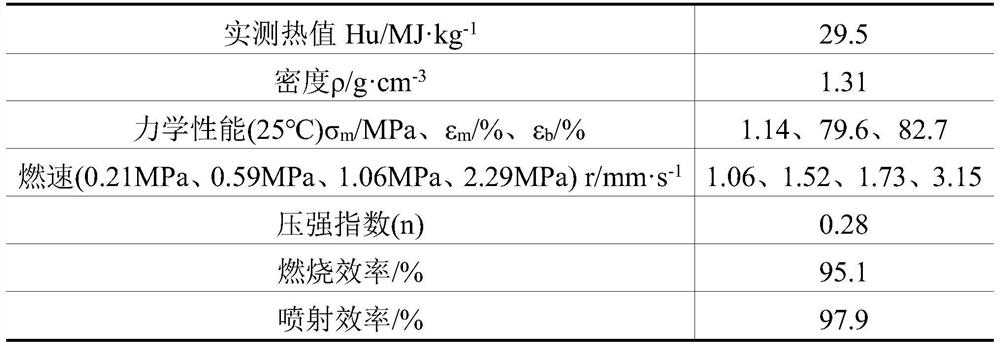

[0052] (2) Propellant performance

[0053]

[0054] Can know from embodiment 1, measured calorific value=29.5MJ L -1 , Combustion efficiency = 95.1%, excellent combustion performance.

Embodiment 2

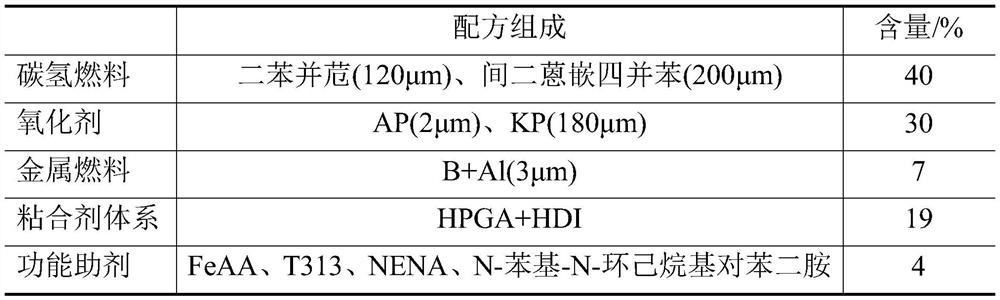

[0056] (1) Propellant formula

[0057]

[0058] (2) Propellant performance

[0059]

[0060] Can know from embodiment 2, measured calorific value=31.9MJ L -1 , Combustion efficiency = 96.0%, excellent combustion performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com