Sludge dewatering device

A sludge dewatering and sludge feeding technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Low energy consumption, good use value, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

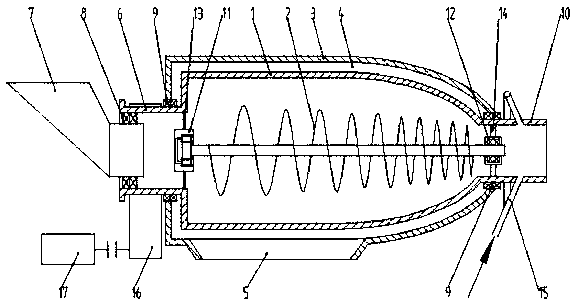

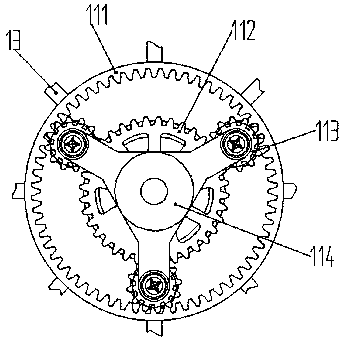

[0035] like figure 1 and figure 2As shown, a sludge dewatering device includes a centrifugal cylinder 1, a screw auger 2 and a casing 3; the centrifugal cylinder 1 and the casing 3 form a certain dehydration gap 4, and the casing 3 is sealed and connected to the centrifugal cylinder through a bearing 2 9 1, so that the shell 3 can remain relatively stationary during the high-speed rotation of the centrifugal cylinder 1, and the centrifugal cylinder 1 can rotate at a high speed relative to the shell 3 under the action of the driving device, and the cylinder wall of the centrifugal cylinder 1 is a filterable cylinder wall; The screw stacking screw 2 is installed in the centrifugal cylinder 1 through the transmission assembly 11, and rotates with the centrifugal cylinder 1 at a constant speed ratio; along the direction of the rotation axis of the centrifugal cylinder 1, the two ends of the centrifugal cylinder 1 are respectively set There is a mud inlet 7 and a mud outlet 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com