Luffing crane boom

A technology of cranes and booms, which is applied in the field of luffing crane booms, can solve problems such as crane damage, and achieve the effect of convenient lifting and lifting objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

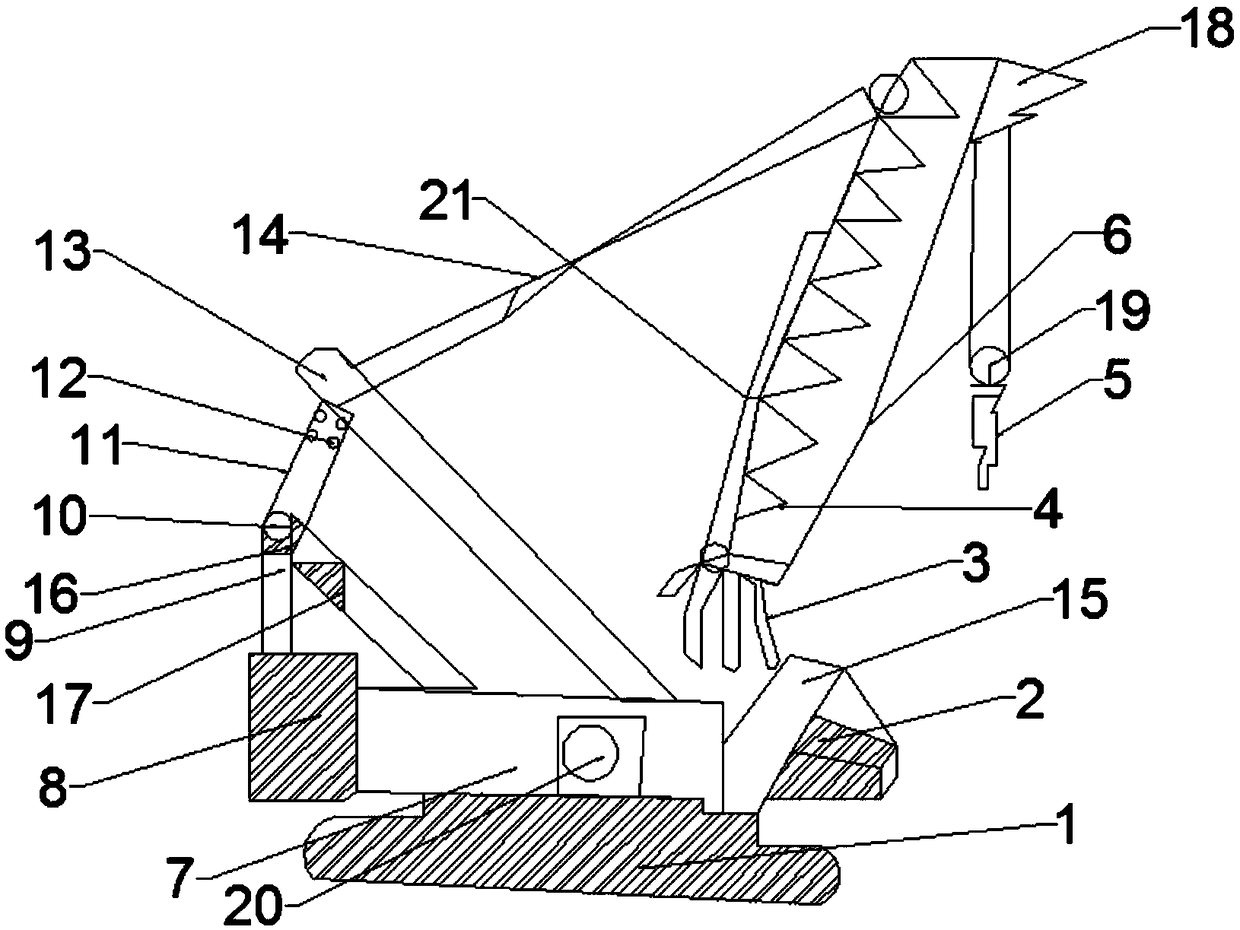

[0014] see figure 1 , the present invention provides a technical solution: a luffing crane boom, including a hydraulic cylinder 10 and a boom 6, the upper surface of the hydraulic cylinder 10 is fixed with a telescopic boom 11, and the telescopic boom 11 The other end is provided with a mast 13, and an engine motor 16 is also fixedly installed on the front of the hydraulic cylinder 10. A herringbone frame 9 is also installed on the bottom surface of the hydraulic cylinder 10, and an orientation sensor 17 is installed on the upper surface of the hydraulic cylinder 9. The lower end of orientation sensor 17 is equipped with counterweight device 8, and this counterweight device 8 is equivalent to a lifting lever, can reduce the bearing force on the jib 6, and herringbone frame 9 is fixedly installed on the turntable 7, on the turntable 7 The boom system monitoring device 20 is installed on the surface, which can monitor the moving range of the boom 6 at all times, and the disembar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com