Double-blade turbulent efficient stirring device for calorimeter

A stirring device and double-blade technology are applied in the field of coal quality analysis and detection equipment, which can solve the problems of low stirring efficiency, long time for water temperature to reach uniformity, heat measurement interference, etc., so as to improve measurement accuracy, avoid shaking and break easily, Reduce the effect of stirring heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

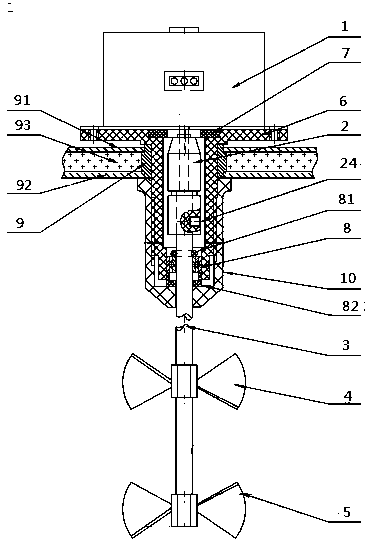

[0031] Embodiment 1: A double-blade turbulent high-efficiency stirring device for a calorimeter, see figure 1 and figure 2 , including motor 1, shaft coupling 2, glass fiber stirring rod 3, forward propeller stirring blade 4 and reverse propeller stirring blade 5; the rotating shaft of the motor 1 is connected to the glass fiber stirring rod 3 through the shaft coupling 2, and the glass The fiber stirring rod 3 is equipped with a positive paddle stirring blade 4 and a reverse paddle stirring blade 5 .

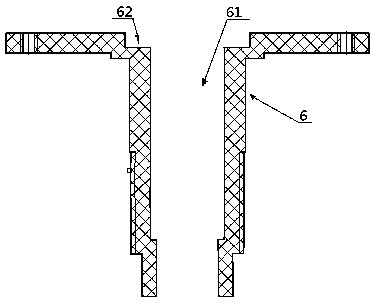

[0032]As a specific implementation description of this embodiment, the motor 1 is coaxially fixed by the fixing seat 6 and the positioning sleeve 7; the middle part of the fixing seat 6 is a mounting cavity 61 through which the upper and lower ends are connected, and the upper port of the mounting cavity 61 is provided with a positioning sleeve The installation slot 62 and the positioning sleeve 7 are arranged between the installation slot 62 and the motor 1 .

[0033] As a ...

Embodiment 2

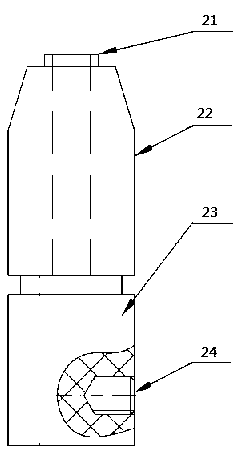

[0042] Embodiment 2: The difference from Embodiment 1 is that the coupling 2 is a miniature hoop-type copper core coupling, such as image 3 As shown, the coupling 2 includes a copper core positioning ferrule 21, a lock nut 22, a copper core coupling body 23 and a flat end set screw 24, and the upper end of the copper core coupling body 23 is connected to a copper core positioning A ferrule 21, the outer end of the copper core positioning ferrule 21 is equipped with a lock nut 22, and the copper core coupling body 23 is provided with a flat end set screw 24; the copper core positioning ferrule 21 is sleeved with a motor 1, and locked by a lock nut 22, the lower end of the copper core coupling body 23 is sleeved with a glass fiber stirring rod 3, and locked by a flat-end set screw 24.

[0043] As a specific implementation description of this embodiment, the size model of the flat end set screw 24 is M3*4.

[0044] The double-blade turbulent flow high-efficiency stirring device...

Embodiment 3

[0045] Embodiment 3: The difference from Embodiment 1 is that the distance between the forward propeller stirring blade 4 and the reverse propeller stirring blade 5 is 10 mm. With this spacing design, the range of turbulent flow generated by the stirring is relatively small, and the stirring heat is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com